Preparation method of citral

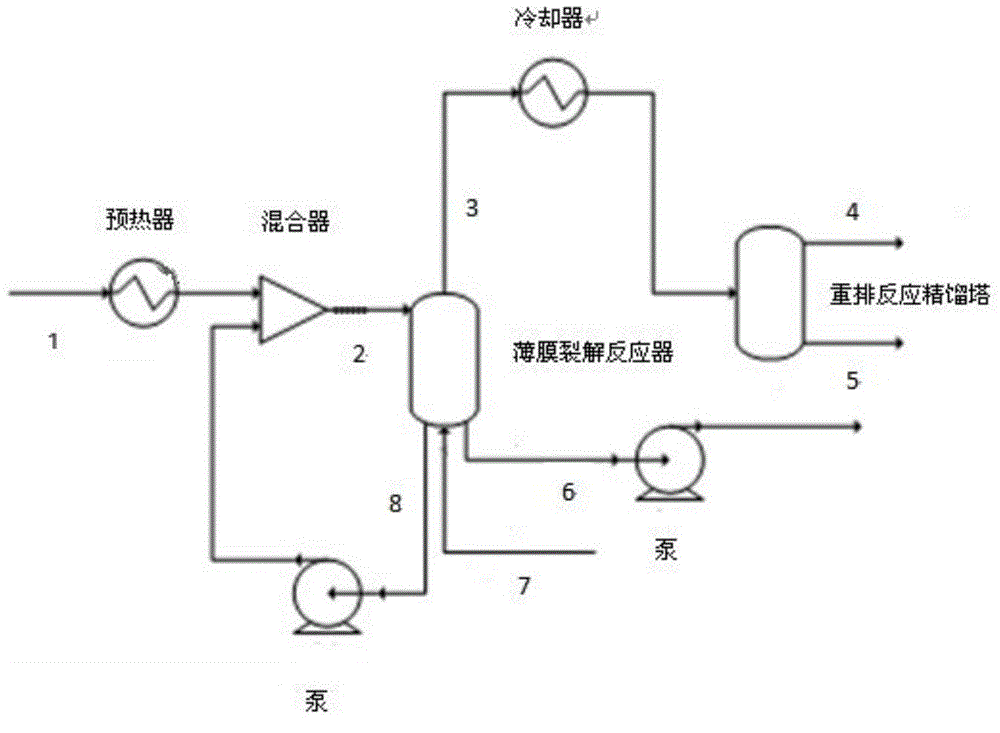

A technology of citral and aldehyde diprenyl acetal, which is applied in the preparation of organic compounds, hydrolysis preparation, and chemical methods for reacting liquids with liquids, etc., can solve the problem of reduced cracking reaction rate, long residence time, and corrosion. Large and other problems, to achieve the effect of reducing residence time, fast reaction rate, and small liquid holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

