Patents

Literature

30results about How to "Change interaction force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

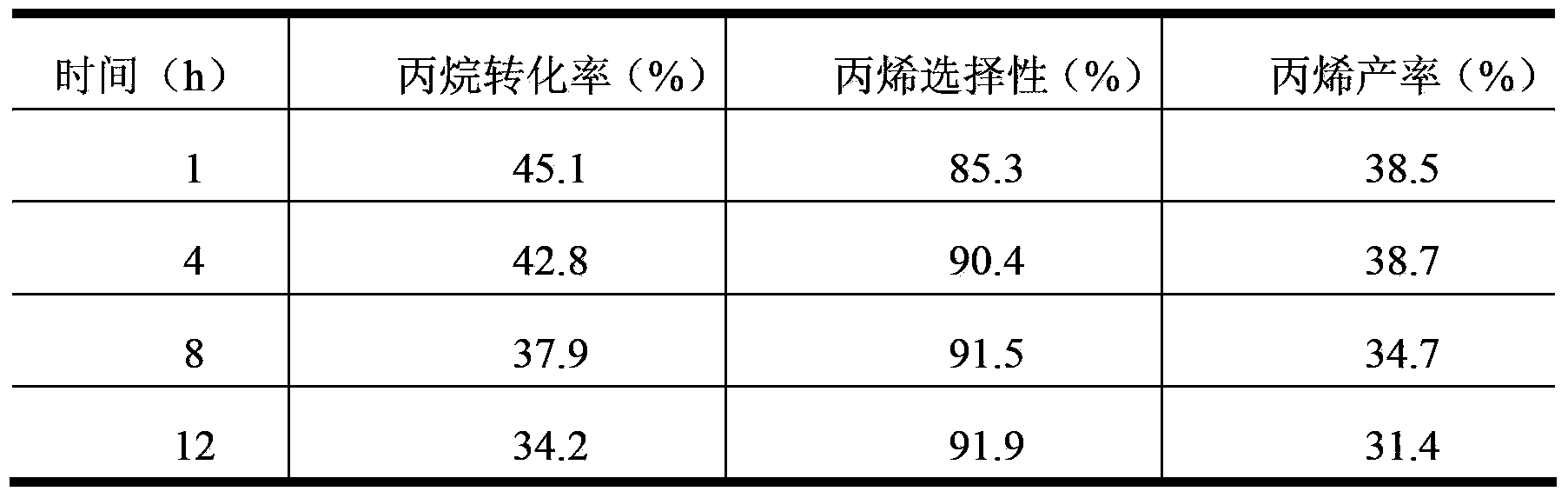

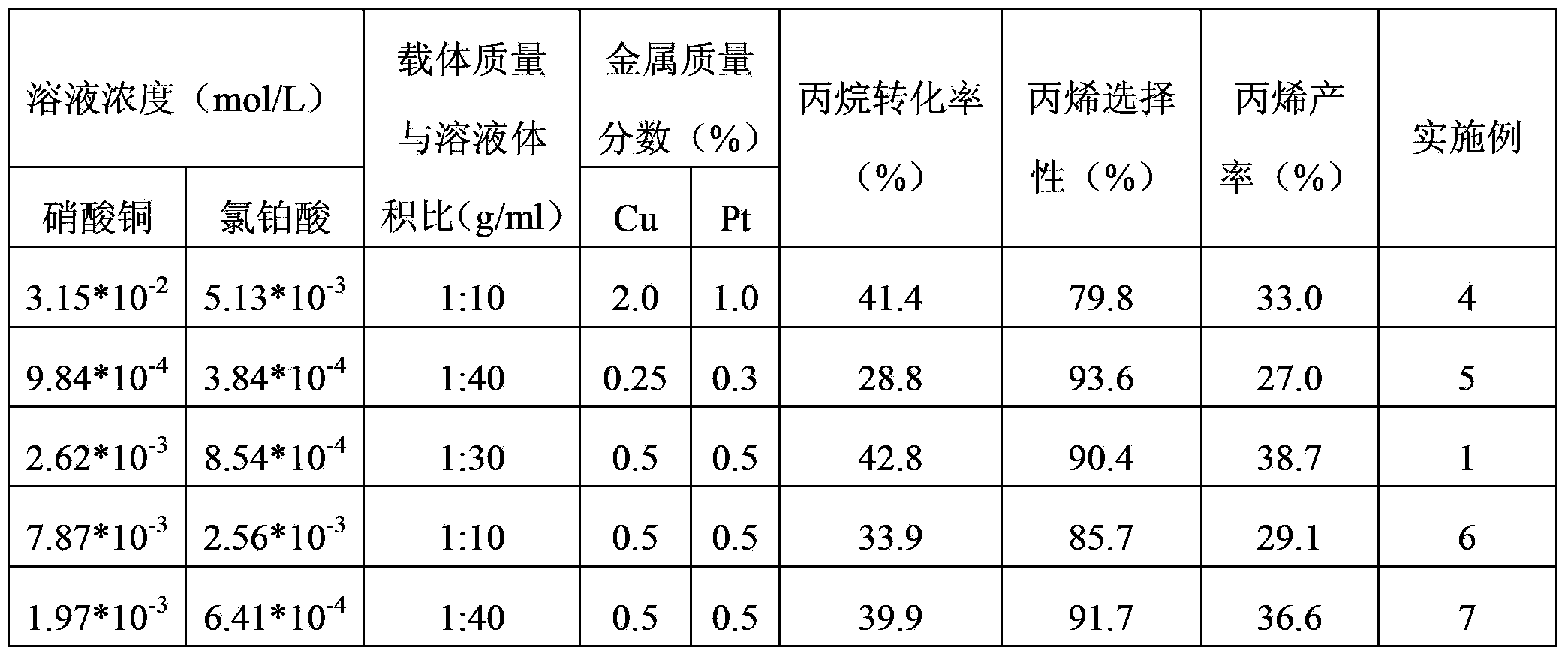

Platinoid bi-component catalyst as well as preparation method and application thereof

InactiveCN103349988AImprove conversion rateEvenly distributedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPlatinumActive component

The invention discloses a platinoid bi-component catalyst as well as a preparation method and application thereof. In the catalyst, gamma-Al203 is taken as a carrier, platinum is taken as an active component, and copper is taken as auxiliary agent. The preparation method includes the following steps: dipping the carrier gamma-Al203 powder in Cu(NO3)2 water solution, removing solvent, drying and roasting, placing the obtained copper-loaded catalyst in H2PtCl6 water solution for dipping, removing solvent, drying and roasting, wherein the platinoid bi-component catalyst can be used in propylene preparation through propane dehydrogenation. According to the invention, copper and platinum in the catalyst interact to change the interaction force between the reactant and the metal surface and between the product and the metal surface, so that better reaction stability at a high temperature in propylene preparation through propane dehydrogenation is guaranteed, the dimethylmethane conversion ratio is higher, the propylene selectivity is excellent; different components of the catalyst can be dipped through the step-by-step dipping method, contents of the components can be controlled easily, and the repeatability is excellent.

