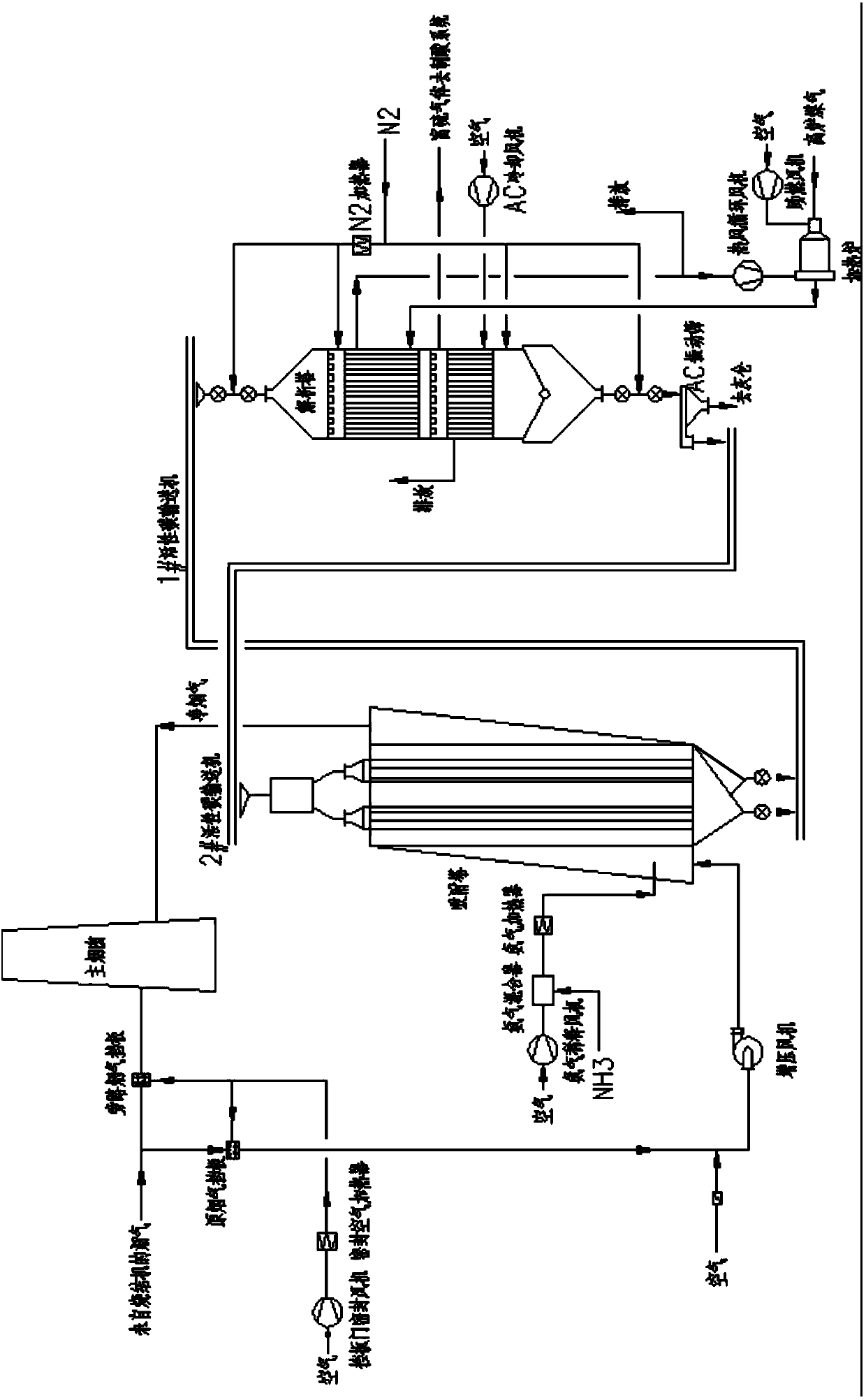

Activated carbon adsorption tower and flue gas purification method

An activated carbon adsorption tower and activated carbon technology are applied in the field of activated carbon adsorption tower and activated carbon method flue gas purification device, which can solve the problems of difficult maintenance and repair, leakage of materials, and increase in system operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

