Combination cable laying device

A combined cable laying technology, which is applied in cable laying equipment, transportation and packaging, and delivery of filamentous materials, etc., can solve the problems of difficult construction safety at high places, unfavorable full automation of cable laying, and more manpower consumption. Achieve the effects of improving laying efficiency, increasing operation safety and improving conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

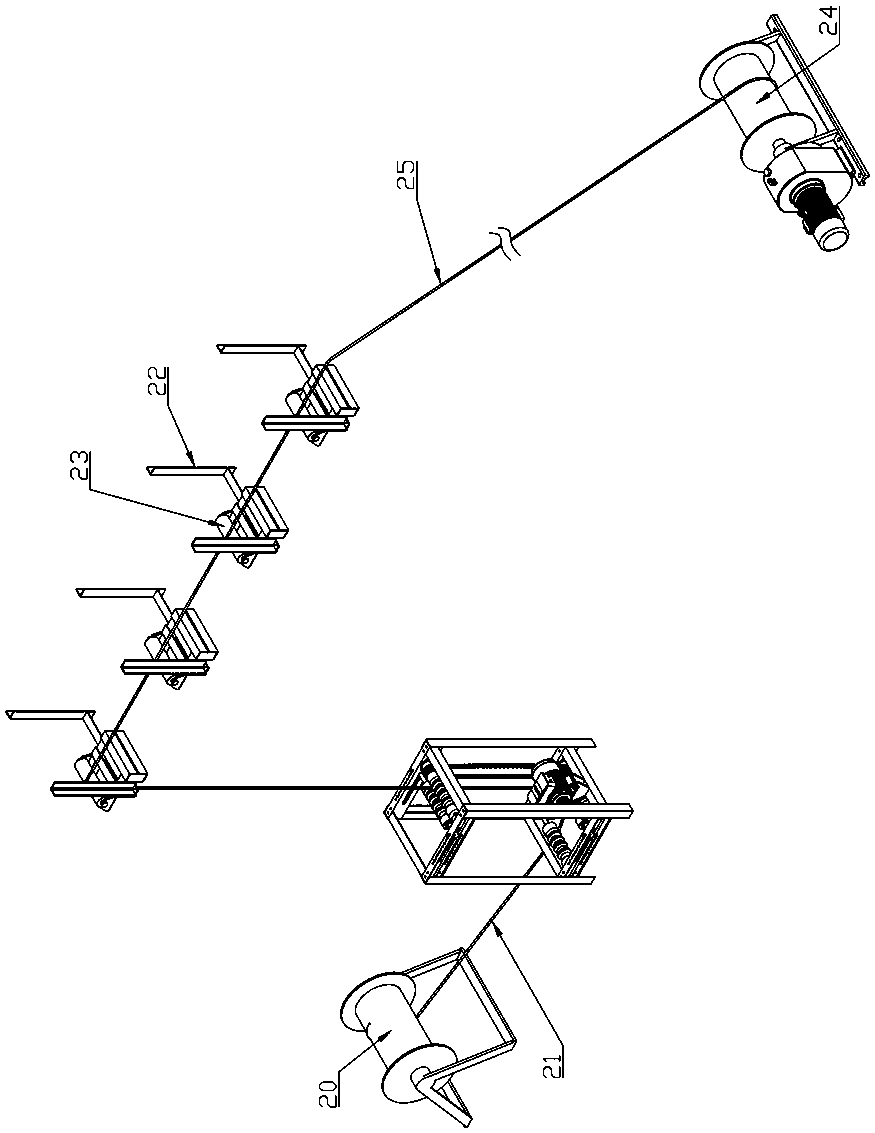

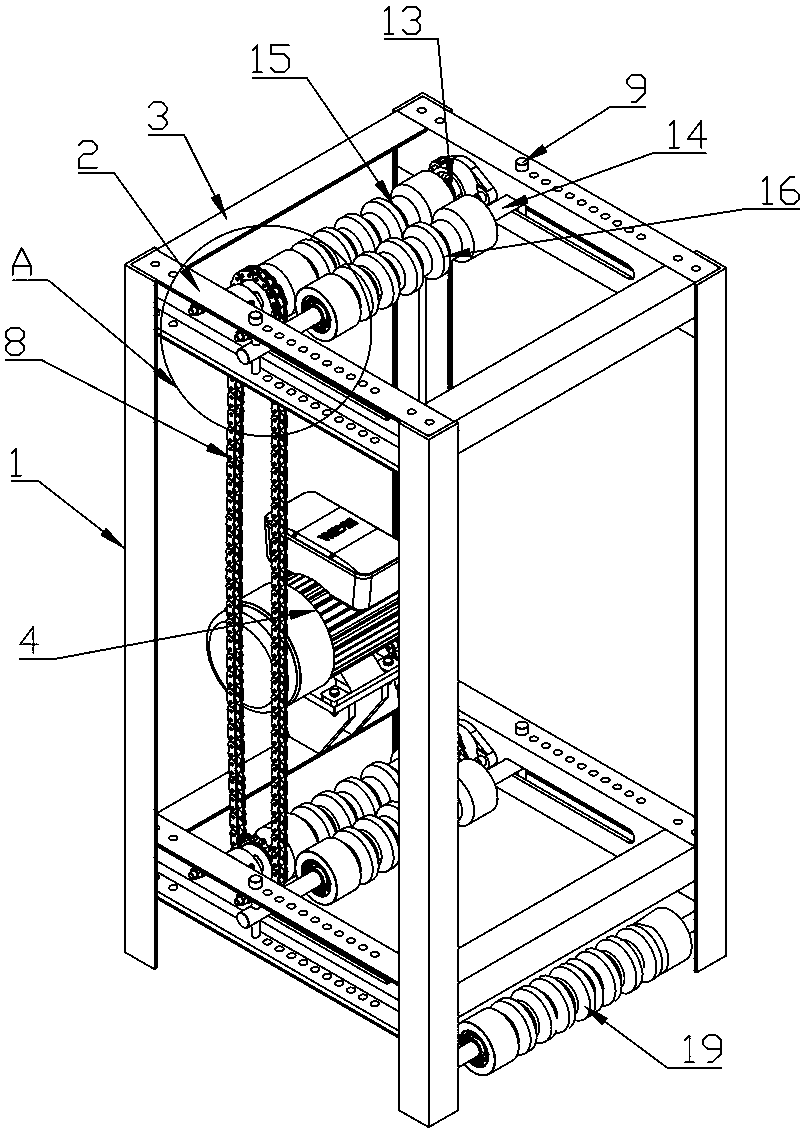

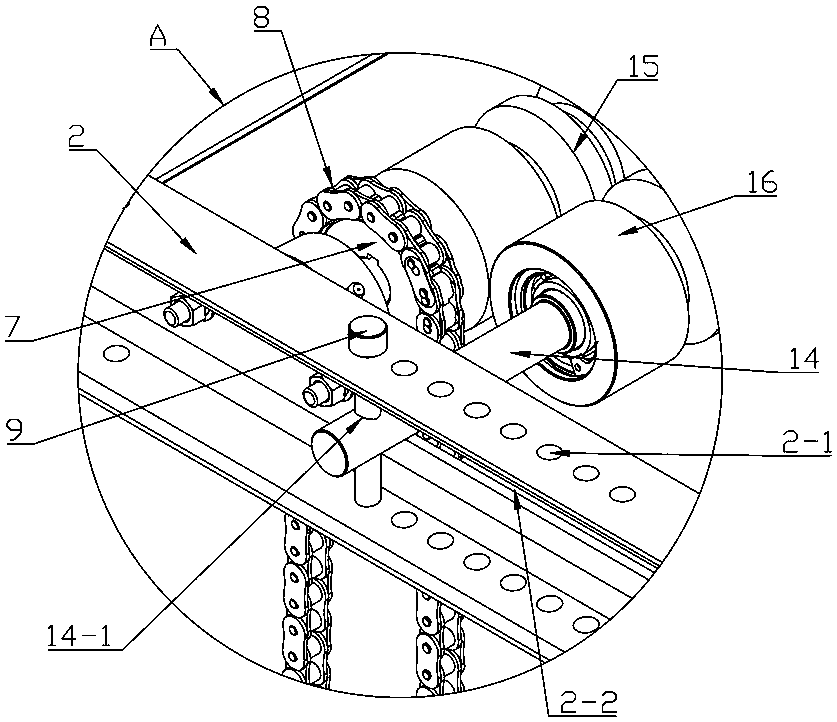

[0031] like figure 1 A combined cable laying and laying device is shown, which includes:

[0032] Traction device, described traction device is winch 24;

[0033] The rolling device includes a support 22 and a roller 23 arranged on the support 22 . The bracket 22 is provided with two arc-shaped grooves 22-1, the two ends of the rotating shaft of the roller 23 are arranged in the arc-shaped groove 22-1, and the rotating shaft ends of the roller 23 are fixedly provided with stoppers. Block 23-1, the distance between the inner surfaces of the two blocks 23-1 is adapted to the distance between the outer end surfaces of the two arc-shaped grooves 22-1. The roller 23 in the rolling device is clamped on the support 22. After the cable 21 is laid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com