Aerobic composting device for organic solid waste

An aerobic composting and organic solid technology, applied in the field of composting, can solve the problems of affecting the surrounding environment, producing malodorous gas, and occupying a large area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

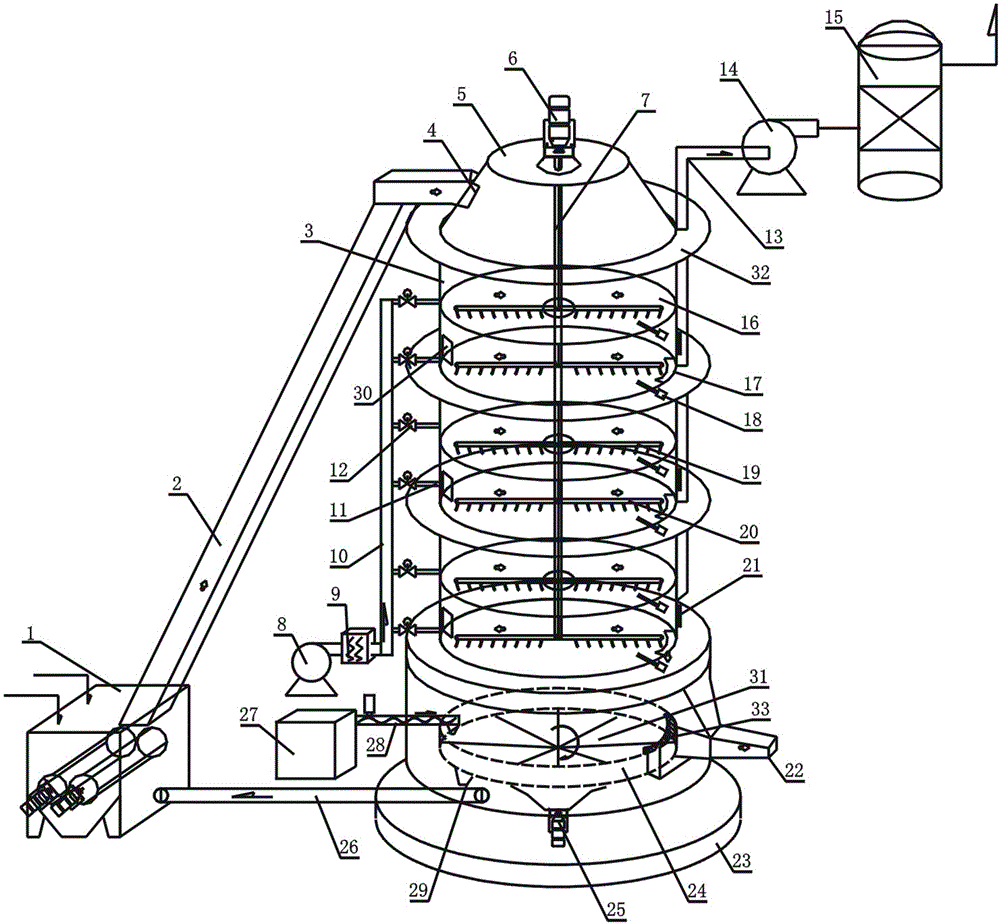

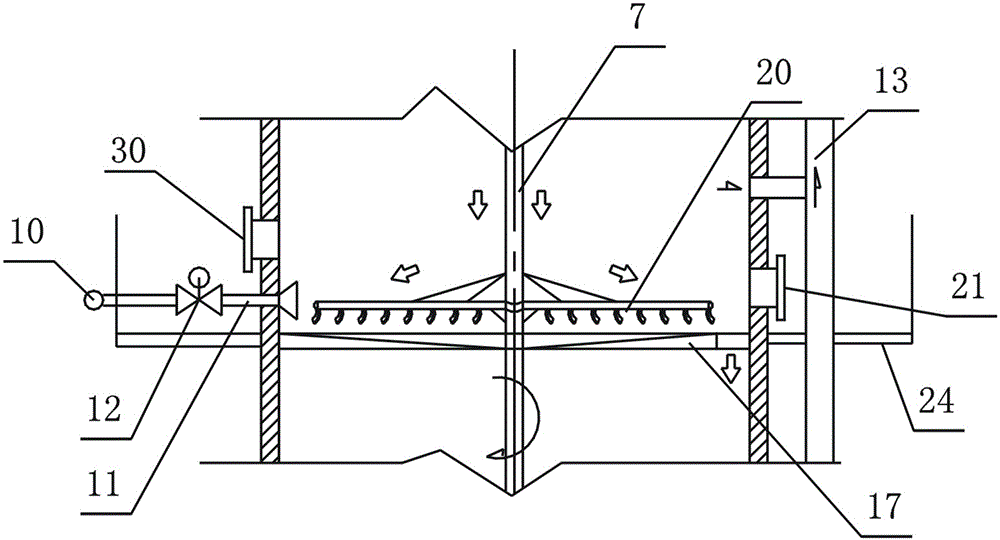

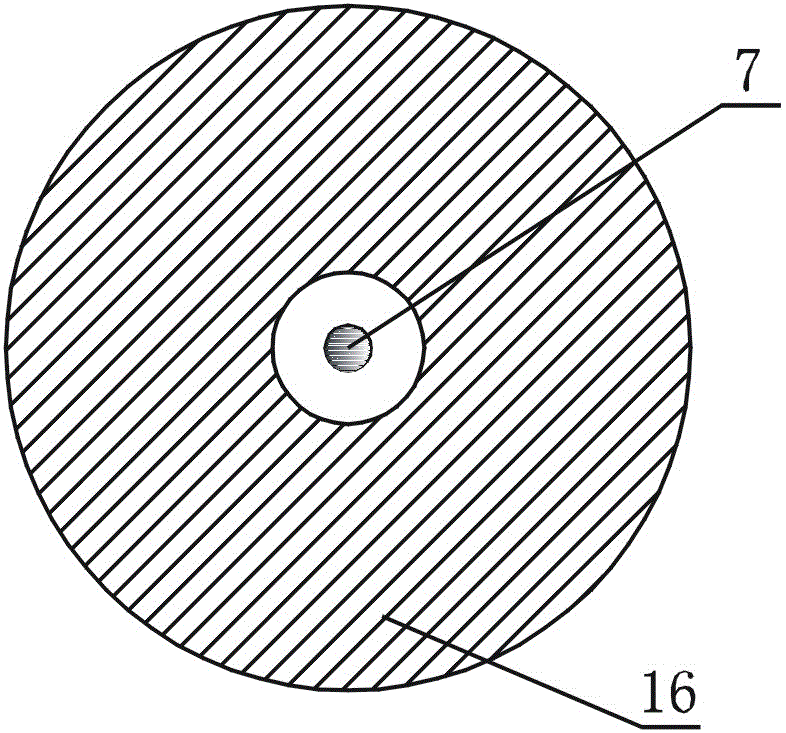

[0034] As shown in Figures 1 to 10, the organic solid waste aerobic composter includes a feed mixer 1, a conveyor 2, a fermentation tower 3, a scraper driving device 6, a blower 8, a heating device 9, an exhaust fan 14, and waste gas treatment Device 15, central discharge tray 16, peripheral discharge tray 17, turntable granulator 24, granulator driving device 25, return conveyor 26, granulating agent adding device 27 and screw conveyor 28, characterized in that : the top of the fermentation tower 3 is provided with a truncated conical cover 5; the turntable granulator 24 is arranged below the fermentation tower 3; The feed port 4 is connected; the center discharge tray 16 is provided with an inward scraper 19, and the peripheral discharge tray 17 is provided with an outward scraper 20, and the inward scraper 19 and the outward scraper 20 are installed on the On the transmission shaft 7; the center of the top of the cover 5 is provided with a scraper driving device 6; in the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com