Method for preparing diantimony trioxide nano-particles by mechanochemical modification technology

A technology of antimony trioxide and mechanochemistry, applied in chemical instruments and methods, inorganic chemistry, antimony oxide/antimony hydroxide/antimony oxyacid, etc., can solve the problem of high cost, difficult industrial application, and many factors affecting the preparation process and other issues, to achieve the effect of increasing product added value, easy industrial production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

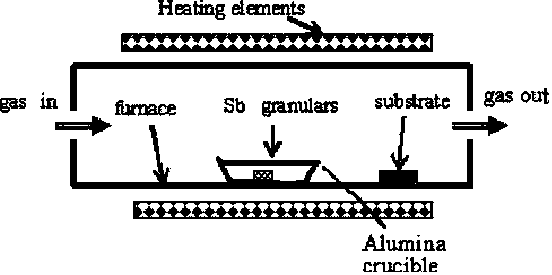

[0066] Example 1 A method for preparing nano antimony trioxide particles by a mechanochemical modification method, comprising the following steps:

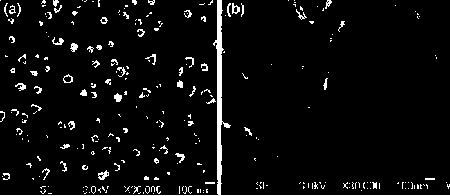

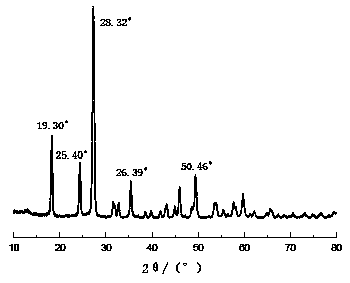

[0067] (1) Put 10g of micron antimony trioxide, 395g of hard alloy small steel balls and 14mL of distilled water into the stainless steel ball milling tank of a planetary high-energy ball mill, and ball mill for 30 hours at a speed of 300 r / min to obtain nano-Sb 2 o 3 Particles (such as Figure 5 shown).

[0068] ⑵nano-Sb 2 o 3 The particles are often washed with warm deionized water, dried at 90°C for 12 hours, and passed through a 100-mesh metal mesh sieve to obtain nano-Sb 2 o 3 samples (such as Figure 6 (b)).

[0069] (3) Add 5g nano-Sb 2 o 3 Put the sample, 195g of hard alloy small steel balls and 9mL of distilled water into the stainless steel ball milling tank of the planetary high-energy ball mill, and adjust the concentration of the solution in the ball milling tank with hydrochloric acid with a concentration of...

Embodiment 2

[0072] Example 2 A method for preparing nano antimony trioxide particles by a mechanochemical modification method, comprising the following steps:

[0073] ⑴Put 10g of micron antimony trioxide, 405g of hard alloy small steel balls and 16mL of distilled water into the stainless steel ball mill tank of planetary high-energy ball mill, and ball mill for 18 hours at a speed of 500 r / min to obtain nano-Sb 2 o 3 Particles (such as Figure 5 shown).

[0074] ⑵nano-Sb 2 o 3 The particles are often washed with warm deionized water, dried at 110°C for 8 hours, and passed through a 100-mesh metal mesh sieve to obtain nano-Sb 2 o 3 samples (such as Figure 6 (b)).

[0075] (3) Add 5g nano-Sb 2 o 3Put the sample, 205g of hard alloy small steel balls and 11mL of distilled water into the stainless steel ball milling tank of the planetary high-energy ball mill, and adjust the concentration of the solution in the ball milling tank with hydrochloric acid with a concentration of 0.01N o...

Embodiment 3

[0078] Example 3 A method for preparing nanometer antimony trioxide particles by mechanochemical modification, comprising the following steps:

[0079] ⑴Put 10g of micron antimony trioxide, 400g of hard alloy small steel balls and 15mL of distilled water into a stainless steel ball mill tank of a planetary high-energy ball mill, and ball mill for 24 hours at a speed of 400 r / min to obtain nano-Sb 2 o 3 Particles (such as Figure 5 shown).

[0080] ⑵nano-Sb 2 o 3 The particles are often washed with warm deionized water, dried at 100°C for 10 hours, and passed through a 100-mesh metal mesh sieve to obtain nano-Sb 2 o 3 samples (such as Figure 6 (b)).

[0081] (3) Add 5g nano-Sb 2 o 3 Put the sample, 200g of hard alloy small steel balls and 10mL of distilled water into the stainless steel ball milling jar of planetary high-energy ball mill, and adjust the concentration of the solution in the ball milling jar with hydrochloric acid with a concentration of 0.01N or sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com