Multilayer fluidized bed parsing device for conducting pneumatic material return through row tube type heat exchange and coupling of molten salt

A technology of a multi-layer fluidized bed and an analytical device is applied in the field of regeneration and utilization of industrial pollutant purifying agents, and can solve the problems of unsatisfactory thermal efficiency, unsatisfactory heat exchange effect of activated coke, unsatisfactory heat exchange effect of reactor, etc. , to achieve the effect of realizing the uniform distribution of heat source points, improving the utilization rate of the device, and saving the space occupancy rate of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

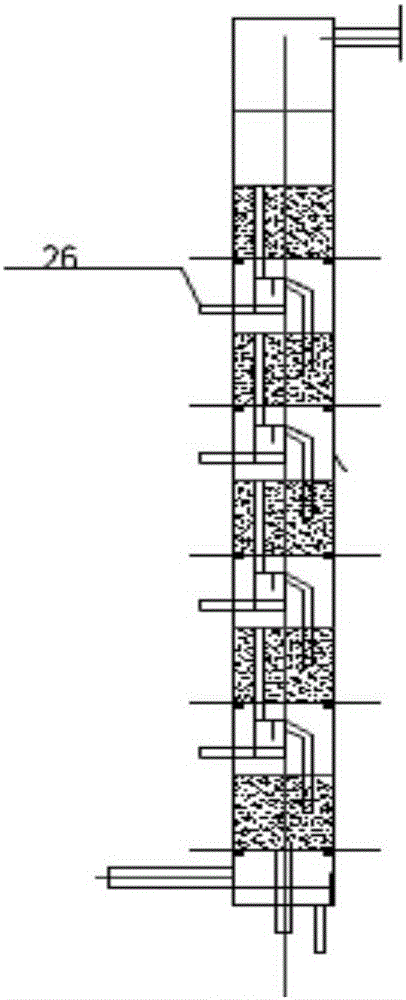

[0044] Heating device adopts fuel molten salt furnace 18, molten salt pump 19, molten salt pool 20, separator two 22, air blower 23, bag filter 24, induced draft fan two 25 and igniter 13. The fuel molten salt furnace 18 is a built-in tubular heat exchange fuel burner. According to the production scale, the small scale is a simple tube heat exchange tube, and the large scale should be a membrane wall arrangement; the fuel can be coal, natural gas, oil, biogas , coke oven gas and other fuels. The exterior of the internal heat exchange wall of the fuel molten salt furnace 18 can be coated with anti-wear cement, and the internal oxygen or air distribution needs to be supplied in stages.

[0045] The working principle of the system is as follows:

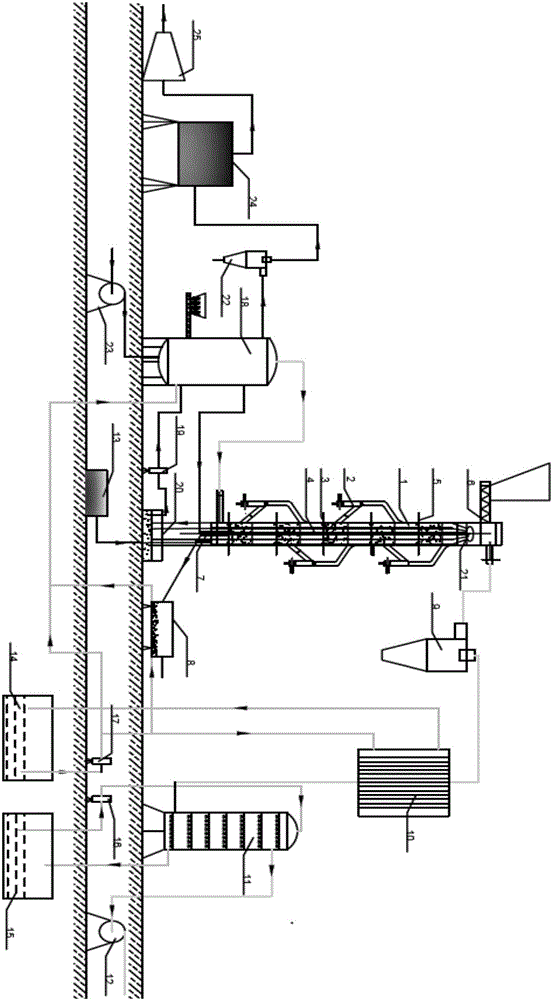

[0046] Solid particle process part: the screw feeder 6 transports the activated coke or activated carbon that needs to be regenerated to the top of the multi-layer fluidized bed body 1, and the solids are regenerated through the multi-...

Embodiment 2

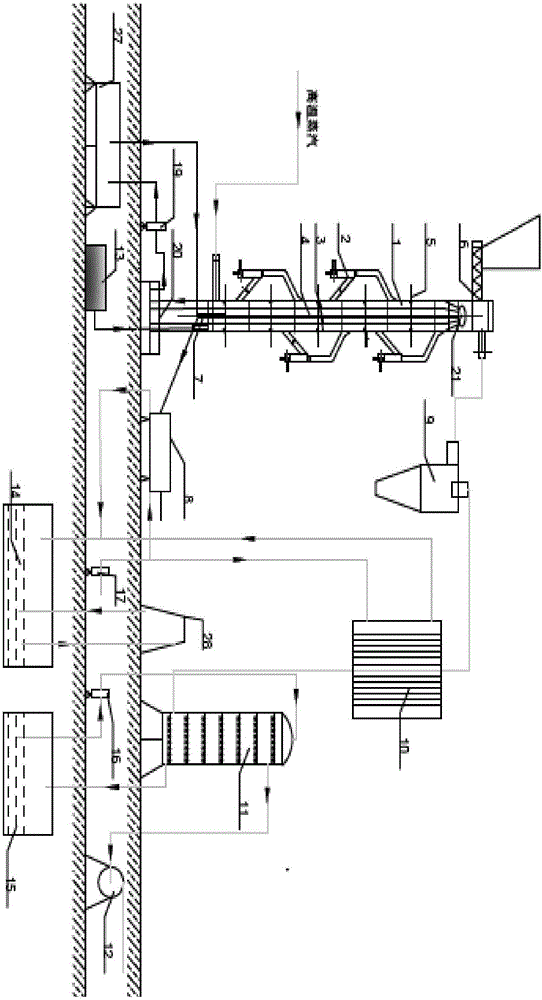

[0051] Such as figure 2 , 4 , 5, the heating device can also use an electric heating molten salt furnace 27 to replace the fuel molten salt furnace 18. The furnace 27, the molten salt pump 19, the molten salt pool 20, and the igniter 13 are connected in sequence. The electric heating molten salt furnace heats evenly, and at the same time, the power can be adjusted more accurately, the volume is simplified, and the occupied area is reduced. At the same time, the power plant can provide high-temperature steam, so the circulating water pool 14 is equipped with a water cooling tower 28 to reduce the temperature of the circulating water.

[0052] The active coke analysis method specifically includes the following steps:

[0053] Step 1: The screw feeder 6 transports the activated coke or activated carbon that needs to be regenerated to the top of the multi-layer fluidized bed 1, and the solids pass through the multi-layer fluidized bed from top to bottom in order to be regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com