Owner:TIANJIN UNIV

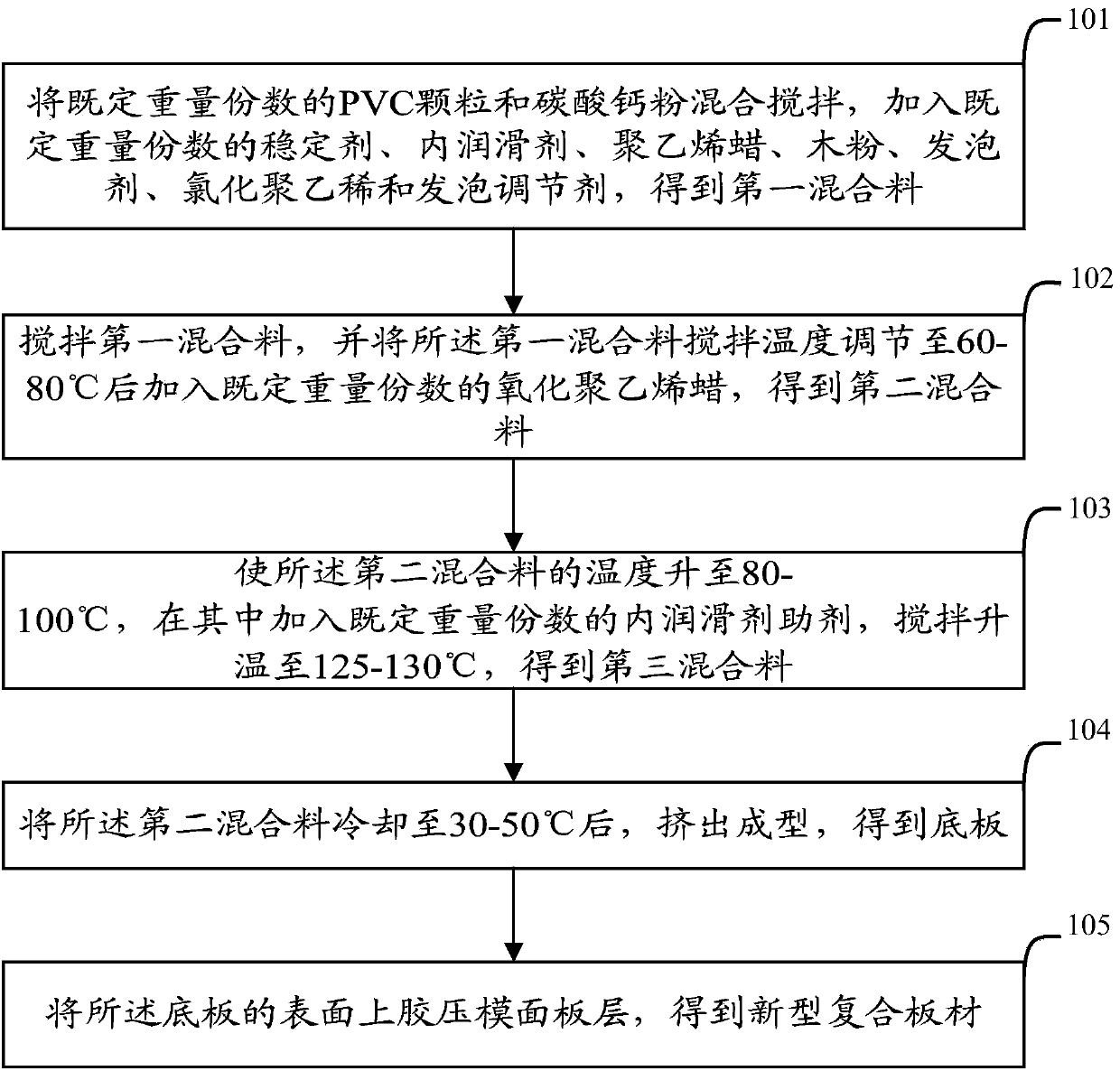

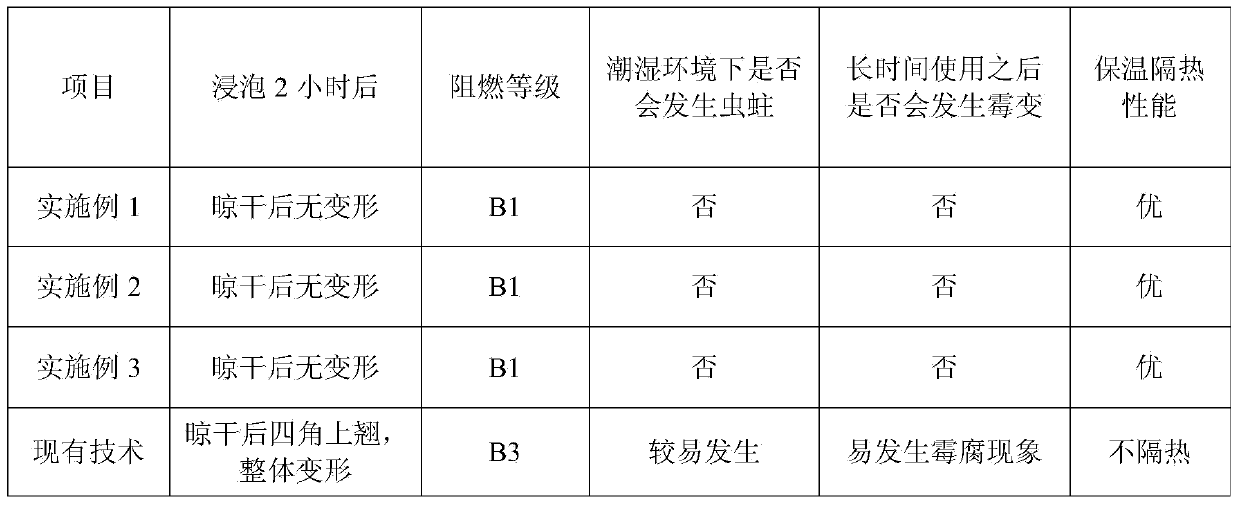

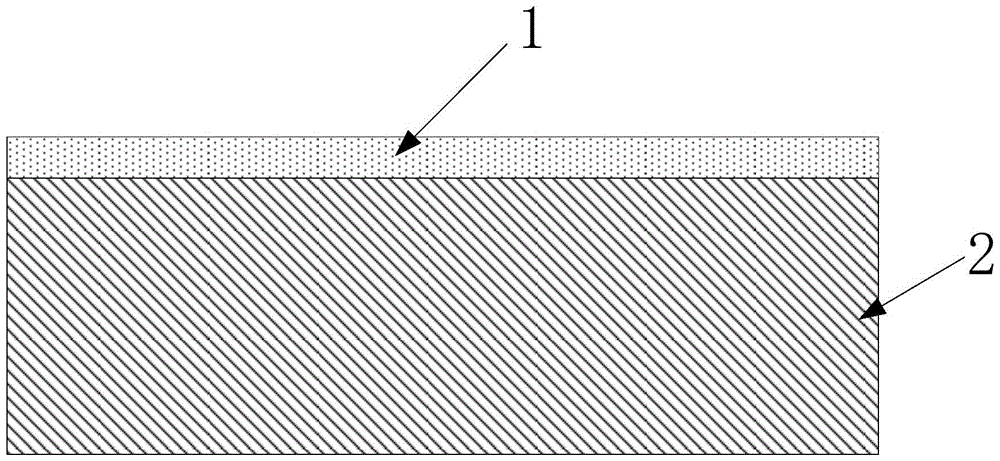

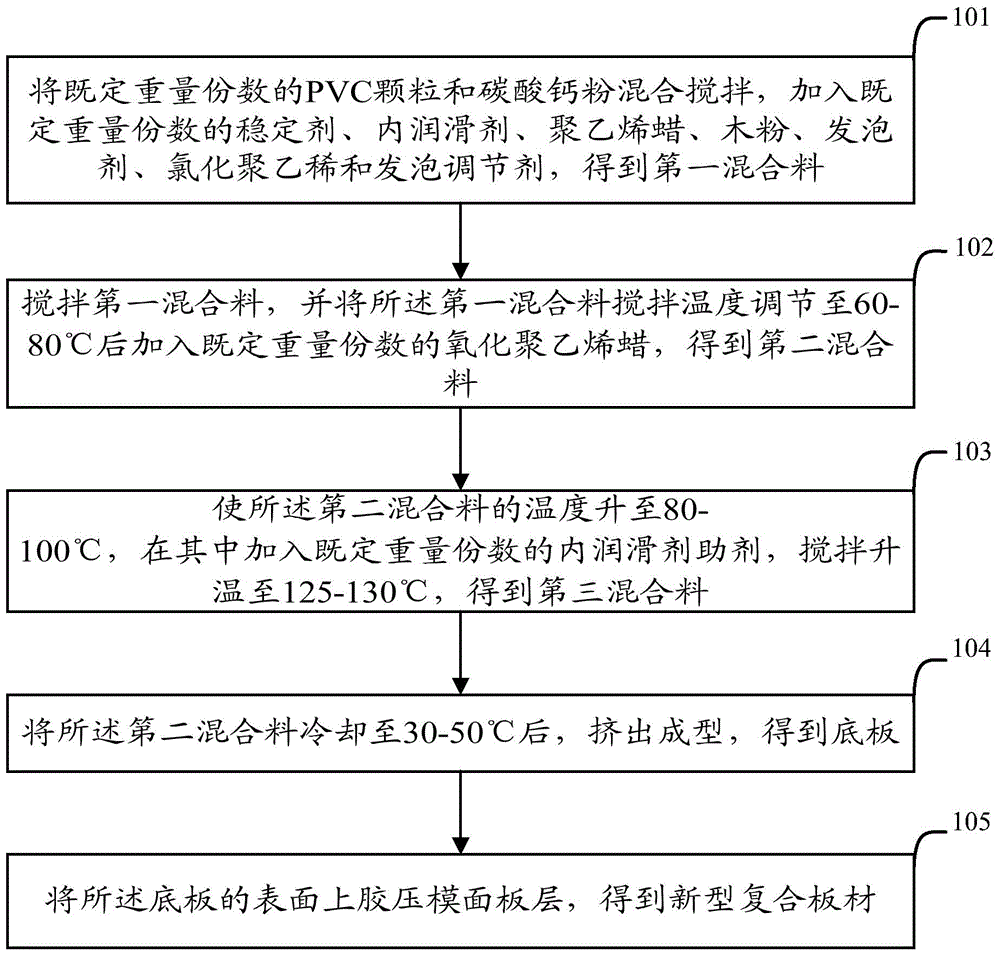

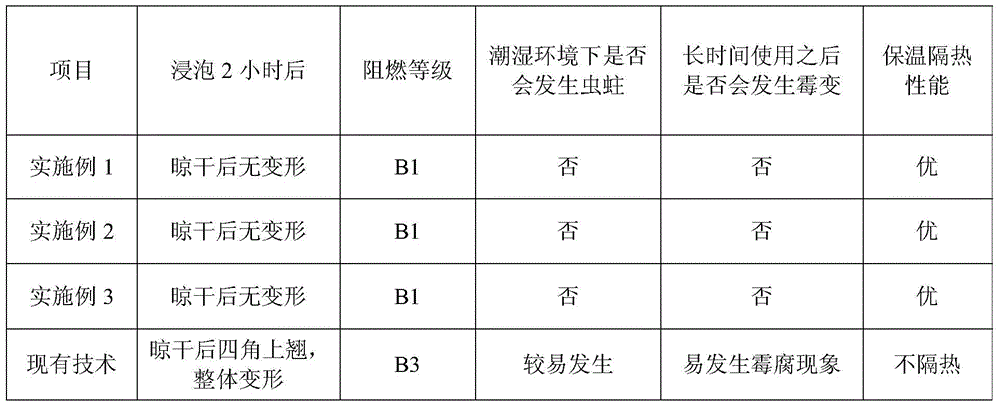