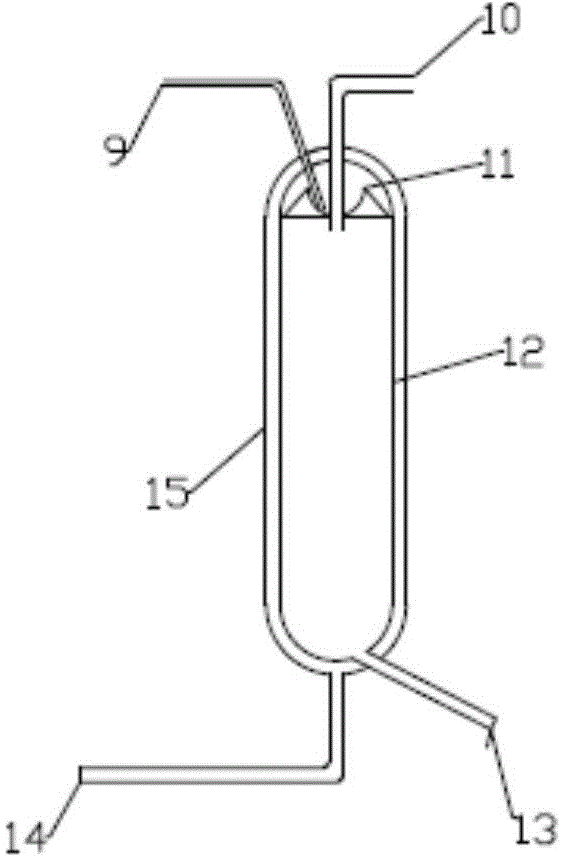

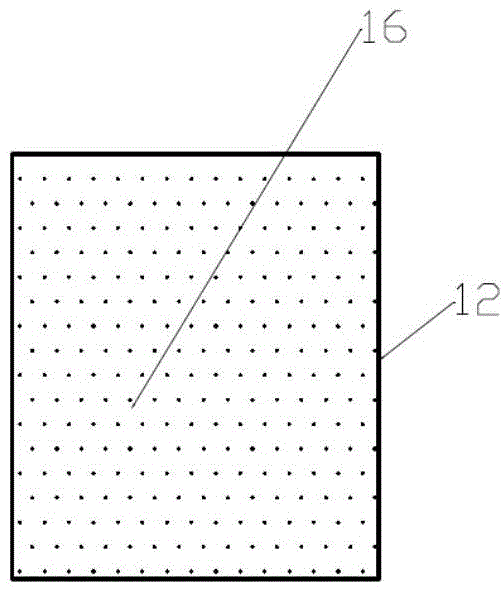

[0078] The inner diameter of the thin-film cracking reactor is 50mm, the outer diameter is 60mm, and the height is 1m. The distance between the largest circle at the bottom of the liquid distributor of the thin-film cracking reactor and the inner wall of the reactor is 0.05mm, and the cone angle of the liquid distributor is 100 degrees. The ratio of the spherical radius of the liquid storage tank to the circular radius of the conical bottom of the liquid distributor is 0.45, and the through holes opened on the inner shell wall of the thin film cracking reactor are evenly distributed in a matrix, and the distance between each through hole is 0.5mm. 0.01mm. The film pyrolysis reactor carries out gas phase extraction and condensation, and then enters the reactive distillation tower. The inner diameter of the reactive distillation tower is 25mm, equipped with 1.5m Raschig ring packing, the effective number of plates is 25, and the feeding position is located at the 17th block tray...

Embodiment 2

[0080] The distance between the largest circle at the bottom of the liquid distributor of the film cracking reactor and the inner wall of the reactor is 1.55 mm, the cone angle of the liquid distributor is 90 degrees, the spherical radius of the hemispherical liquid storage tank and the radius of the cone bottom circle of the liquid distributor The ratio is 0.55, and the through-holes opened on the inner shell wall of the membrane cracking reactor are evenly distributed in a matrix, the distance between each through-hole is 5mm, and the diameter of the opening is 0.05mm. The other structures of the film cracking reactor are the same as in Example 1. The reactive distillation column is the same as in Example 1. First, heat the film cracking reactor to 150°C, then preheat the nitrogen gas 7 to 150°C and introduce it into the film cracking reactor. The nitrogen consumption is 5000ml / min. After the temperature of the device is stable, turn on the vacuum pump to reduce the system p...

Embodiment 3

[0082] The distance between the largest circle at the bottom of the liquid distributor of the film cracking reactor and the inner wall of the reactor is 0.8mm, the cone angle of the liquid distributor is 80 degrees, the spherical radius of the hemispherical liquid storage tank and the radius of the cone bottom circle of the liquid distributor The ratio is 0.7, and the through-holes opened on the inner shell wall of the membrane cracking reactor are evenly distributed in a matrix, the distance between each through-hole is 10mm, and the diameter of the opening is 2mm. The other structures of the film cracking reactor are the same as in Example 1. The reactive distillation column is the same as in Example 1. First, heat the film cracking reactor to 180°C, then preheat the nitrogen gas 7 to 180°C and introduce it into the film cracking reactor. The nitrogen consumption is 15000ml / min. After the temperature of the device is stable, turn on the vacuum pump to reduce the system press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com