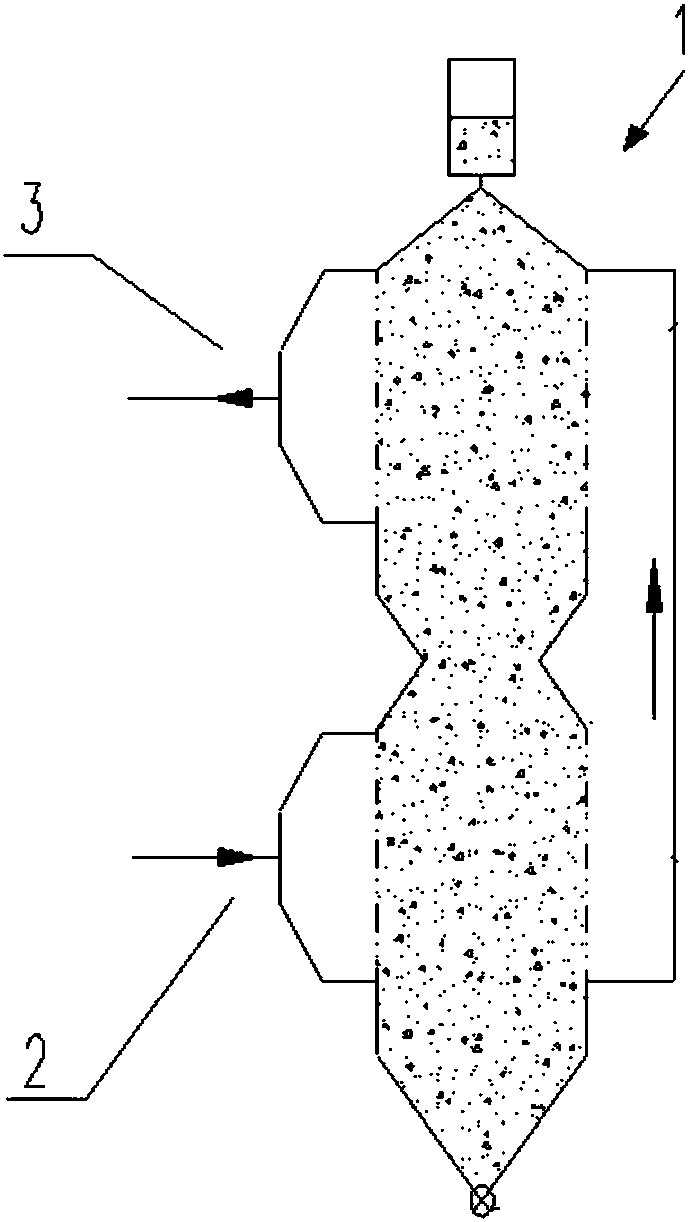

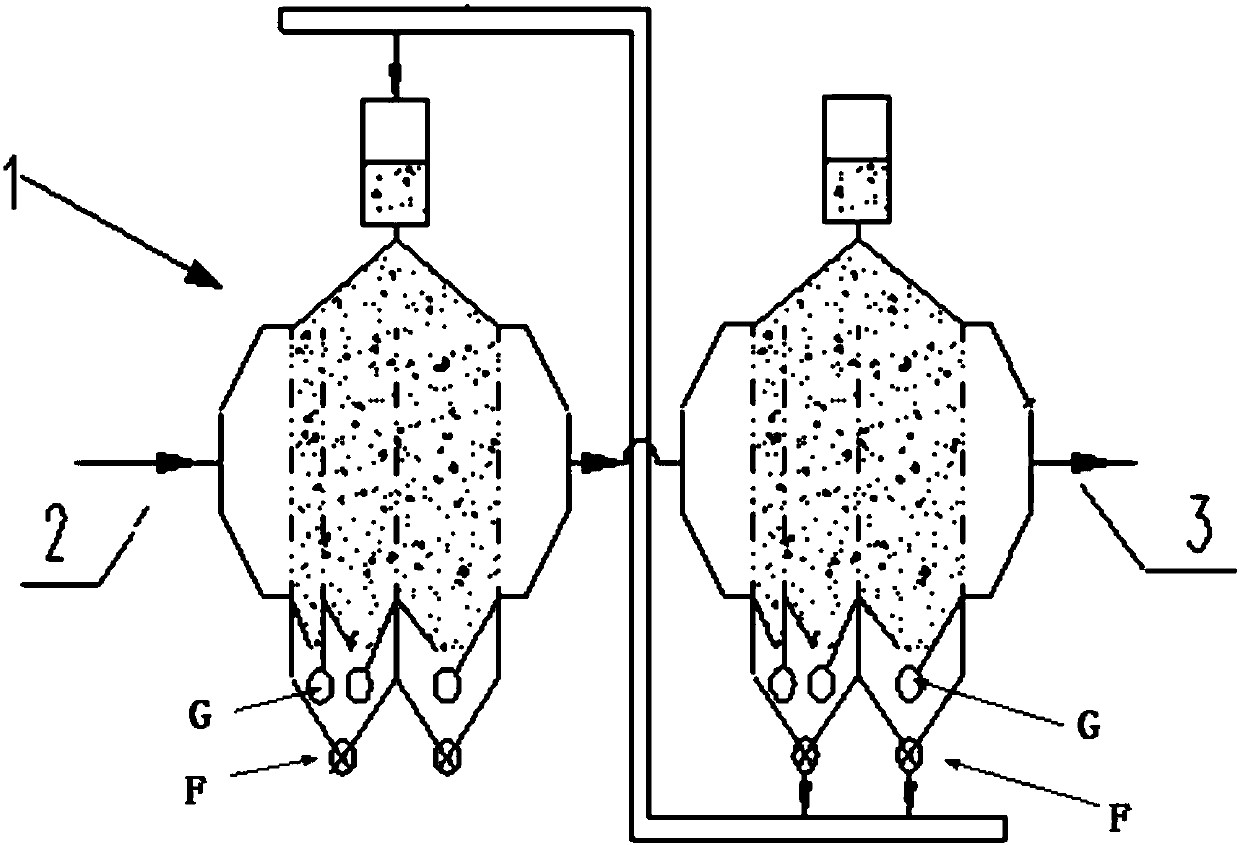

[0147] Adsorption tower such as Figure 4 As shown, it is a left and right double tower structure. The tower height of the left tower 1 or the right tower 1 as the activated carbon adsorption tower is about 25 meters.

[0148] The left tower 1 and the right tower 1 each include or have a lower activated carbon bed part A, an upper activated carbon bed part B and a middle transition zone C between the two parts, and the activated carbon adsorption tower also includes: 1 ) the first gas chamber G1 between the respective lower activated carbon bed parts A of the left tower 1 and the right tower 2, 2) the outer sides of both the lower activated carbon bed part A and the middle transition zone C of the left tower 1 (i.e. the second gas chamber G2 on the leftmost side of the middle and lower part of the twin towers and the outer sides of both the lower activated carbon bed part A and the middle transition zone C positioned at the bottom of the right tower 1 (i.e. the second gas cha...

Embodiment 2

[0173] Repeat embodiment 1, just replace discharge circular roller 106, and use a kind of novel star-wheel type active carbon discharge device, as Figure 13 shown. A discharge opening is arranged at the bottom of an activated carbon material chamber. The discharge opening is made of front baffle AC-I, rear baffle AC-II and two side panels (not shown).

[0174] The height of the main structure of the adsorption tower is 21m. The thickness of the first chamber a is 180 mm. The thickness of the second chamber b is 900 mm.

[0175] The star wheel activated carbon discharge device includes: the front baffle AC-I and the rear baffle AC-II at the lower part of the activated carbon material chamber, and the front baffle AC-I and the rear baffle AC-II at the lower part of the activated carbon material chamber. The star wheel type activated carbon discharge roller 106 below the discharge port that two side plates constitute; 12 blades 106b.

[0176] Seen from the cross-section of...

Embodiment 3

[0182] Repeat embodiment 1, just replace discharge circular roller 106, and use a kind of novel star-wheel type active carbon discharge device, as Figure 13 shown. A discharge opening is arranged at the bottom of an activated carbon material chamber. The discharge opening is made of front baffle AC-I, rear baffle AC-II and two side panels (not shown).

[0183] The height of the main structure of the adsorption tower is 21m. The thickness of the first chamber a is 160mm. The thickness of the second chamber b is 1000mm.

[0184] The star wheel activated carbon discharge device includes: the front baffle AC-I and the rear baffle AC-II at the lower part of the activated carbon material chamber, and the front baffle AC-I and the rear baffle AC-II at the lower part of the activated carbon material chamber. The star-wheel type activated carbon discharge roller 106 below the discharge port that two side plates constitute; 8 blades 106b.

[0185] Seen from the cross-section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com