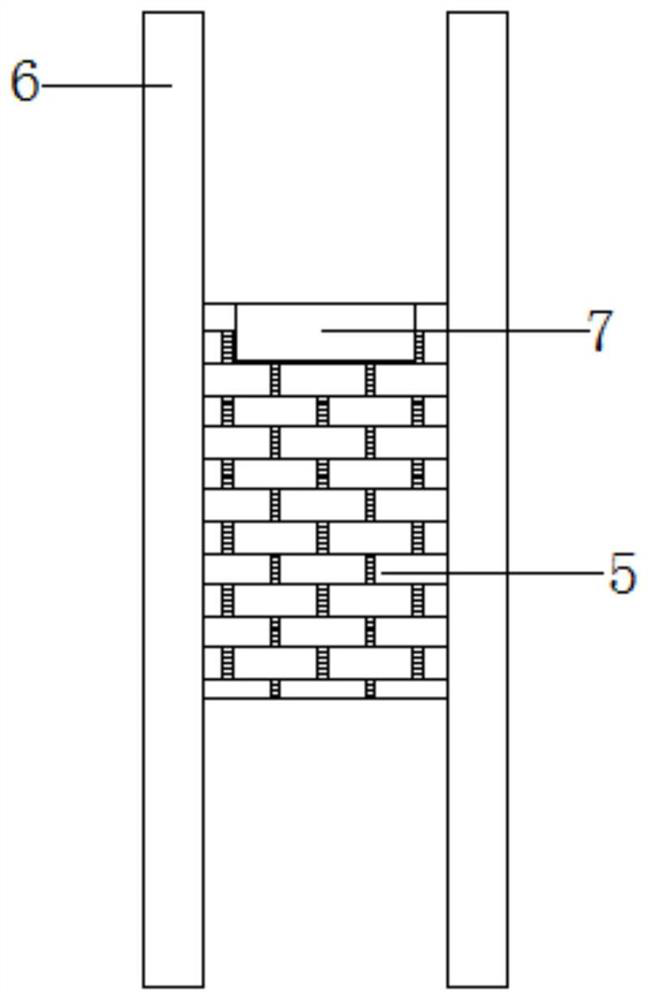

Novel composite board and preparation method thereof

ActiveCN104175660ASave resourcesRaw material environmental protectionSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

