Moving bed brown coal drying method and device

A technology of moving bed type and drying device, which is applied in the direction of hearth type furnace, drying solid materials, heating to dry solid materials, etc., can solve the problem of lack of engineering application and economical technology and technology, easy control of moisture in terminal drying products, and easy operation Stable troubles and other problems, to achieve the effect of improving heat transfer effect, reducing land occupation and height, and excellent adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

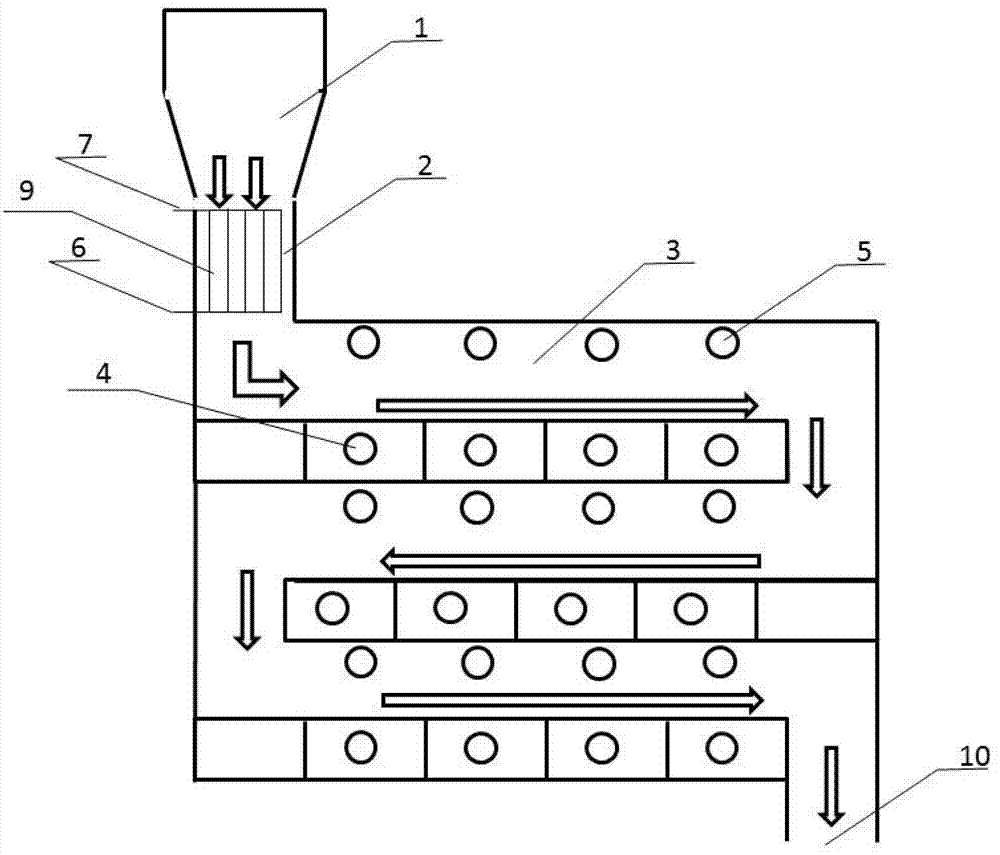

[0022] The structure, principle and specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

