Assembly line connection machine

A connecting machine and assembly line technology, applied in the field of display screens, can solve the problems that FPC boards are easily rolled into the furnace mouth chain, fall into the same rubber basin, and damage FPC boards, so as to facilitate AOI testing and reduce product scrapping rate, the effect of speeding up the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

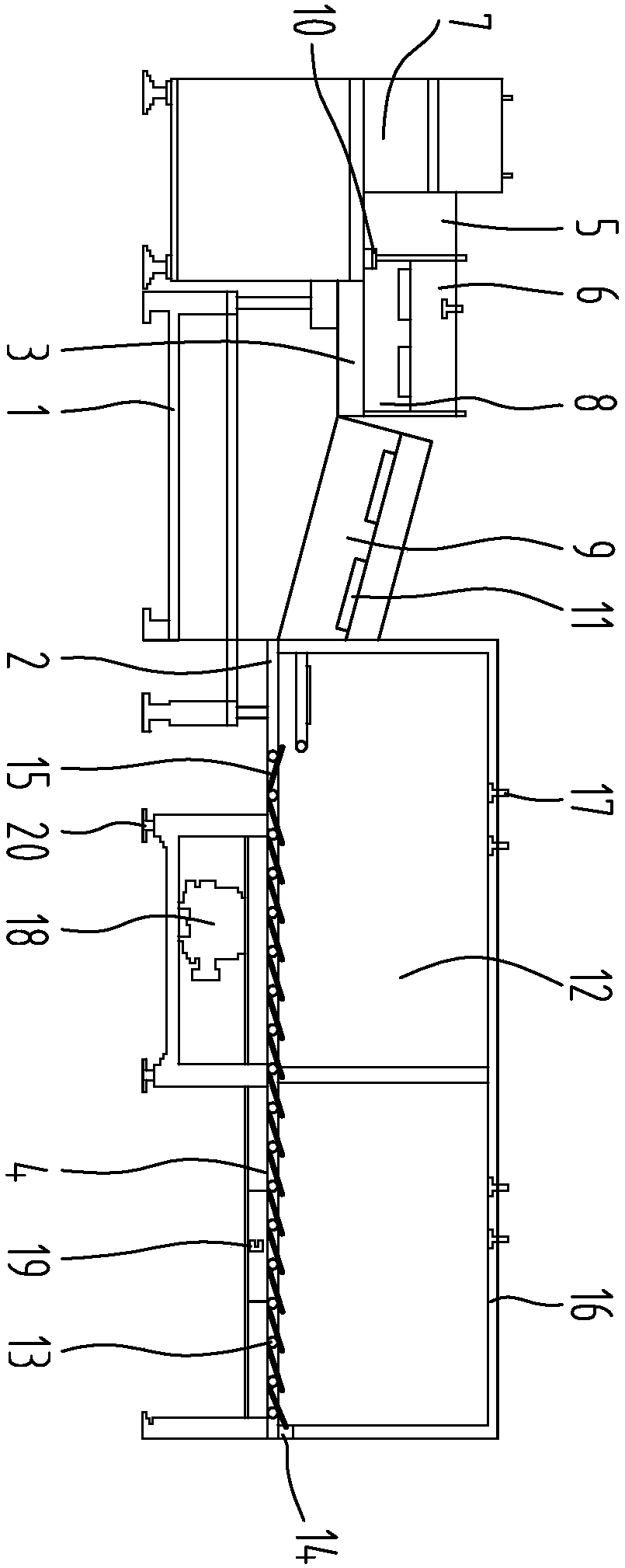

[0019] Such as figure 1 As shown, the present invention provides an assembly line splicing machine, which includes a bracket 1 and a material conveyor belt 2 positioned on the bracket 1, the material conveyor belt 2 sequentially includes a first material conveyor belt 3 and a second material conveyor belt 4, the first The material conveyor belt 3 is a belt transmission. The first material conveyor belt 3 is provided with a material receiving part 5 and a cooling part 6 in sequence. The material receiving part 5 is connected to the outlet 7 of the reflow furnace, and the FPC board coming out of the outlet 7 of the reflow furnace 15 is directly transferred to the material receiving part 5, the cooling part 6 includes the first cooling group 8 and the second cooling group 9, and a height-adjustable horizontal bar is provided at the entrance of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com