Preparation method of ultrafine high-purity antimony-doped tin oxide nanometer powder

An antimony-doped tin oxide and nano-powder technology, applied in tin oxide, chemical instruments and methods, antimony compounds, etc., can solve the problems of inability to meet the preparation of small particles of ATO, impure ATO materials, and asynchronous hydrolysis, etc. Small diameter, easy to disperse, to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

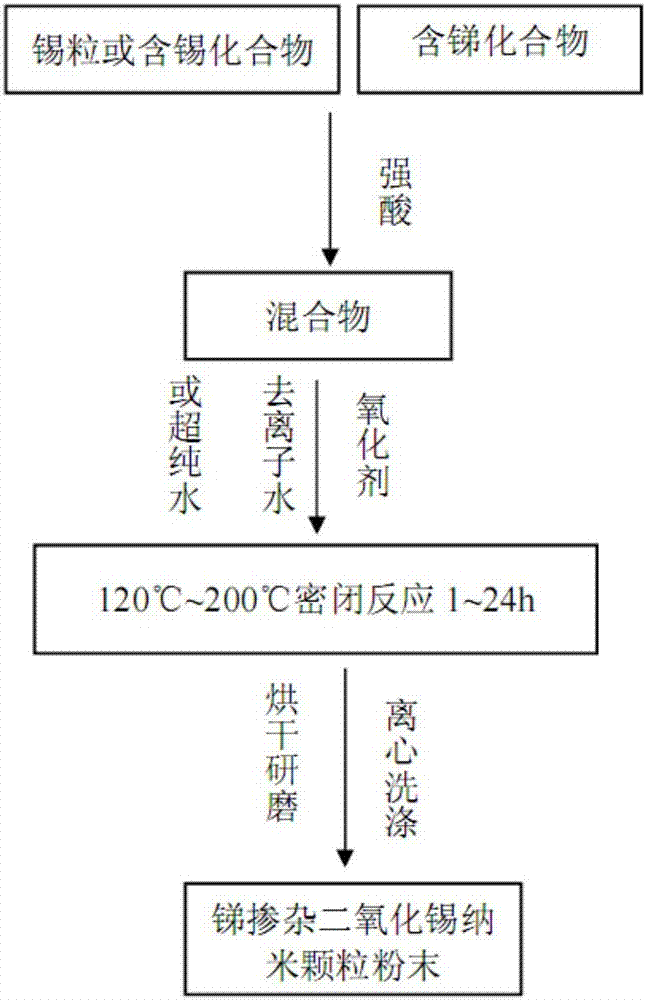

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of superfine high-purity antimony-doped tin oxide nanopowder comprises the following steps: taking tin grains and antimony trioxide, adding concentrated sulfuric acid, adding hydrogen peroxide and deionized water, and then transferring to a closed reaction kettle, 120 ℃ for 1 h, cooled to room temperature, centrifuged and washed until neutral, dried, and ground to obtain antimony-doped tin dioxide nanoparticle powder.

[0027] Take 1 gram of tin particles and 0.29 grams of antimony trioxide (the mass ratio of tin particles to antimony trioxide is 3.4:1). Add 5 mL of concentrated sulfuric acid with a mass fraction of 98%. Add 5 g of hydrogen peroxide and 15 mL of deionized water.

Embodiment 2

[0029] The preparation method of the superfine high-purity antimony-doped tin oxide nano-powder comprises the following steps: taking tin sulfate and antimony pentoxide, adding strong acid, adding peracetic acid and ultrapure water, and transferring them to a hydrothermal reaction kettle for 200 After reacting at ℃ for 24 hours, cooling to room temperature, centrifugal washing to neutrality, drying, and grinding to obtain antimony-doped tin dioxide nanoparticle powder.

[0030] Take 1 gram of tin sulfate; the mass ratio of tin sulfate to antimony pentoxide is 158:1. Taking tin sulfate as a benchmark, add 50 mL of concentrated sulfuric acid with a mass fraction of 98% per 1 gram of tin sulfate. Based on tin sulfate, add 10g of peracetic acid and 30mL of ultrapure water to every 1g of tin sulfate.