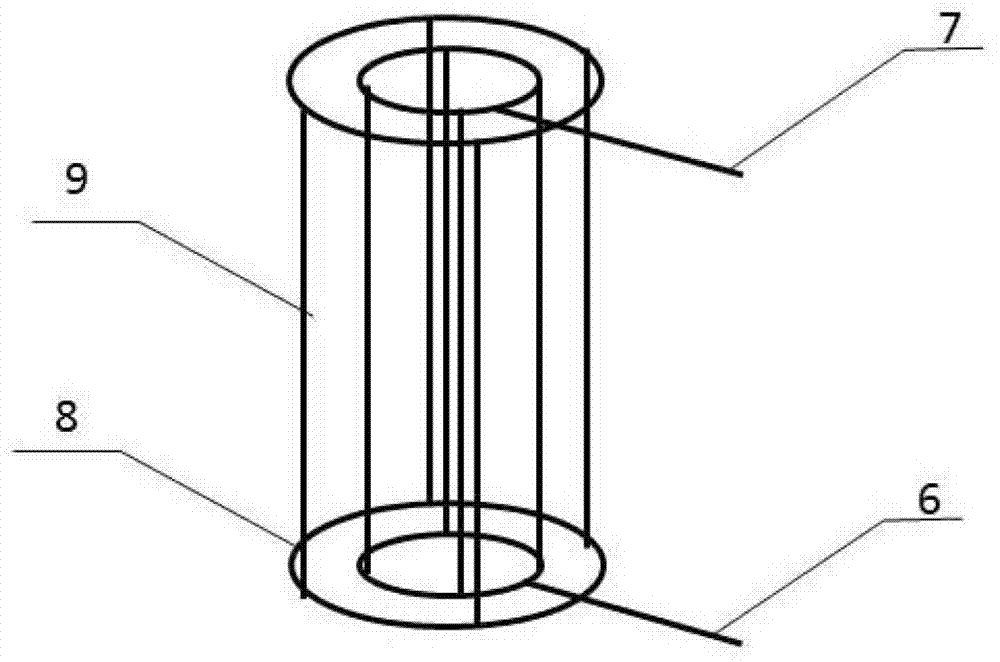

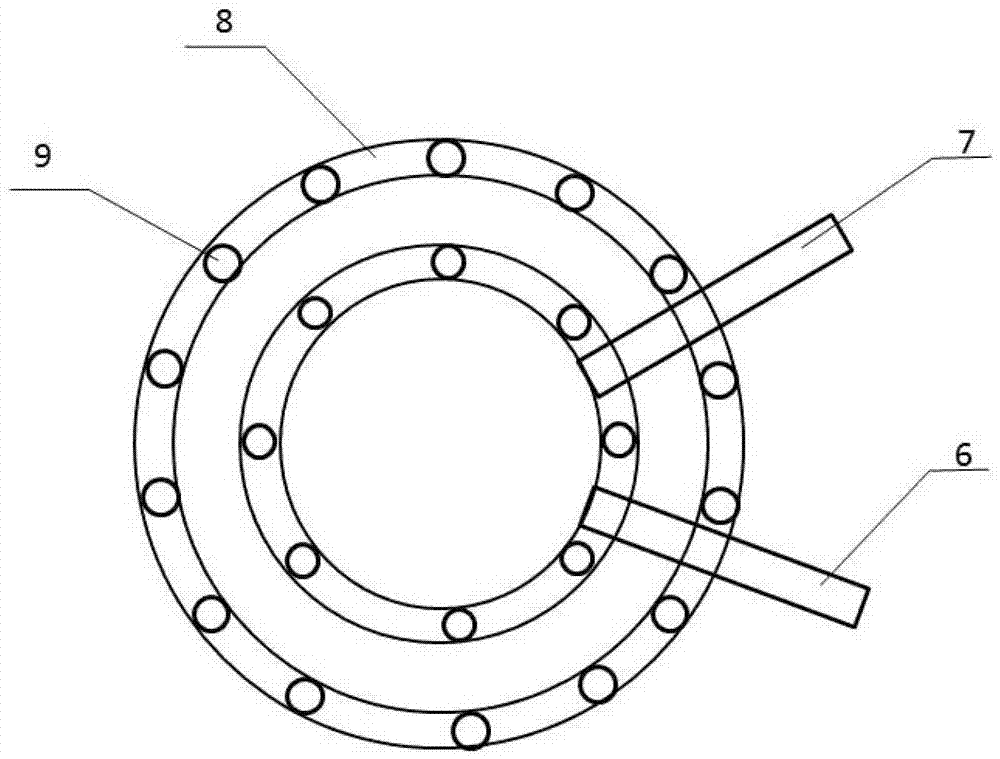

[0023] figure 1 It is a schematic diagram of the structure and principle of a moving bed lignite drying device provided by the present invention. The device includes a coal bunker 1, an indirect drying chamber 2, a direct drying chamber 3 and a separate air supply device 4; the indirect drying chamber includes a hot gas circulation pipeline 9. Hot gas inlet 6, hot gas distribution pipe 8 and hot gas outlet 7, the upper part of the indirect drying chamber is connected to the coal bunker, the lower part is connected to the direct drying chamber, and the air supply device for the sub-chambers is connected to the direct drying chamber, The direct drying chamber adopts a one-layer or multi-layer layout structure; the axial direction of the hot gas circulation pipe is consistent with the movement direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com