Stress relief aging device

A stress-relieving and aging technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of limited ability to reduce residual stress, poor flexibility, and bulky vibration table, to reduce residual stress, occupy small space, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

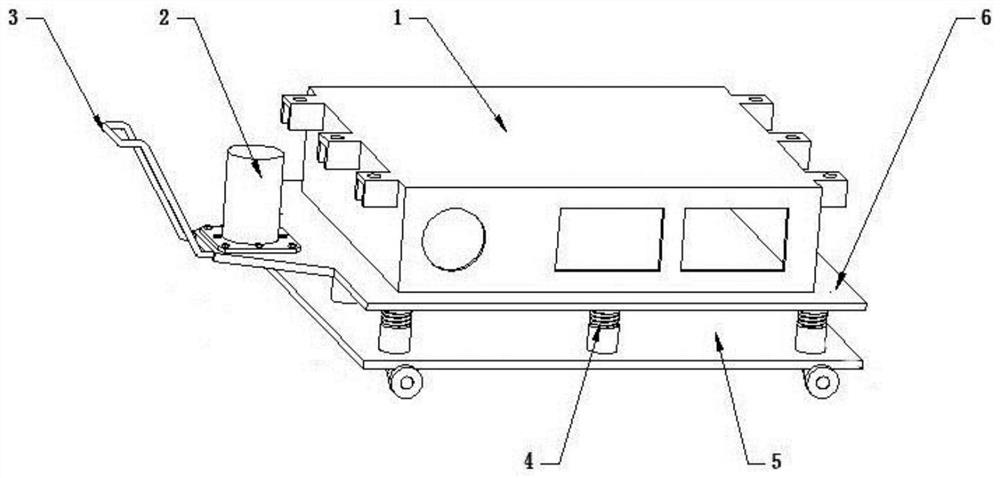

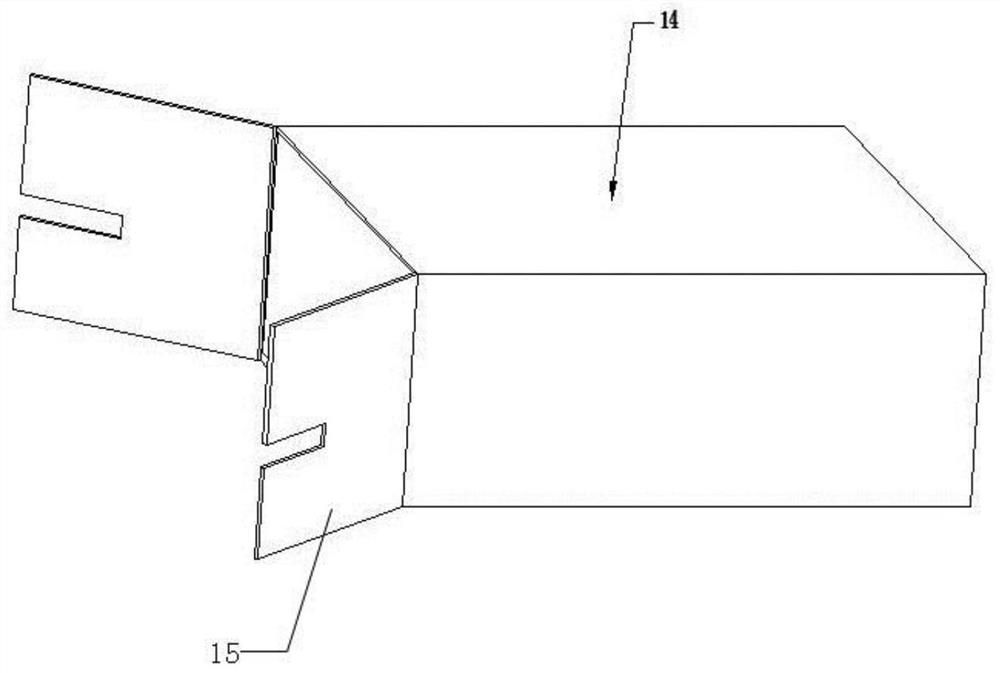

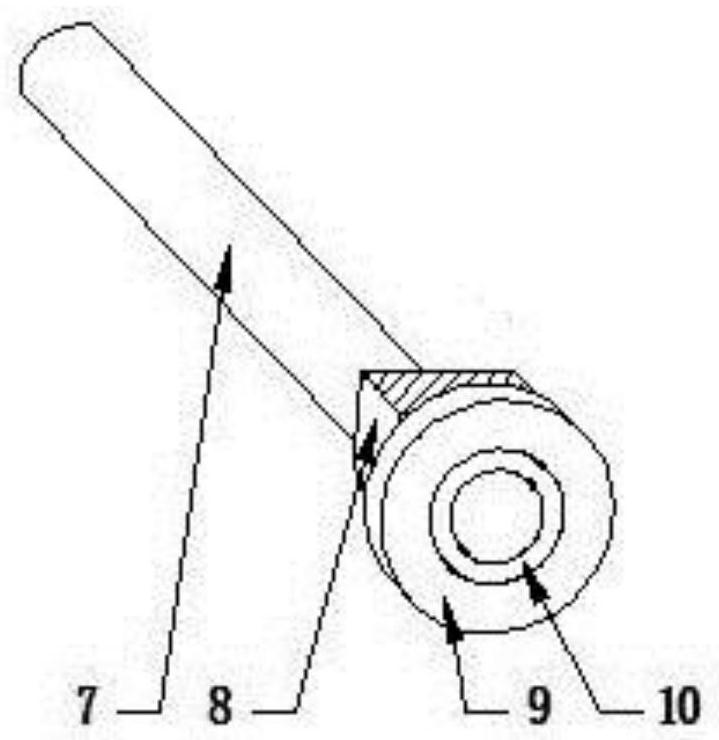

[0031] Such as Figure 1-Figure 4 As shown, the present embodiment provides a stress relief aging device, which includes a thermal aging furnace 14 and a mobile vibrating table, the mobile vibrating table includes a traveling mechanism, and the mobile vibrating table moves into or out of the thermal aging furnace 14 through the traveling mechanism .

[0032] When it is necessary to perform aging treatment on the workpiece 1, the workpiece 1 is first fixed on the mobile vibrating table, and the workpiece 1 is sent into the thermal aging furnace 14 through the mobile vibrating table for simultaneous thermal and vibration loading, so that the workpiece 1 is subjected to aging treatment. Thermal and vibration comprehensive aging treatment to reduce welding residual stress of workpiece 1. The present invention overcomes the single stress relief device in the prior art thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com