Non-uniform air distribution interconnected fluidized bed drying device

A fluidized bed drying and non-uniform technology, applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of uneven drying of materials, achieve the elimination of uneven drying or overheating, reduce wear and tear, Optimizing the effect of system energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

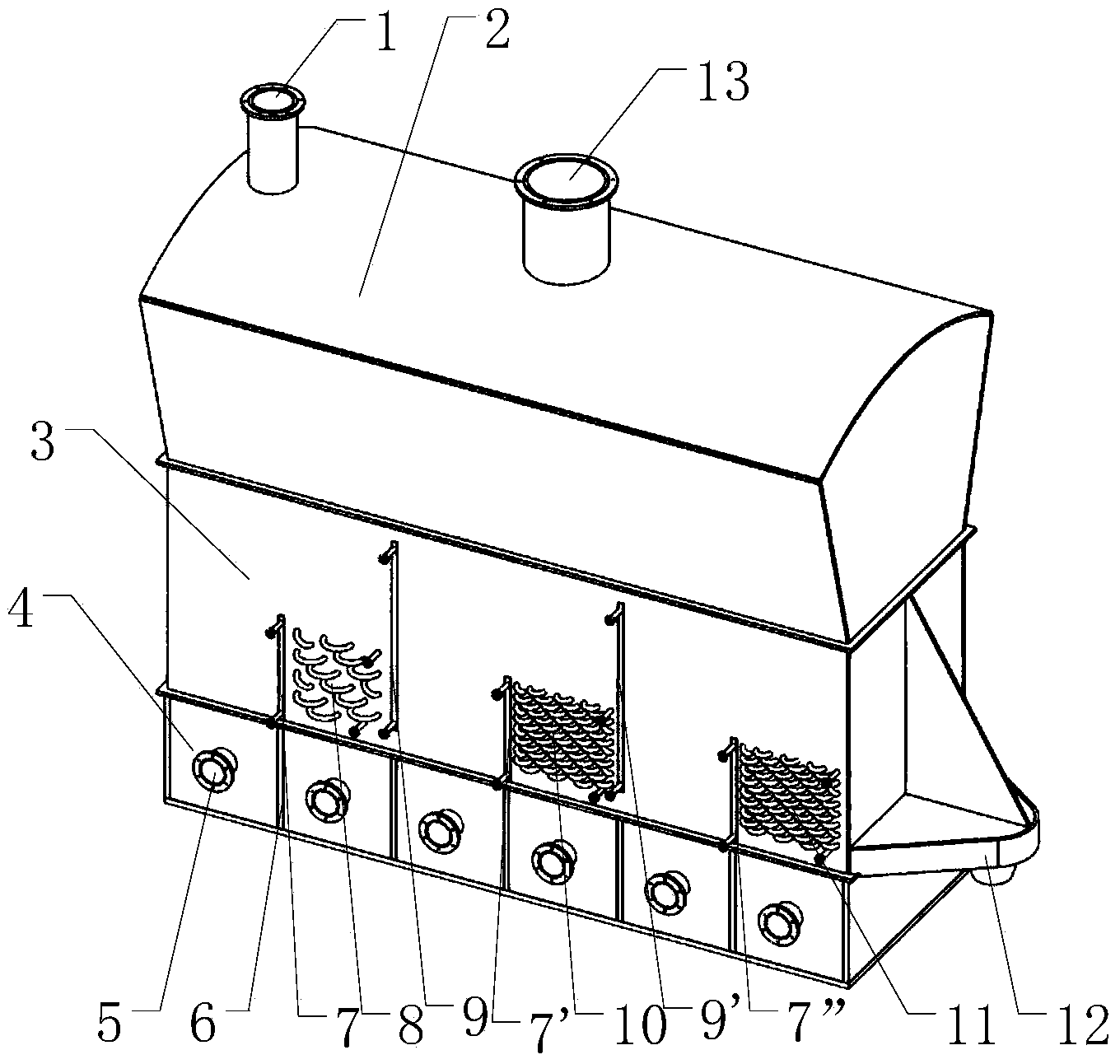

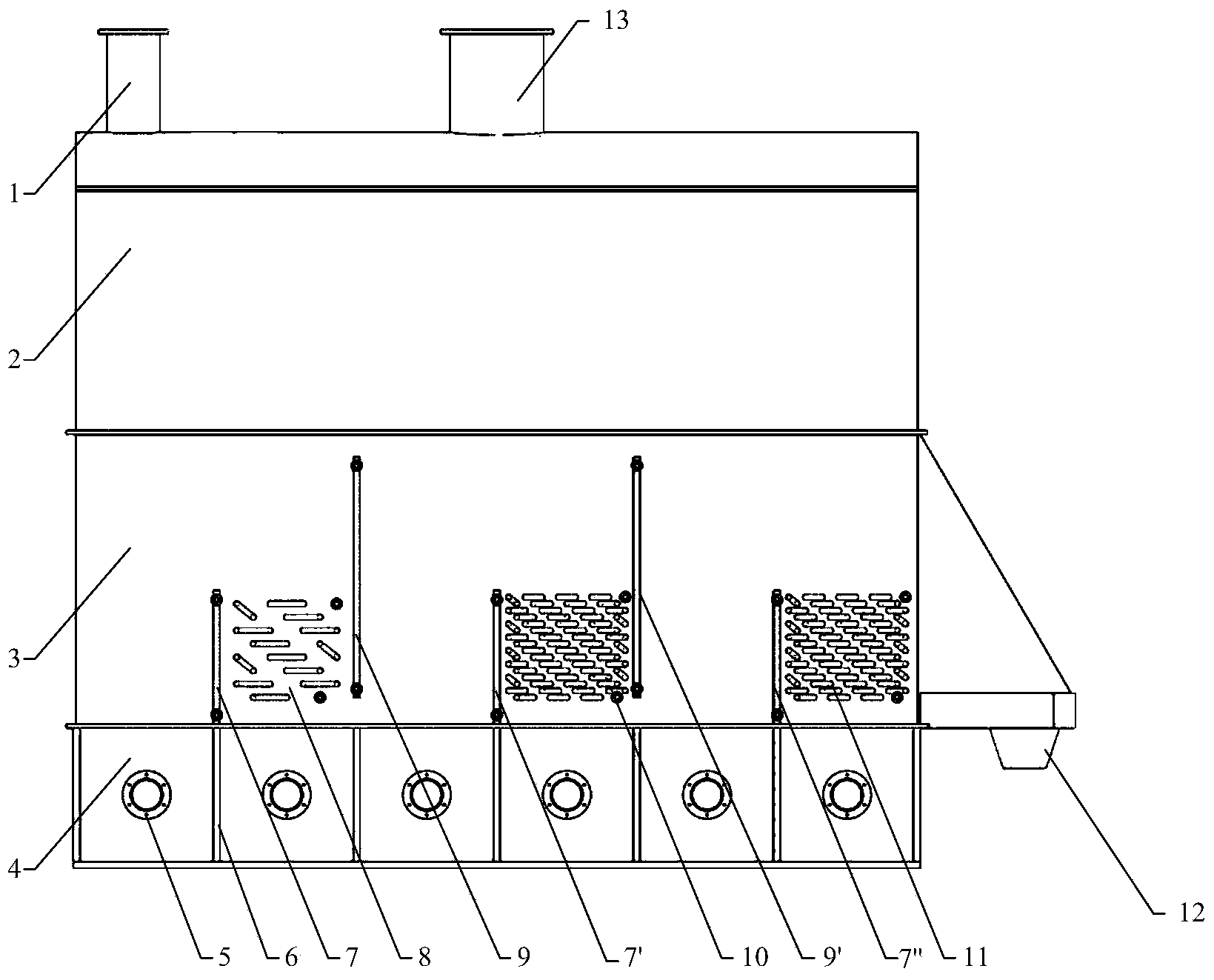

[0026] The invention is a non-uniform air distribution serial fluidized bed drying equipment, the structure is as follows Figure 1-Figure 2 As shown, it consists of separation section 2, fluidization section 3 and air distribution section 4. Among them, the separation section 2 has a feed inlet 1 and an air outlet 13, and its function is to feed and discharge a small amount of moisture with a small amount of dried material; the air distribution section 4 is provided with an air inlet 5 and a partition 6, and its function is to The material to be dried provides momentum and part of the heat and separates the air distribution section 4 to achieve the purpose of independent air supply in different regions; the fluidization section 3 is between the separation section 2 and the air distribution section 4, and its function is to use the heat exchanger and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com