A processing equipment for plastic chopsticks

A technology for processing equipment and chopsticks, applied in metal processing equipment, metal processing, grinding/polishing equipment, etc., can solve problems such as inability to locate, throwing chopsticks off, or throwing away, production personnel pneumoconiosis, etc., and achieves adjustable conveying speed. , The effect of increasing the running speed and improving the productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

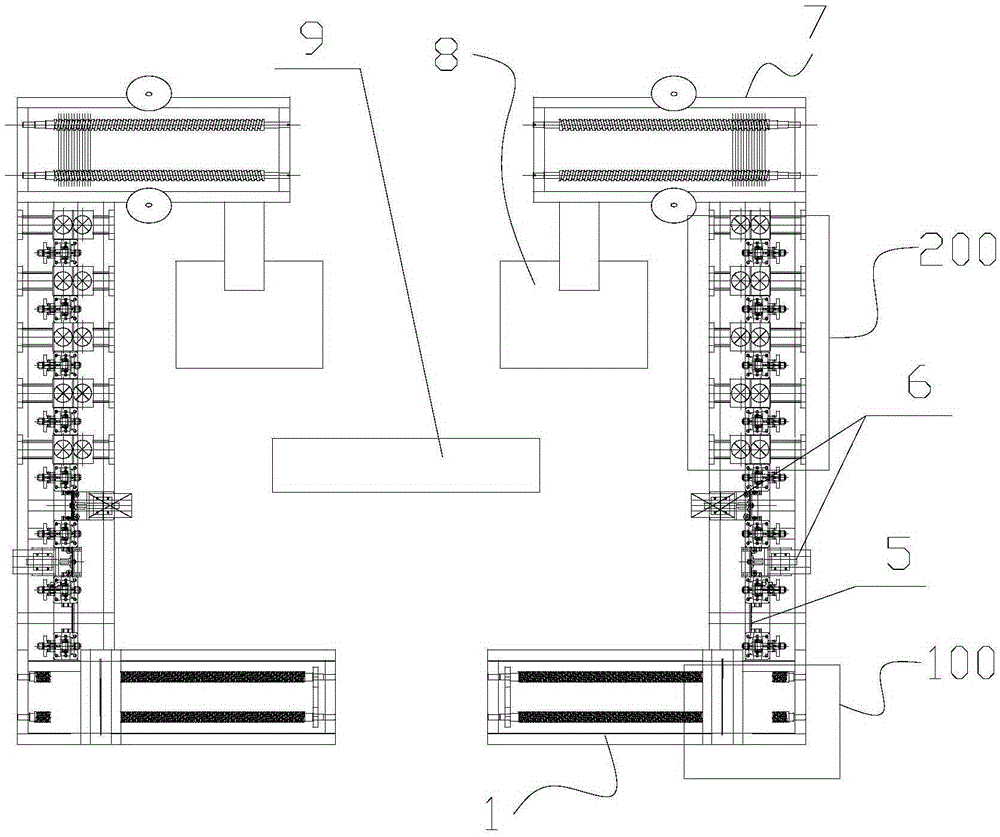

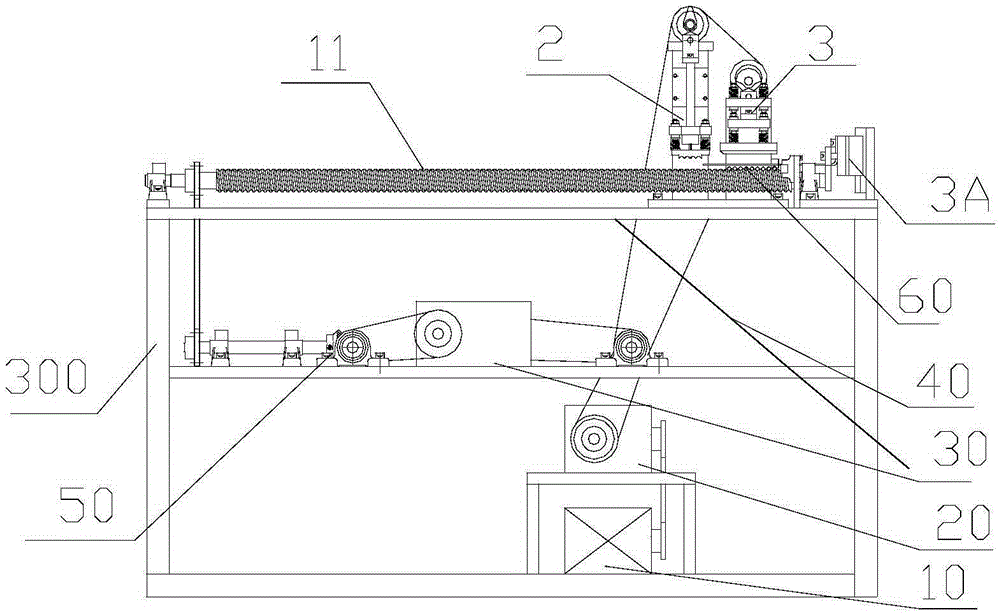

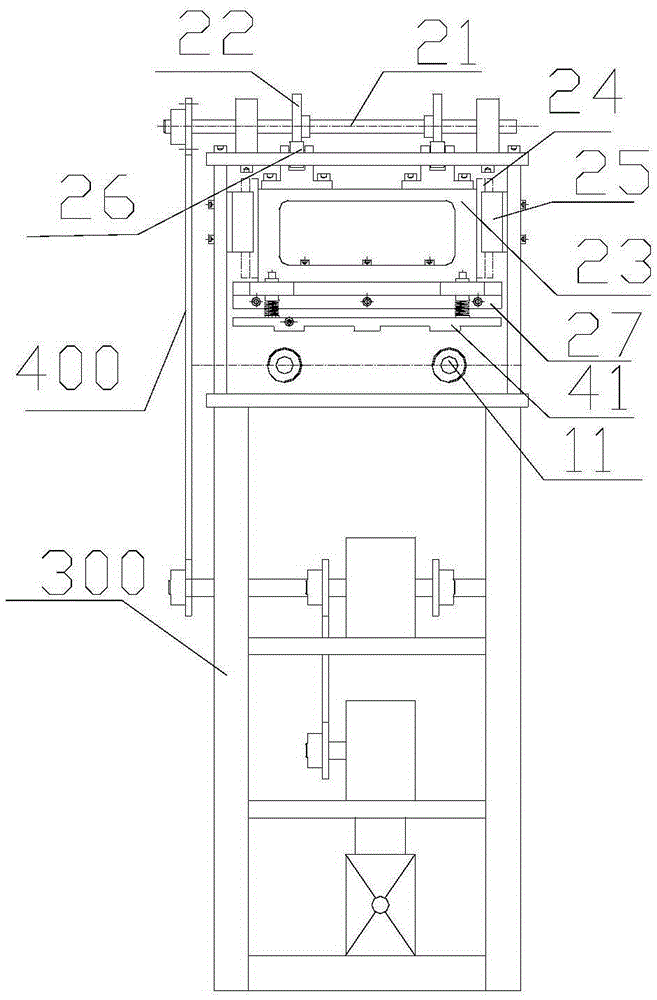

[0036] Such as Figure 1 to Figure 4 Shown, present embodiment provides a kind of processing equipment of plastics or melamine chopsticks, and this processing equipment is to the row shape chopsticks 60 (see Figure 4 ) for processing, the processing equipment includes feeding mechanism 1, slitting mechanism 2, pressing resetter 3, pushing device (pushing device 41 or pushing device 42), transmission line 5, edge grinding device 6, end grinding machine 7 and receiving mechanism 8 (for the convenience of illustration, figure 1 The slitting mechanism 2, the pressure resetter 3 and the pushing device are marked as 100, and other drawings are marked separately). In addition, the present embodiment provides a processing system consisting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com