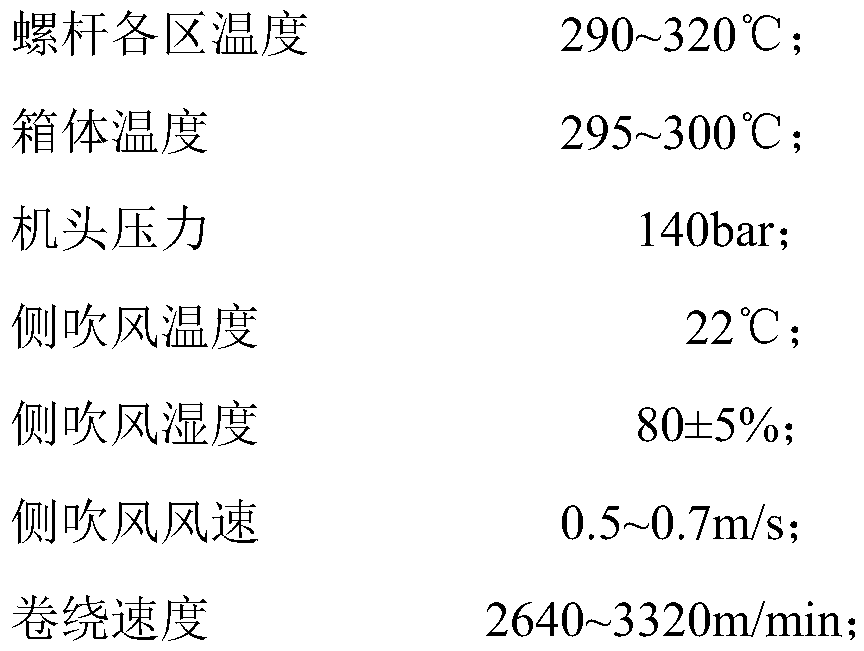

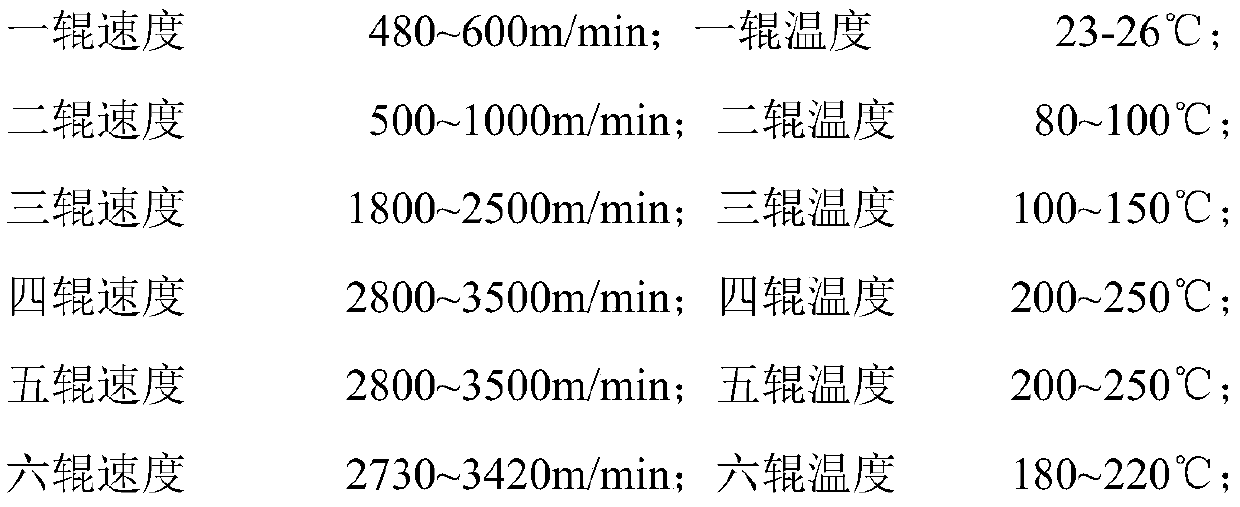

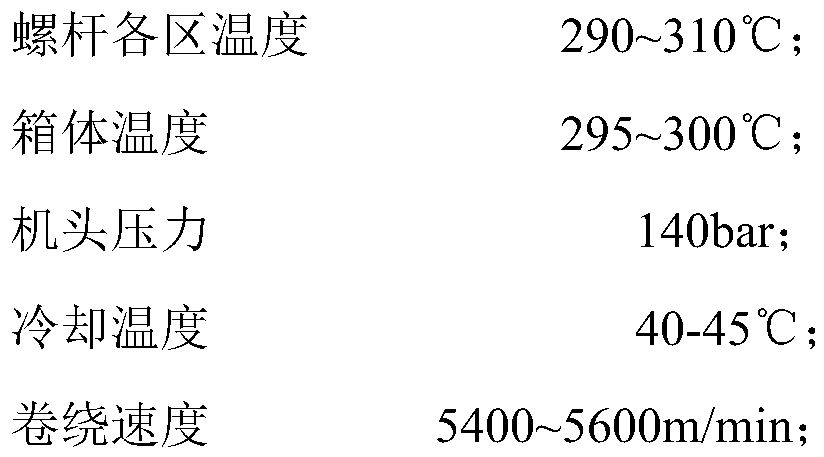

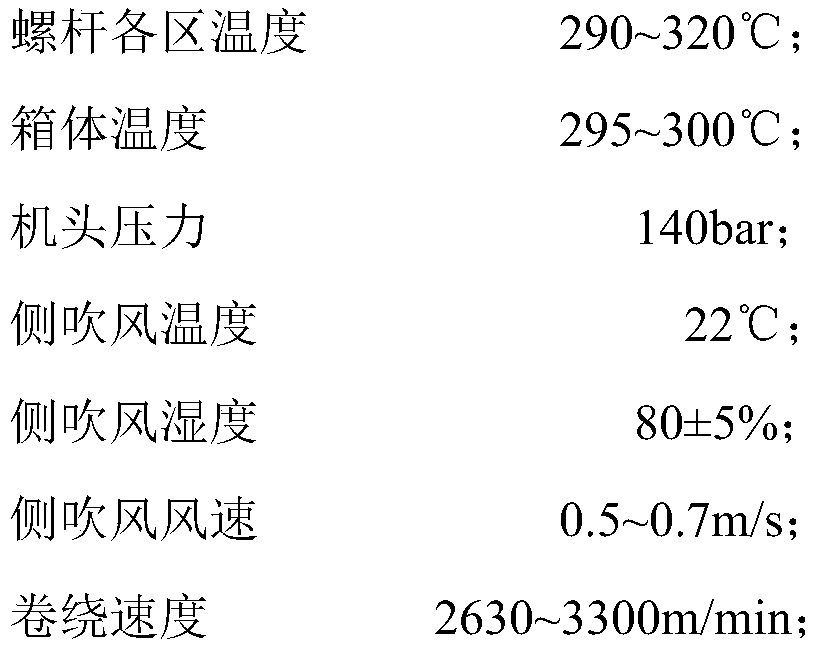

Double-component orange slice type compound fibers and preparation method thereof

ActiveCN109735955APromote degradationIncrease the free volume of spaceMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnFiber

The invention relates to double-component orange slice type compound fibers and a preparation method thereof. The preparation method comprises the following steps: first, uniformly mixing terephthalicacid, 1,4-butanediol, dihydric alcohol with a tertiary butyl side group, binary acid with a tertiary butyl side group and doped and modified Bi2O3 powder, and successively carrying out esterificationreaction and polycondensation to prepare modified polyester; and carrying out metering, extruding in a same yarn spray hole in an orange slice type yarn spray plate, cooling, oiling, stretching, thermal setting and coiling on a modified polyester melt and a chinlon melt by means of a compound spinning method to prepare the double-component orange slice type compound fibers, wherein the doped andmodified Bi2O3 powder is dispersed in chinlon. The intrinsic viscosity of the product placed for 60 months at a temperature of 25 DEG C and relatively humidity of 65% is reduced by 16-21%. The intrinsic viscosity of the modified polyester is reduced by 14-19%. The preparation method is simple in process and low in cost. The prepared product is high in natural degrading rate and good in applicationprospect.

Owner:JIANGSU HENGLI CHEM FIBER

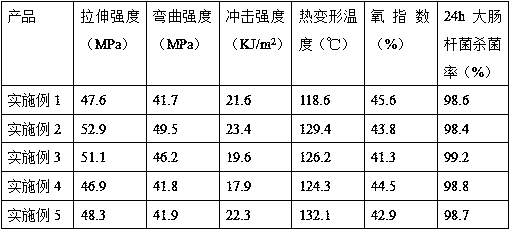

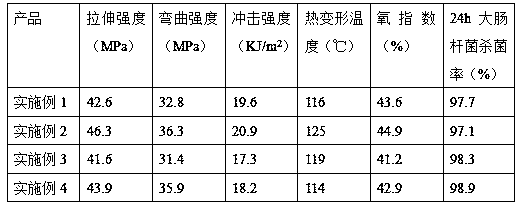

Anti-bacterial and flame-retardant PVC composite board and processing method thereof

The invention discloses an anti-bacterial and flame-retardant PVC composite board and a processing method thereof, wherein the anti-bacterial and flame-retardant PVC composite board includes the following raw materials in parts by weight: 100 parts of PVC resin, 5-10 parts of an acrylic acid-maleic anhydride copolymer, 40-60 parts of wood meal, 40-60 parts of modified calcium carbonate, 5-10 partsof shell powder, 3-5 parts of boron nitride, 1-3 parts of aramid fibers, 2-4 parts of a foaming agent, 1-2 parts of a flame retardant, 1-2 parts of an antibacterial agent, 1-3 parts of a plasticizer,0.5-1.5 parts of a stabilizer, 0.5-1.5 parts of an antioxidant, 2-4 parts of a modifier and 3-5 parts of a processing aid. The modifier consists of octaaminophenyl cage-like silsesquioxane and vegetable oil fatty acid alkanolamide borate with a mass ratio of (1-3):1. The prepared PVC composite board has the advantages of high strength, strong impact resistance, no fission, good flame retardancy,strong antibacterial property, low water absorption rate, wear resistance, weather resistance, heat resistance, difficult deformation, aging resistance, good processing performance, simple process, low cost, and good social and economic benefits.

Owner:钦州市宝业坭兴陶厂

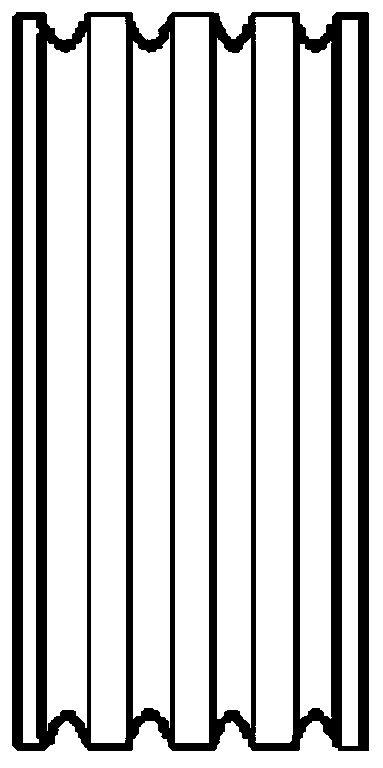

Calcium carbonate enhanced PVC composite board and processing method thereof

InactiveCN108864590AImprove flame retardant performanceImprove stabilityPhytic acidPolydimethyl siloxane

The invention discloses a calcium carbonate enhanced PVC composite board and a processing method thereof. The composite board comprises the following raw materials in parts by weight: 100 parts of PVCresin, 10-20 parts of calcium lignosulphonate, 40-80 parts of wood flour, 40-60 parts of modified calcium carbonate, 3-5 parts of aramid fiber, 3-5 parts of sepiolite fiber, 1-3 parts of polyether modified polydimethylsiloxane, 2-4 parts of polyoxyethylene glycerol ether monostearate, 1-3 parts of composite foaming agent, 2-4 parts of coupling agent, 1-2 parts of stabilizing agent, 2-4 parts of lubricating agent, 1-2 parts of antioxidant and 3-5 parts of processing agent. The modified calcium carbonate adopted by the invention is subjected to surface modification with ceraphyl RMT and polyoxypropylene polyoxyethylene propylene glycol ether and then is subjected to secondary surface modification with aminopropyl Poly(methylsilsesquioxane) and phytic acid. The PVC composite board prepared by the invention has the advantages of high strength, high toughness, high impact resistance, excellent fire resistance, wear resistance, heat resistance, difficulty in deformation, high stability, andthe like, and can be widely applied to the construction fields of wood floors, ceilings, wallboards, and the like.

