Easily-dyed porous modified polyester fiber and preparation method thereof

A technology for modifying polyester and fiber, applied in the field of modified polyester fiber, can solve problems such as unfavorable processing, inability to meet polyester production, and small increase in free volume, so as to increase the free volume of space and shorten the dyeing process. The effect of time and diffusion rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of preparation method of dyeable porous modified polyester fiber, concrete steps are as follows:

[0068] (1) prepare modified polyester;

[0069] (1.1) Preparation of doped modified Sb 2 o 3 ;

[0070] (1.1.1) Mg(NO 3 ) 2 aqueous solution with a concentration of 8 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, the Mg in the mixture 2+ with Sb 3+ The molar ratio is 2:100;

[0071] (1.1.2) Add dropwise ammonia water with a concentration of 2 mol / L until the pH of the mixed solution is 9 to obtain a precipitated product, then wash and dry the precipitated product at a temperature of 105°C for 2.5 hours;

[0072] (1.1.3) The dried product is firstly heated to 400°C and then kept for 2.5 hours, then heated to 900°C and kept for 1.5h, and finally cooled in air and pulverized to obtain a doped modified product with an average particle size of 0.4 microns. Sb 2 o 3 Powder;

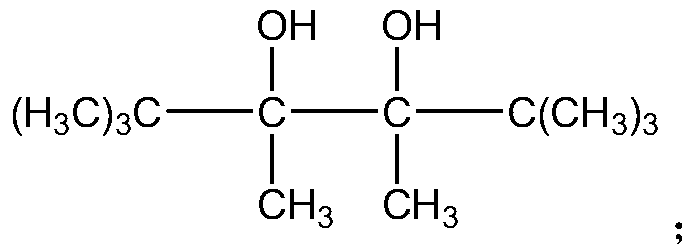

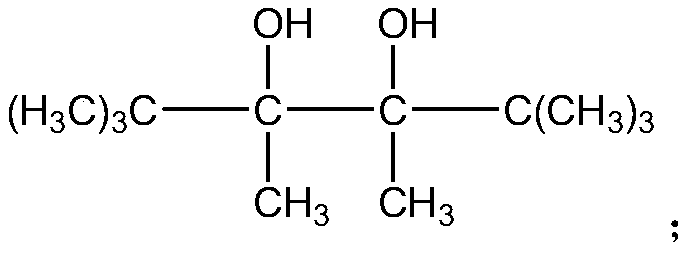

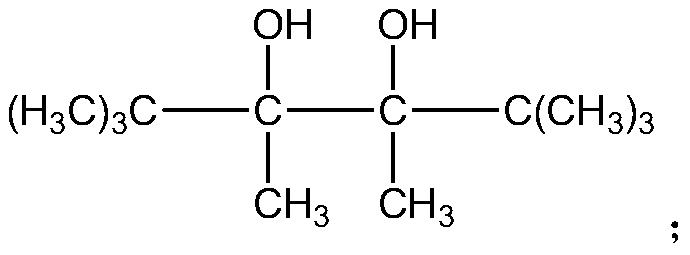

[0073] (1.2) Synthesis of 2,2,3...

Embodiment 2

[0094] A kind of preparation method of dyeable porous modified polyester fiber, concrete steps are as follows:

[0095] (1) prepare modified polyester;

[0096] (1.1) Preparation of doped modified Sb 2 o 3 ;

[0097] (1.1.1) Ca(NO 3 ) 2 Aqueous solution with a concentration of 5 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, the Ca in the mixture 2+ with Sb 3+ The molar ratio is 1:100;

[0098] (1.1.2) Add dropwise ammonia water with a concentration of 2 mol / L until the pH value of the mixed solution is 10 to obtain a precipitated product, and then wash and dry the precipitated product at a temperature of 110° C. for 2 hours;

[0099] (1.1.3) The dried product was first heated to 400°C and then kept for 2 hours, then heated to 900°C and kept for 1 hour, and finally cooled in air and pulverized to obtain doped modified Sb with an average particle size of 0.4 microns 2 o 3 Powder;

[0100] (1.2) Synthesis of 2,2,3,4...

Embodiment 3

[0108] A kind of preparation method of dyeable porous modified polyester fiber, concrete steps are as follows:

[0109] (1) prepare modified polyester;

[0110] (1.1) Preparation of doped modified Sb 2 o 3 ;

[0111] (1.1.1) Ba(NO 3 ) 2 Aqueous solution with a concentration of 10 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, Ba in the mixture 2+ with Sb 3+ The molar ratio is 3:100;

[0112] (1.1.2) Add dropwise ammonia water with a concentration of 2 mol / L until the pH of the mixed solution is 9.5 to obtain a precipitated product, then wash and dry the precipitated product at a temperature of 105°C for 3 hours;

[0113] (1.1.3) The dried product was first heated to 400°C and then kept for 3 hours, then heated to 900°C and kept for 2 hours, and finally cooled in air and pulverized to obtain doped modified Sb with an average particle size of 0.5 microns 2 o 3 Powder;

[0114] (1.2) Synthesis of 2,2,3,4,5,5-hexameth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com