Bullion lead comprehensive treatment method

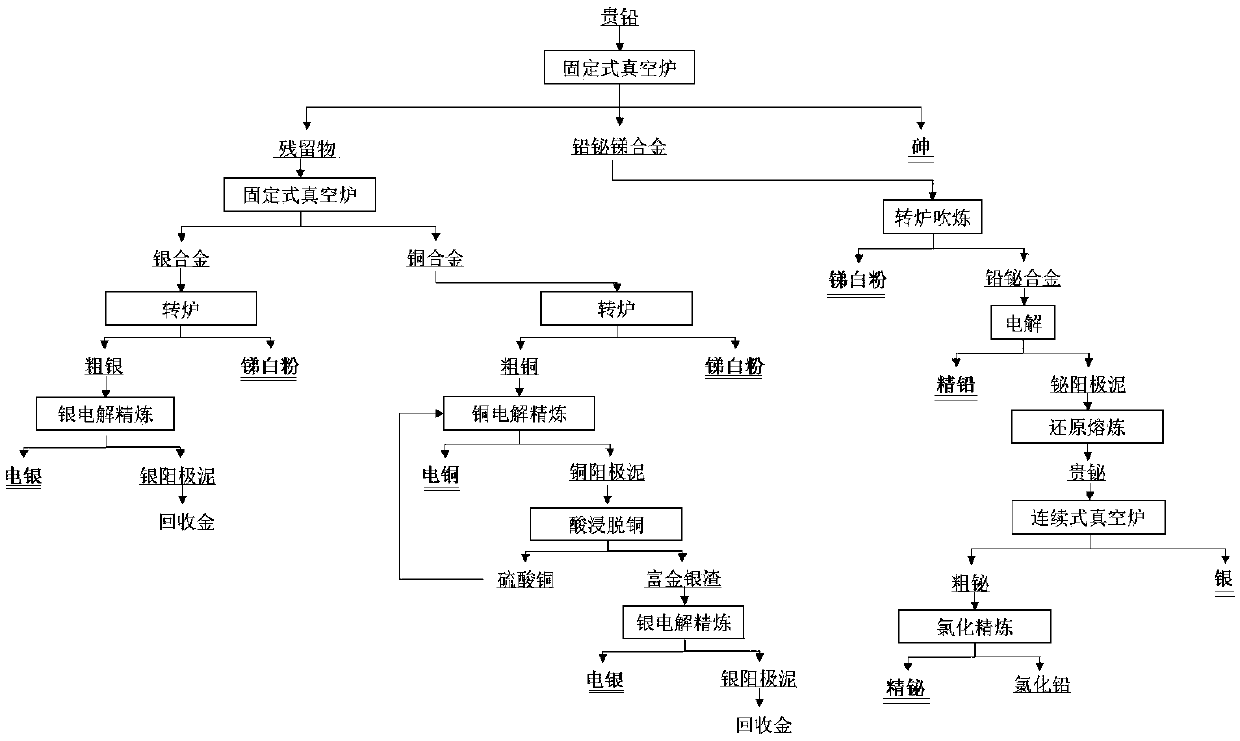

A comprehensive treatment of precious lead technology, applied in chemical instruments and methods, lead halides, antimony compounds, etc., can solve problems such as high environmental pressure, and achieve the effect of simple equipment, short process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 2000kg noble lead materials (Pb 35.14%, Sb14.38%, As 17.21%, Bi 7.60%, Cu 7.54%, Ag 14.93%, Au 18.11g / t, the rest are undetected impurities, the same below, no longer One by one description) placed in a fixed vacuum distillation furnace, cover the vacuum furnace cover to seal the vacuum furnace, use a vacuum pump to evacuate the vacuum in the furnace to 30Pa, and start heating to 800°C when the pressure in the furnace is stable, and carry out the first Stationary vacuum distillation treatment, distillation time 4h, distillation volatiles are condensed and collected in a two-stage condensation method, the first stage is 300-500°C, and the second stage is 25-250°C, of which the lead-bismuth-antimony alloy 920.2 is obtained from the first stage kg (Ag about 0.0154% (154g / t), Cu 0.03%, Sb 6.54%, Pb+Bi 92.09%, As0.91%), the secondary disk obtained 349kg of elemental arsenic (As 95.99%, Pb+Bi+Sb 3.63 %, Cu0.02%, Ag0.0005%); crucible residue 692.2kg (Pb+Bi 0.009%, Sb 32.8%, ...

Embodiment 2

[0087] According to the method for embodiment 1, noble lead alloy is processed. 2000kg precious lead material (component is the same as embodiment 1) is placed in stationary vacuum distillation furnace, covers vacuum furnace lid and vacuum furnace is sealed, with vacuum pump the vacuum in the furnace is drawn to 70Pa, when the pressure in the furnace is stable, start Heating to 900°C, the first stationary vacuum distillation treatment was carried out, the distillation time was 4 hours, the distillation volatiles were condensed and collected by two-stage condensation, and 925.03kg of lead-bismuth-antimony alloy (Ag 203g / t, Cu0.023 %, Sb 7.85%, Pb+Bi 91.09%, As 0.83%), the secondary disc obtained 350kg of elemental arsenic (As 95.7%, Pb+Bi+Sb3.55%, Cu 0.02%, Ag 0.0005%); residual in the crucible 696.2kg (Pb+Bi 0.09%, Sb30.10%, As 0.06%, Cu 21.63%, Ag 42.69%).

[0088]For the lead-antimony-bismuth alloy obtained by the first stationary vacuum distillation, it was first put into ...

Embodiment 3

[0095] According to the method for embodiment 1, noble lead alloy is processed. 2000kg noble lead material (component is the same as embodiment 1) is placed in stationary vacuum distillation furnace, covers vacuum furnace lid and vacuum furnace is sealed, with vacuum pump the vacuum in furnace is drawn to 50Pa, when pressure in furnace is stabilized, start Heating to 850°C, carrying out the first stationary vacuum distillation treatment, the distillation time is 4h, the distillation volatiles are condensed and collected by two-stage condensation, and 931.04kg of lead-bismuth-antimony alloy (Cu 0.21%, Sb8%, Pb +Bi91.19%, As 0.86%, Ag 200g / t), the secondary disc obtained 348.65kg of elemental arsenic (As 96.27%, Pb+Bi+Sb 3.15%, Cu 0.03%, Ag 0.0005%); the residue in the crucible 697.3kg (Pb+Bi0.08%, Sb33.7%, As0.05%, Cu21.48%, Ag42.73%).

[0096] For the lead-antimony-bismuth alloy obtained by stationary vacuum distillation for the first time, first put into the converter blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com