Owner:贺州钟山县双文碳酸钙新材料有限公司

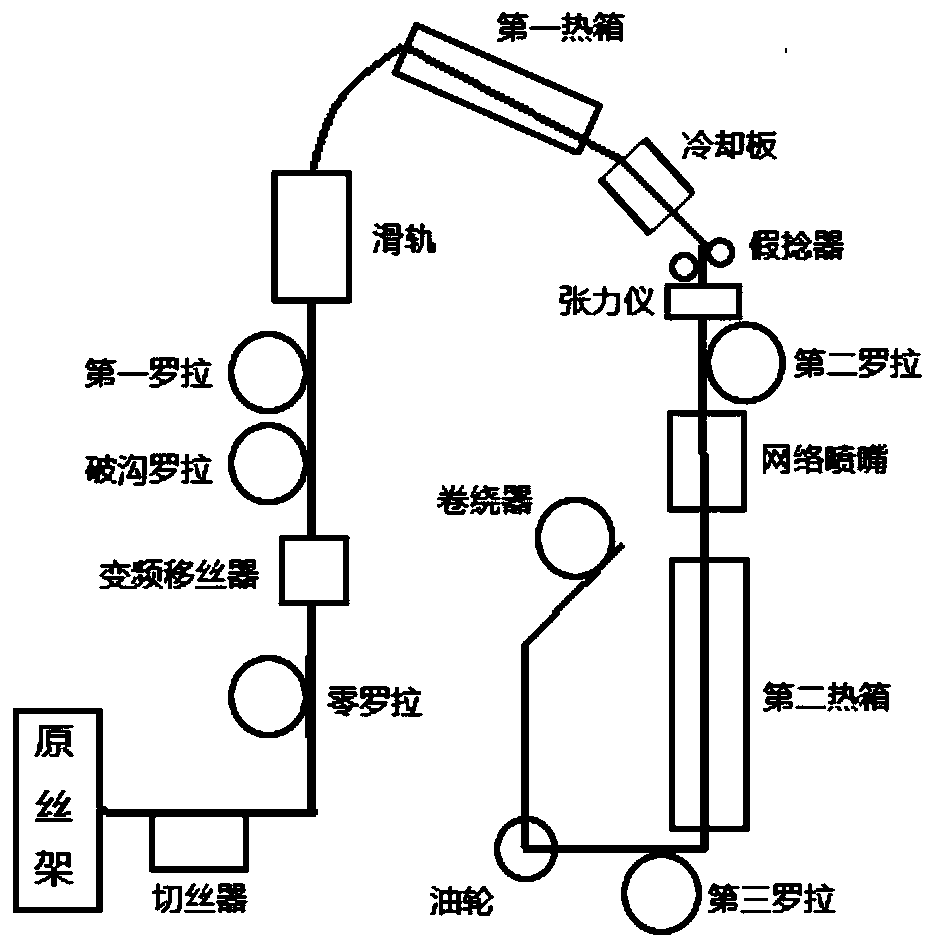

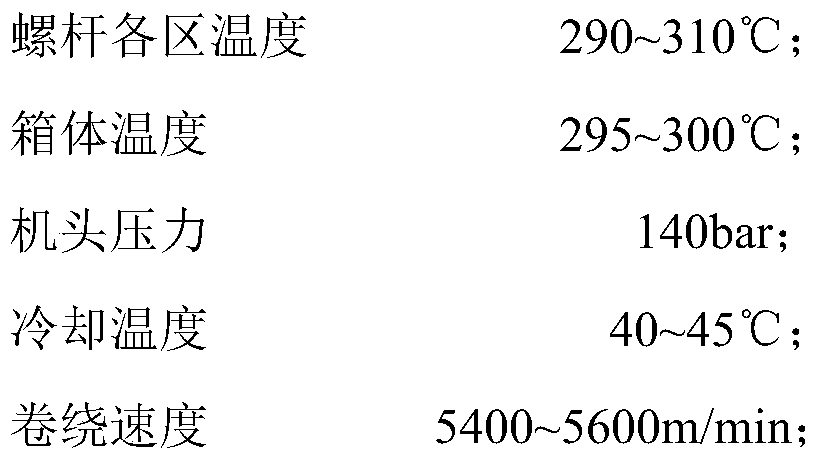

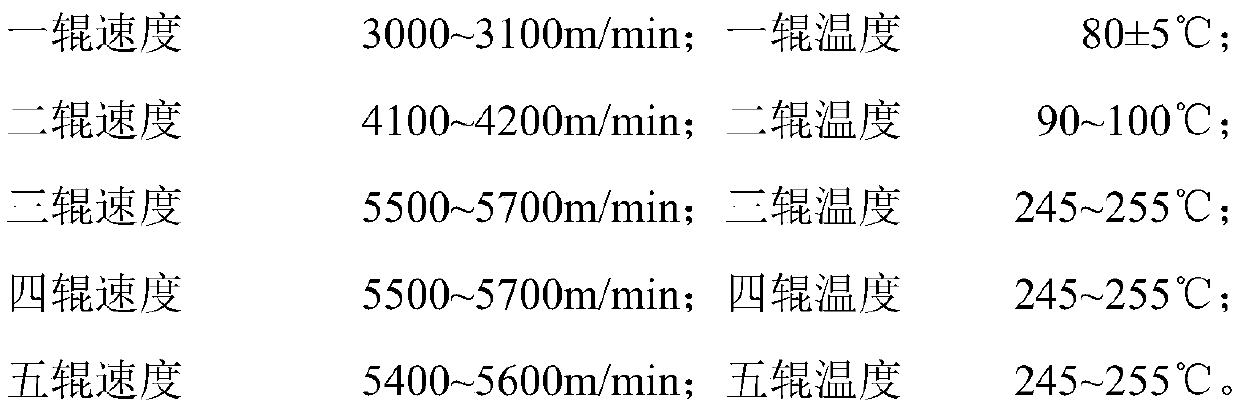

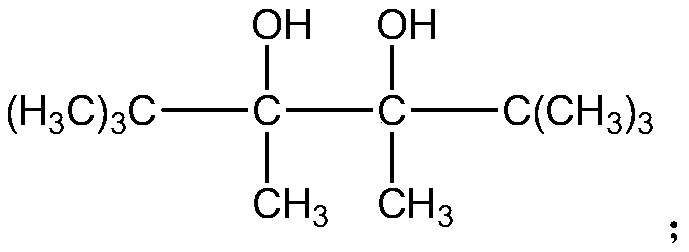

Method for preparing floating flax-like polyester fibers

ActiveCN109735940AIncrease the free volume of spaceIncrease the void free volumeArtificial filament heat treatmentMelt spinning methodsYarnFiber

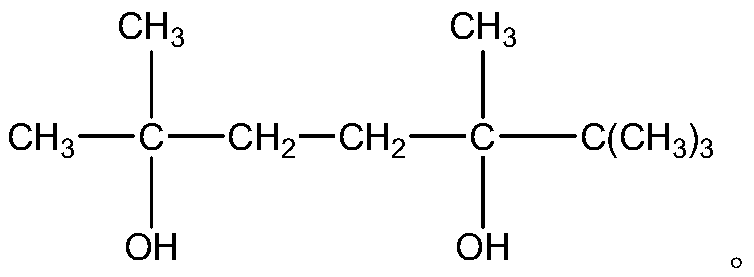

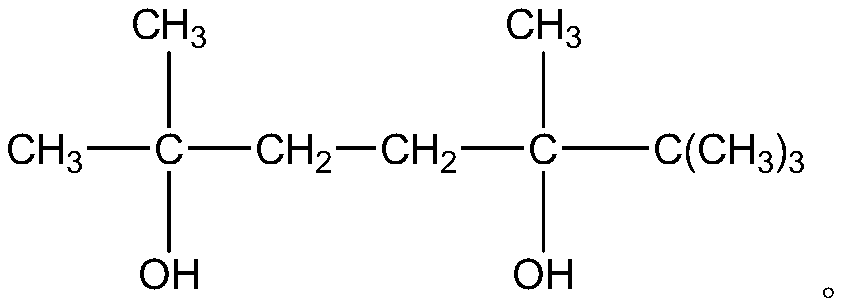

The invention relates to a method for preparing floating flax-like polyester fibers. The method comprises the following steps: preparing modified polyester POY yarns from modified polyester melt according to a POY process, processing the yarns according to a DTY process, arranging a trench-breaking roller and a variable frequency shifter between a zero roller and a first roller of DTY equipment, enabling modified polyester tows to pass through the surface of the trench-breaking roller, and dyeing, thereby obtaining the floating flax-like polyester fibers. The preparation method of the modifiedpolyester comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol and 2,5,6,6-tetramethyl-2,5-heptandiol, and sequentially carrying out an esterification reaction and a condensation polymerization reaction so as to prepare modified polyester. The trench-breaking roller is a roller on the peripheral surface of which multiple ring grooves are formed; the variable frequency shifter is used for driving the polyester POY yarns to make a reciprocating motion on the peripheral surface of the trench-breaking roller along a center shaft of the roller; and the movement cycleof the variable frequency shifter is 5-99 reciprocal times per minute. The method disclosed by the invention is easy to operate, and the prepared fiber is excellent in dyeing property and air permeability and has excellent application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Method for modification of nano calcium carbonate for flame-retardant PVC plates and application

Owner:钦州市宝业坭兴陶厂

Wool-like polyester filament and preparation method thereof

ActiveCN109750372AIncrease the free volume of spaceIncrease the void free volumeMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentPolymer scienceNatural degradation

