Method for drying polycarbonate

A polycarbonate and drying technology, which is used in drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of high investment cost of centrifugal separator equipment, inability to apply modern fine production, and high equipment investment cost. The residence time can be controlled to avoid the effect of flammable and explosive, and the residence time is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

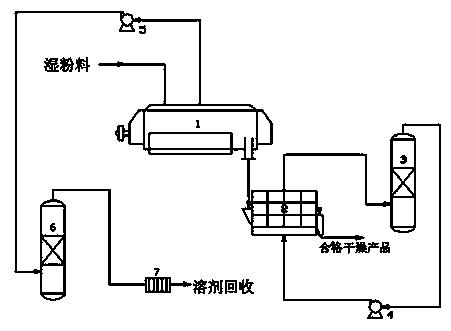

[0022] The previous process generates 500kg / h polycarbonate powder, which contains a certain amount of water and solvent. The polycarbonate wet powder enters the paddle dryer 1 through the star-shaped feeder, and 0.1~0.6Mpa water vapor is introduced into the hollow paddle blade of the paddle dryer 1 and the jacket of the equipment shell, and passes through the paddle dryer. 1 After drying, the water content in the polycarbonate powder is 1-10%, and the methylene chloride content is 100-1000ppm. The powder enters the fluidized bed dryer 2 through the star feeder. The vaporized dichloromethane solvent is transported by the induced draft fan 5 to the solvent washing tower 6 for wet dust removal and cooling after dedusting. The cooled dichloromethane enters the condenser 7 to be condensed and recycled. The polycarbonate powder entering the fluidized bed dryer 2 undergoes a strong mass and heat transfer process so that the final water content is controlled below 1000ppm. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com