Embodiment 3

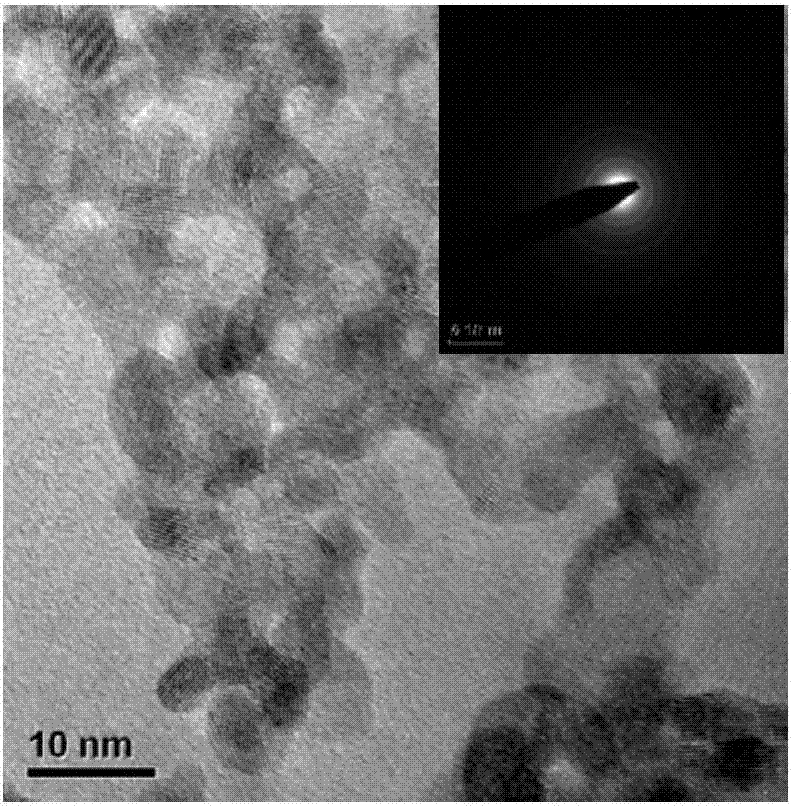

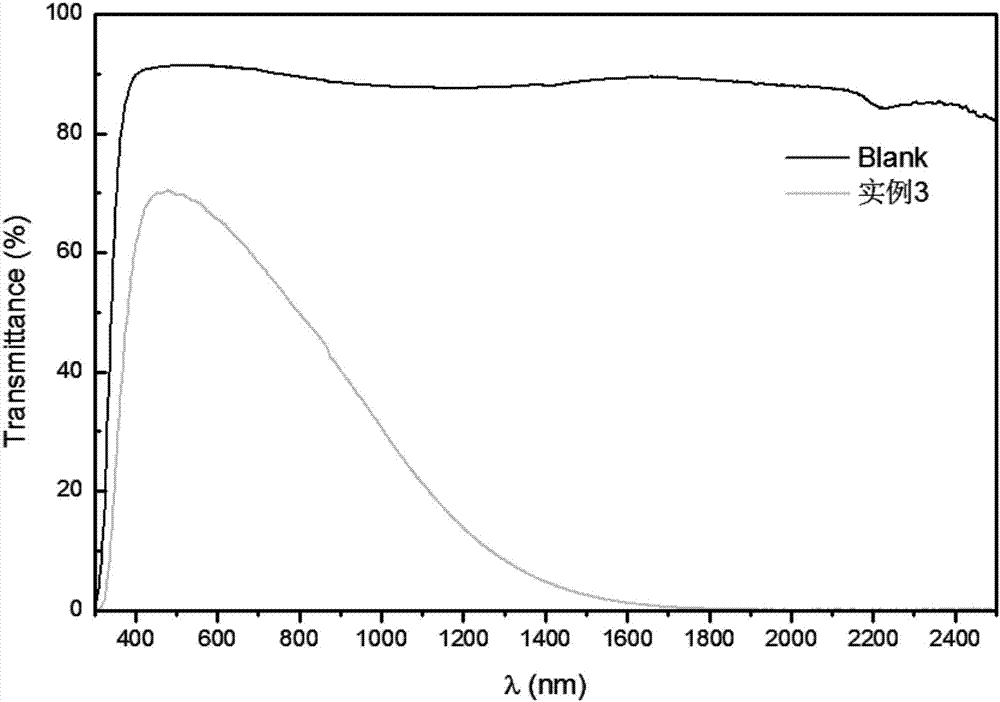

[0032] The preparation method of superfine high-purity antimony-doped tin oxide nanopowder comprises the following steps: taking stannous sulfate and antimony sulfate, adding concentrated sulfuric acid, adding ammonium persulfate and deionized water, and then transferring them to a hydrothermal reaction kettle, 180 After reacting at ℃ for 20 hours, cooling to room temperature, centrifugal washing to neutrality, drying, and grinding to obtain antimony-doped tin dioxide nanoparticle powder.

[0033]Take 10 grams of stannous sulfate, the mass ratio of stannous sulfate to antimony sulfate is 10:1. Taking stannous sulfate as a benchmark, add 25 mL of concentrated sulfuric acid with a mass fraction of 98% in every 1 gram of stannous sulfate. Based on stannous sulfate, add 8 g of ammonium persulfate and 20 mL of deionized water to every 1 g of stannous sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com