Method for preparing nanoscale graphene doped tin antimony oxide thermal insulation dispersion liquid

A technology of tin antimony oxide and graphene, applied in chemical instruments and methods, antimony oxide/antimony hydroxide/antimony oxyacid, nanotechnology, etc., can solve problems such as affecting the quality of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

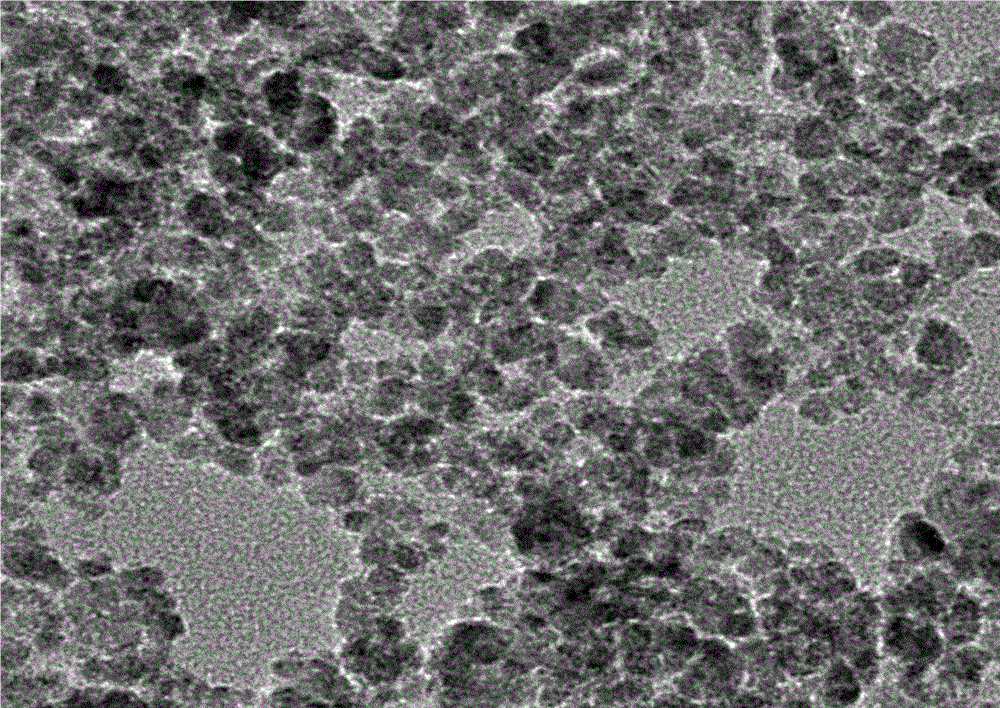

Image

Examples

Embodiment 1

[0020] Example 1: Add 23.45 grams of tin tetrachloride and 4.56 grams of antimony trichloride according to the molar ratio of Sn and Sb 90:20, add 28.01 grams of absolute ethanol and 1.4 grams of 6mol / L HNO 3 And keep stirring until all dissolved; add 32.15 grams of EDTA and 21.14 grams of CA to the solution, then use 3mol / L ammonia solution to adjust the pH value of the solution to 7; heat the solution at 60°C to evaporate excess water and ethanol until a viscous sol is formed. After fully stirring the sol dispersion system, coat it on a special metal plate, so that the coating thickness is below 3mm, and then vacuum-dry the metal plate at 100°C; remove the dry gel from the metal plate, and place it in Ignite in a combustion furnace at 600°C, and after the reaction is completed, fluffy light blue ATO powder can be obtained; ATO powder and nano-scale graphene are dispersed in NMP by ultrasonic and ball milling methods to make a solid content It is an NMP dispersion of 10% ATO...

Embodiment 2

[0021] Example 2: Add 23.45 grams of tin tetrachloride and 4.56 grams of antimony trichloride according to the molar ratio of Sn and Sb 90:20, add 140.04 grams of absolute ethanol and 2.8 grams of 6mol / L HNO 3 And keep stirring until all dissolved; add 48.22 grams of EDTA and 21.14 grams of CA to the solution, then use 3mol / L ammonia solution to adjust the pH value of the solution to 7.5; heat the solution at 65°C to evaporate excess water and ethanol until a viscous sol is formed. After fully stirring the sol dispersion system, coat it on a special metal plate, so that the coating thickness is below 3mm, and then vacuum-dry the metal plate at 100°C; remove the dry gel from the metal plate, and place it in Ignite in a combustion furnace at 650°C, and after the reaction is completed, fluffy light blue ATO powder can be obtained; ATO powder and nano-scale graphene are dispersed in NMP by ultrasonic and ball milling methods respectively to make solid content It is an NMP dispers...

Embodiment 3

[0022] Example 3: Add 23.45 grams of tin tetrachloride and 4.56 grams of antimony trichloride according to the molar ratio of Sn and Sb 90:20, add 280.07 grams of absolute ethanol and 5.6 grams of 6mol / L HNO 3 And keep stirring until all dissolved; add 64.29 grams of EDTA and 21.14 grams of CA to the solution, then use 3mol / L ammonia solution to adjust the pH value of the solution to 8; heat the solution at 70°C to evaporate excess water and ethanol until a viscous sol is formed. After fully stirring the sol dispersion system, coat it on a special metal plate, so that the coating thickness is below 3mm, and then vacuum-dry the metal plate at 100°C; remove the dry gel from the metal plate, and place it in Ignite in a combustion furnace at 700°C, and after the reaction is completed, a fluffy light blue ATO powder can be obtained; the ATO powder and nano-scale graphene are dispersed in NMP by ultrasonic and ball milling methods to make a solid content It is an NMP dispersion liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com