Automatic chain belt conveyor

A conveyor and chain belt technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of inaccurate stop position of the transmission belt, unadjustable transmission speed of the transmission belt, and insufficient running of the transmission belt products, etc., to achieve control The effect of staying time, preventing product misoperation, and preventing product from being in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

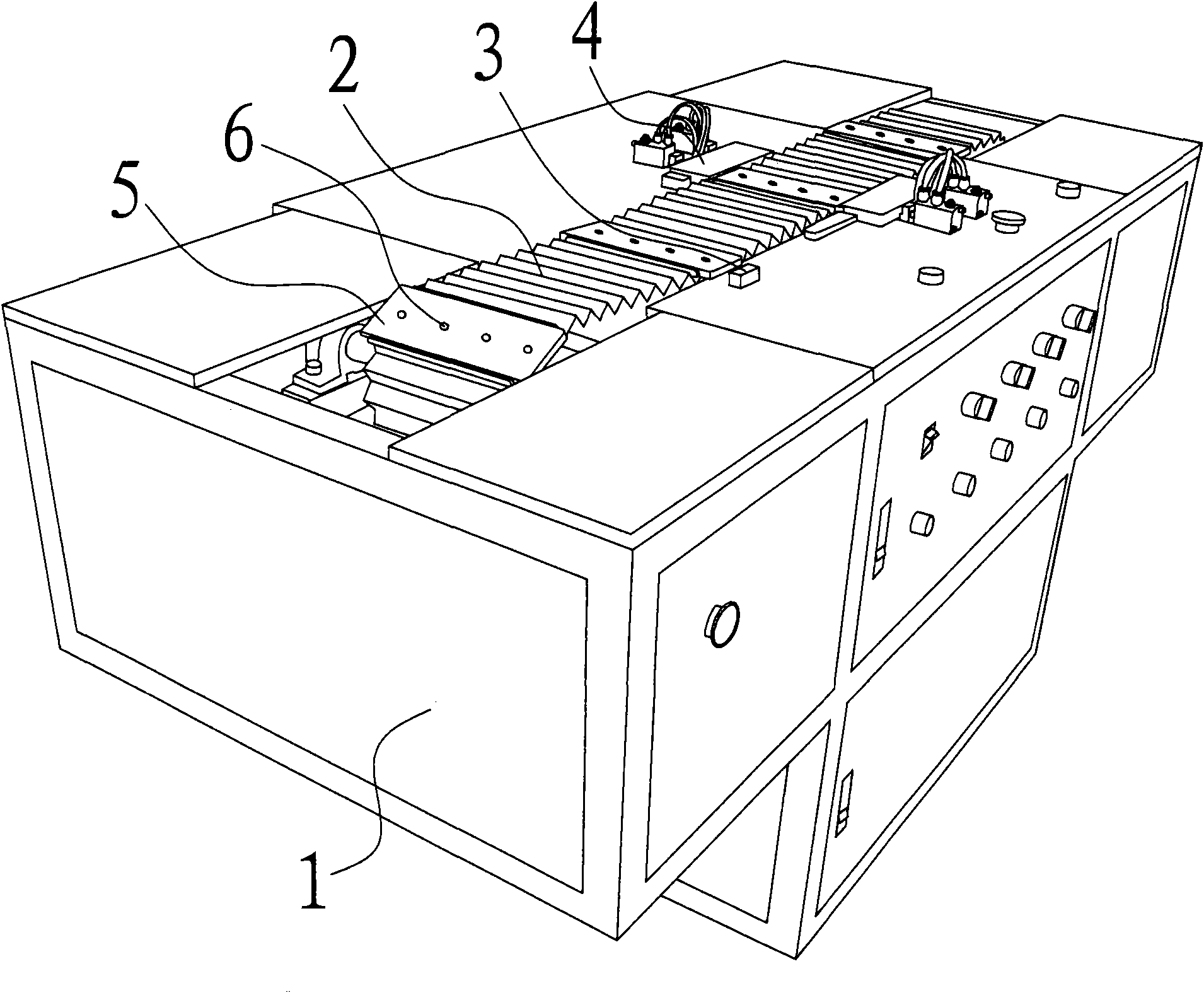

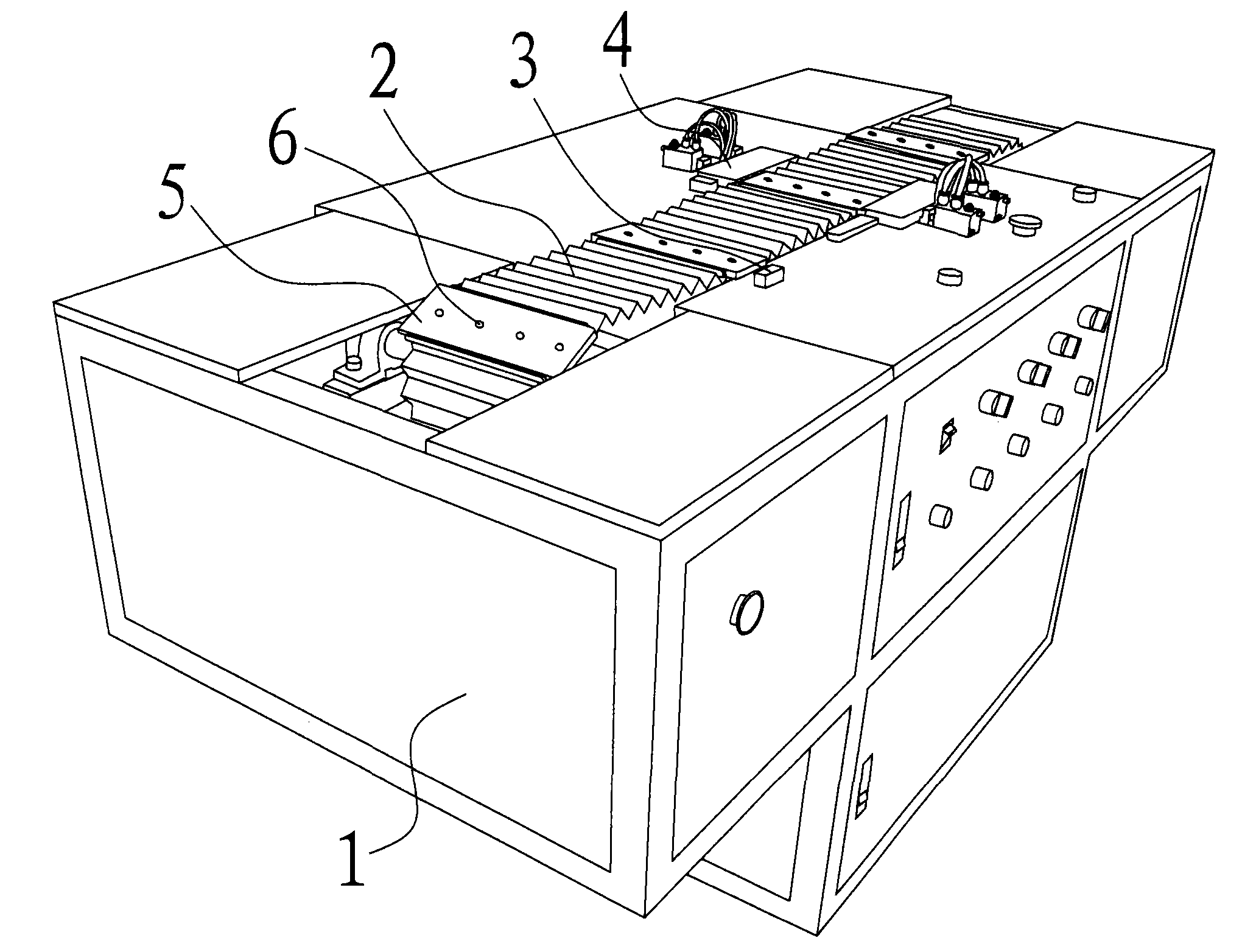

[0012] See figure 1 As shown, the present invention includes: a frame 1, a driving wheel installed on the frame 1, a driven wheel, a speed-regulating motor for driving the driving wheel to rotate, an induction switch 3, a timer, and a control circuit, wherein the speed-regulating motor, the induction switch 3. The timers are respectively connected with the control circuit.

[0013] Specifically: the above-mentioned driving wheel drives the driven wheel to rotate through a transmission belt 2, the driving wheel and the driven wheel are respectively the main sprocket and the driven sprocket, and the transmission belt 2 is a chain belt. Eight supporting plates 5 are installed on the transmission belt 2, and four positioning screw holes 6 are respectively arranged on these supporting plates 5, and various types of clamps or bottom molds can be conveniently installed on the supporting plates 5 through these positioning screw holes 6. .

[0014] Above-mentioned timer can control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com