Device and method for producing low-ash low-sulfur carbon black through pyrolysis of waste and old tires

A technology of waste tires and low ash content, which is applied in the petroleum industry, fibrous fillers, and hydrocarbon oil treatment. It can solve the problems of increasing non-condensable combustible gas, increasing the volatile content of carbon black, and long residence time, so as to improve the carbon black Product quality, reduced fuel oil volume, optimized cracking process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

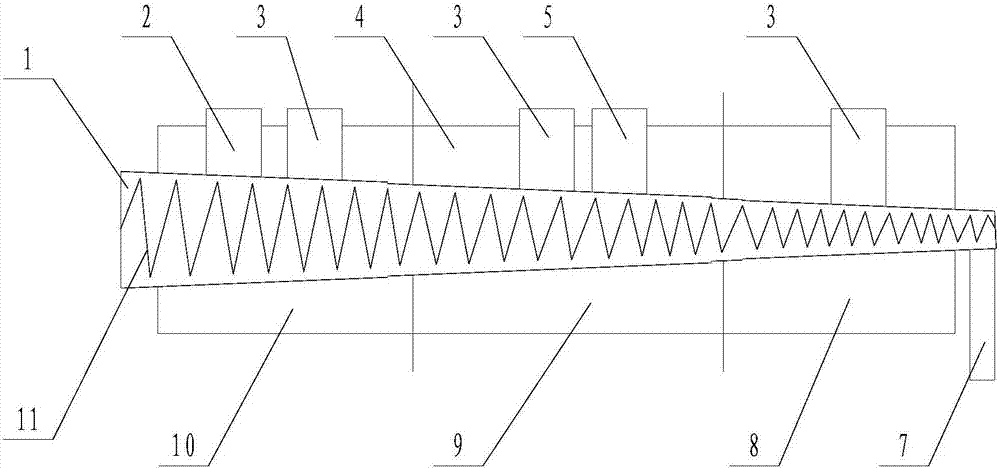

[0029] The device for producing low-ash and low-sulfur carbon black by pyrolysis of waste tires includes a cracking chamber 1 and an external heating chamber 4, and the cracking chamber 1 includes an initial cracking zone 10, a middle cracking zone 9 and a rear cracking zone 8 , the upper part of the first cracking zone 10 is provided with a raw material inlet 2, and the end of the rear cracking zone 8 is provided with a pyrolysis carbon black outlet 7, and the first cracking zone 10, the middle cracking zone 9 and the rear cracking zone 8 are respectively provided with Cracked gas outlet 3.

Embodiment 2

[0031] The device for producing low-ash and low-sulfur carbon black by pyrolysis of waste tires includes a cracking chamber 1 and an external heating chamber 4, and the cracking chamber 1 includes an initial cracking zone 10, a middle cracking zone 9 and a rear cracking zone 8 , the upper part of the first cracking zone 10 is provided with a raw material inlet 2, and the end of the rear cracking zone 8 is provided with a pyrolysis carbon black outlet 7, and the first cracking zone 10, the middle cracking zone 9 and the rear cracking zone 8 are respectively provided with Cracking gas outlet 3, cracking catalyst inlet 5 is also provided on the upper part of the middle cracking zone 9, and the section diameter of the cracking chamber 1 gradually decreases from the raw material inlet 2 to the cracking carbon black outlet 7.

Embodiment 3

[0033] The device for producing low-ash and low-sulfur carbon black by pyrolysis of waste tires includes a cracking chamber 1 and an external heating chamber 4, and the cracking chamber 1 includes an initial cracking zone 10, a middle cracking zone 9 and a rear cracking zone 8 , the upper part of the first cracking zone 10 is provided with a raw material inlet 2, and the end of the rear cracking zone 8 is provided with a pyrolysis carbon black outlet 7, and the first cracking zone 10, the middle cracking zone 9 and the rear cracking zone 8 are respectively provided with Cracking gas outlet 3, the upper part of the middle section cracking zone 9 is also provided with a cracking catalyst inlet 5, and the section diameter of the cracking chamber 1 is gradually reduced from the raw material inlet 2 to the cracking carbon black outlet 7, and the inside of the cracking chamber 1 is provided with There is a feeding screw 11, and the pitch of the feeding screw 11 gradually decreases fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com