The invention relates to a wool-like polyester filament and a preparation method thereof. The preparation method comprises the steps: firstly, terephthalic acid, 1,4-butanediol, fluorinated diacid, hexanediol with tertiary butyl side groups, and 2,5,6,6-tetramethyl-2,5-heptanediol are evenly mixed, and then an esterification reaction and a polycondensation reaction are carried out successively toprepare modified polyester; then a modified polyester POY filament is prepared from modified polyester flux according to a POY process; and finally a modified polyester DTY filament is prepared from the modified polyester POY filament according to a DTY process, and then the wool-like polyester filament is obtained. According to a prepared product, when the temperature is 100 DEG C, the dye-uptakeis 90.32-93.27%, and the K / S value is 22.15-23.42; after the product is placed at temperature of 25 DEG C and the relative humidity of 65% for 60 months, the intrinsic viscosity of the product is lowered by 17-20%; and the preparation method is low in cost and simple in process, and the prepared product is excellent in dyeing property and high in natural degradation speed, and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

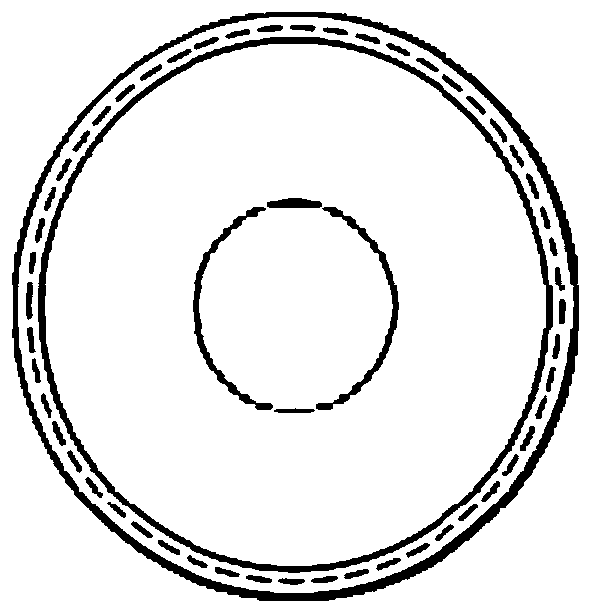

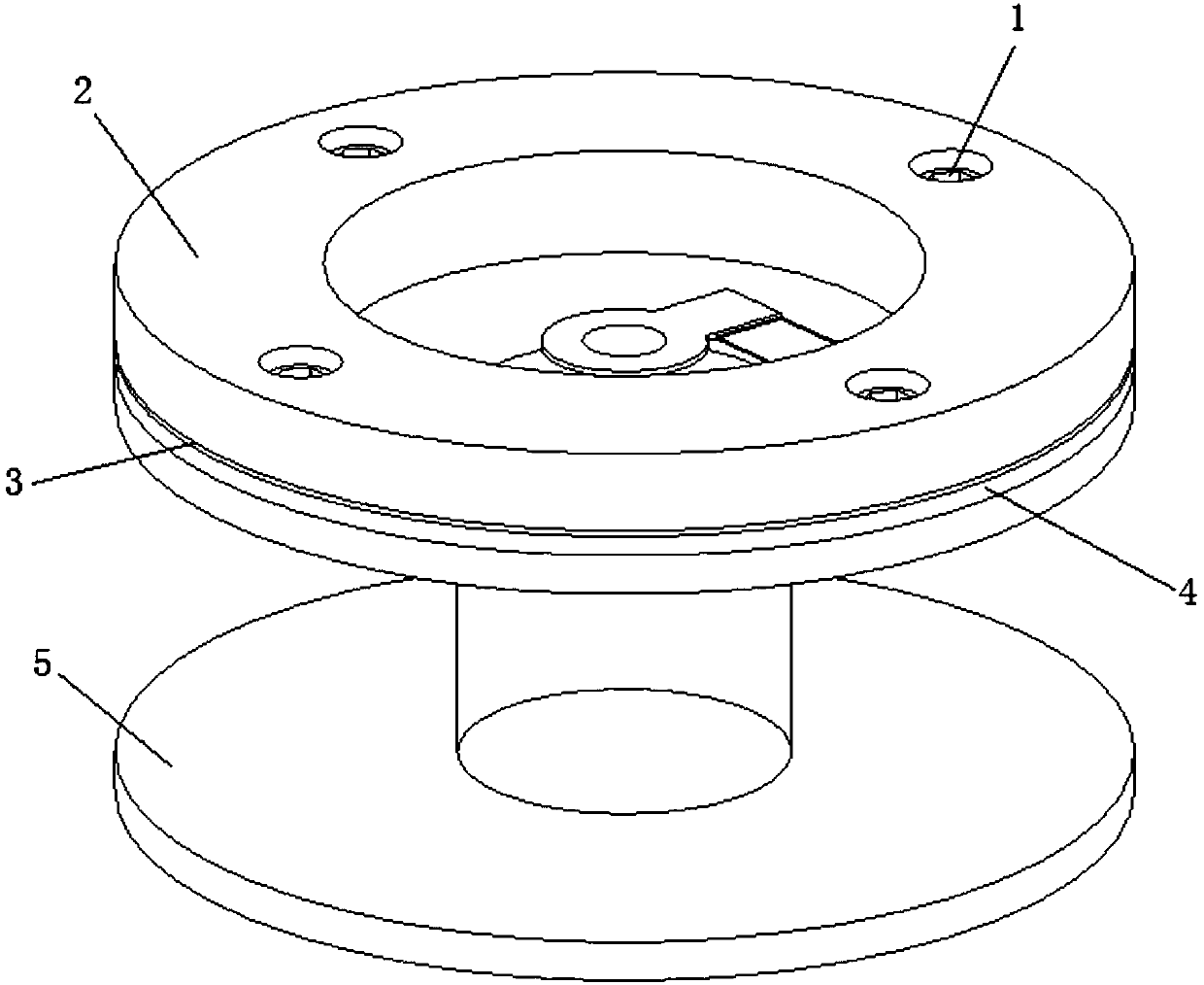

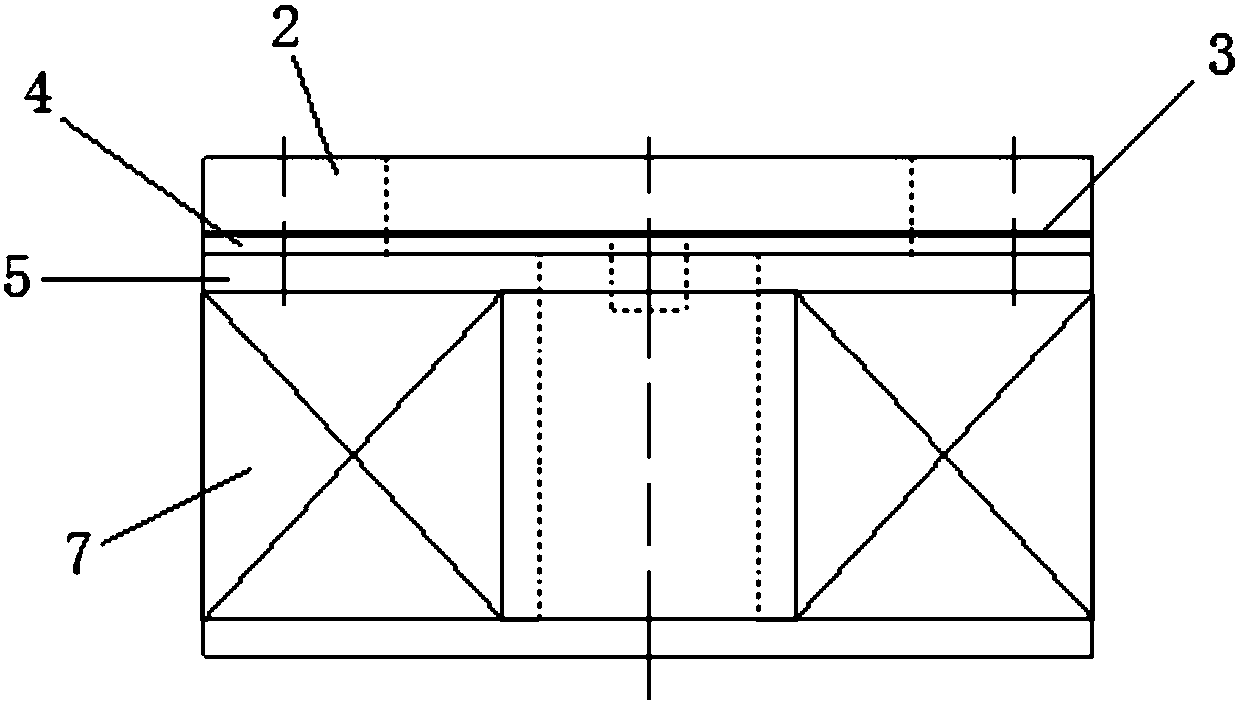

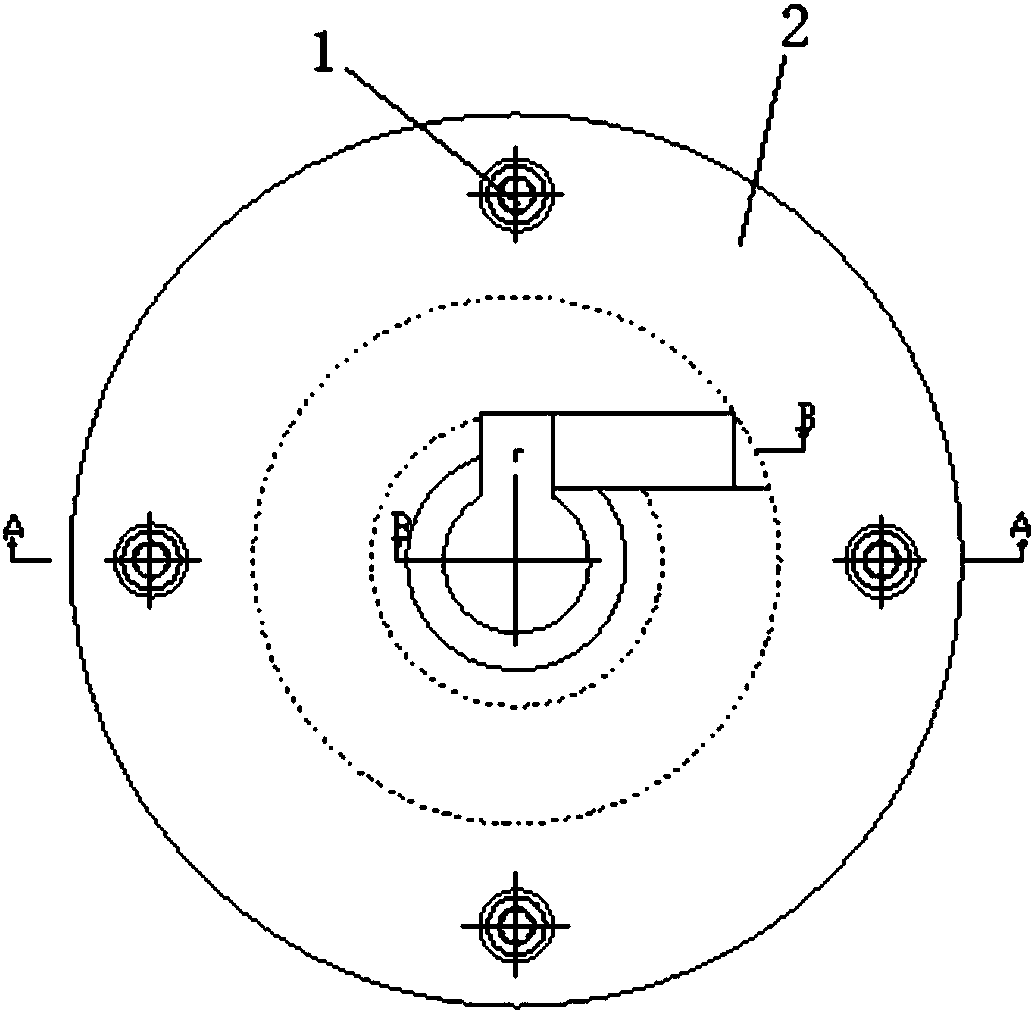

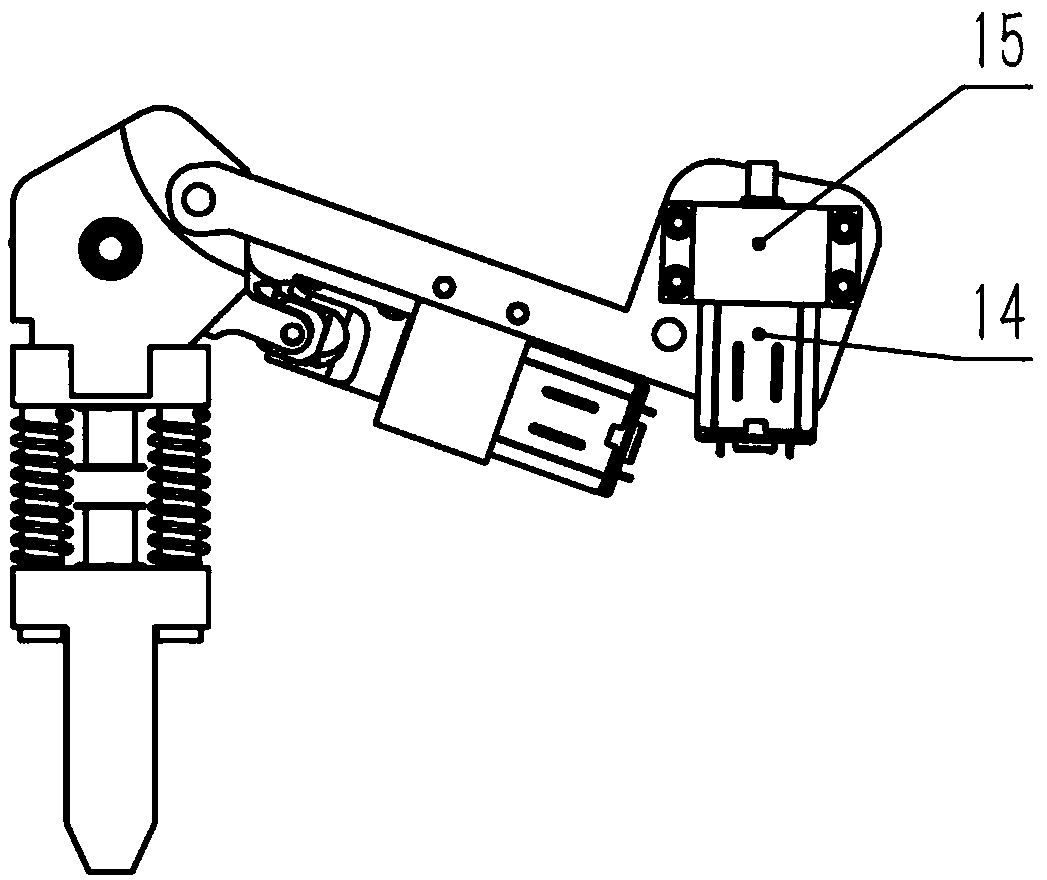

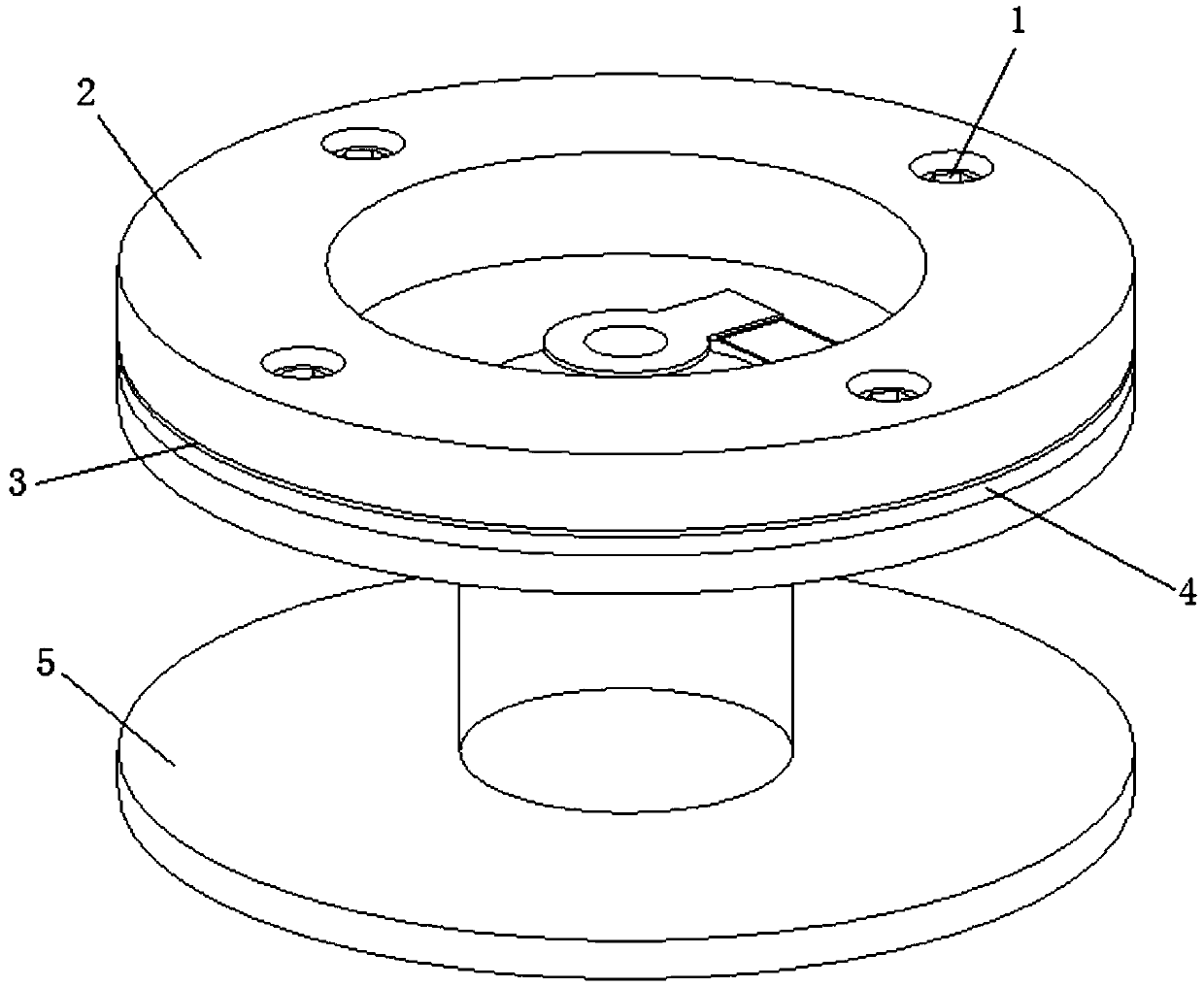

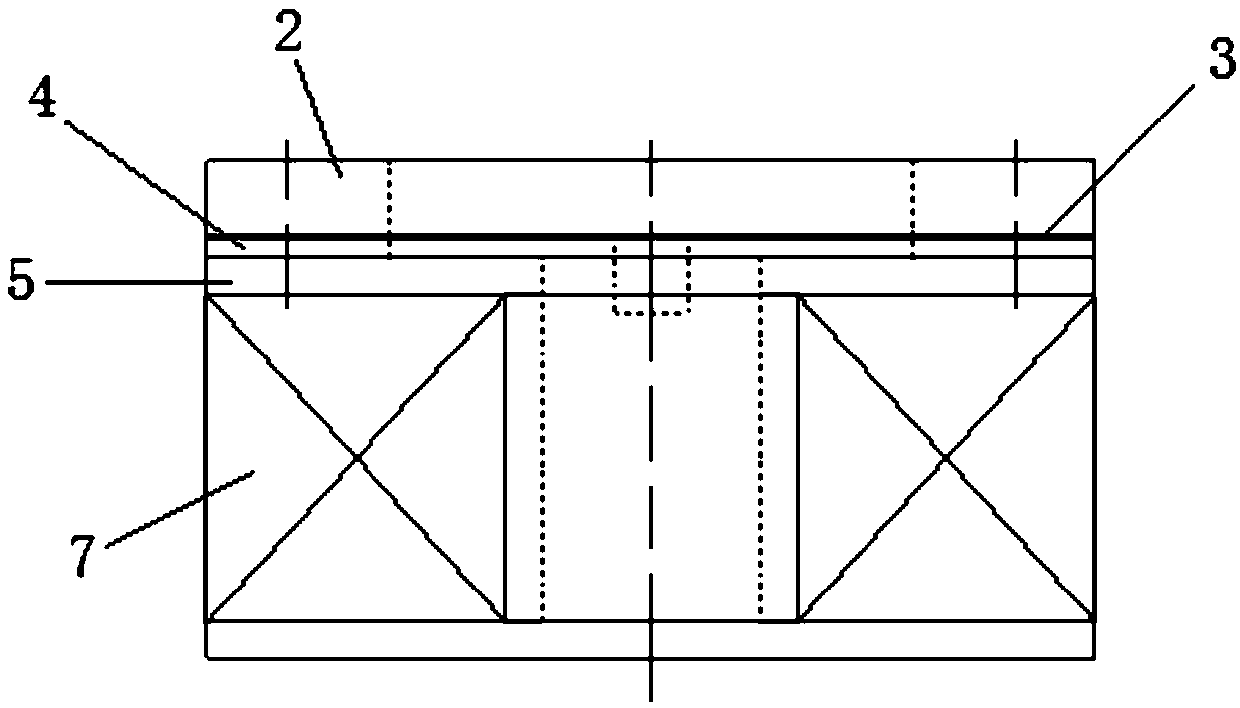

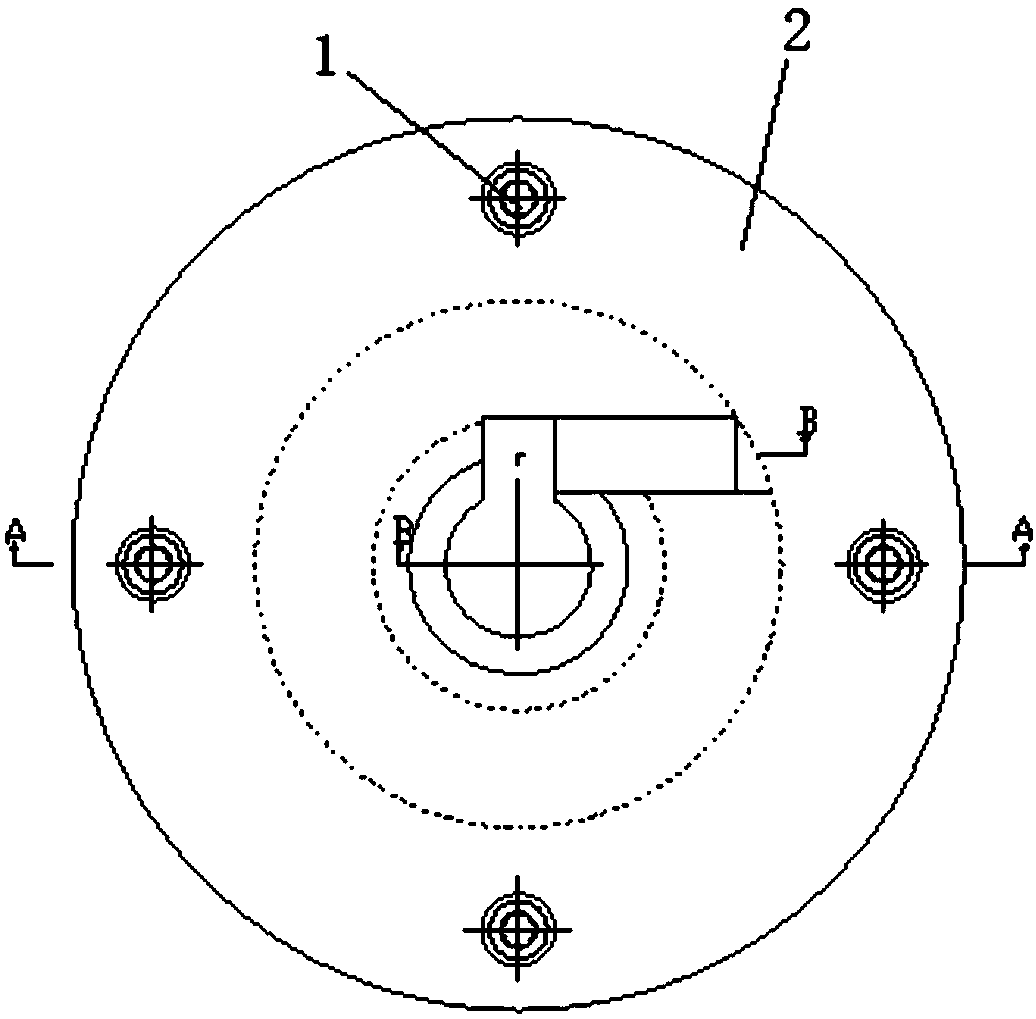

Electromagnetic-type generation device with high precision and super-micro force

InactiveCN107640736AChange interaction forceChange intensityTelevision system detailsForce measurement by measuring magnetic property varationCantilevered beamEngineering

The invention discloses an electromagnetic-type generation device with high precision and super-micro force. The device comprises an annular end cover, a cantilever beam component and a base body which are connected from top to bottom in sequence, the base body is arranged to be in a cylindrical shape with an axial cavity, an annular groove is formed in the outer wall of the base body along the circumference, and a winding coil winds the interior of the annular groove; the cantilever beam component comprises an annular fixing base, a cantilever is connected to the inner circle of the fixing base, and a mounting sheet is connected to the cantilever; the fixing base, the cantilever and the mounting sheet are arranged to be an integrated structure, and a columnar permanent magnet is arrangedon the bottom of the mounting sheet. According to the electromagnetic-type generation device, the micro-Newton level and nano-Newton level applied force can be precisely generated, and the device hasthe advantages of high precision, high response speed and the like and is suitable for a system driven by precise super-micro force.

Owner:TIANJIN UNIV

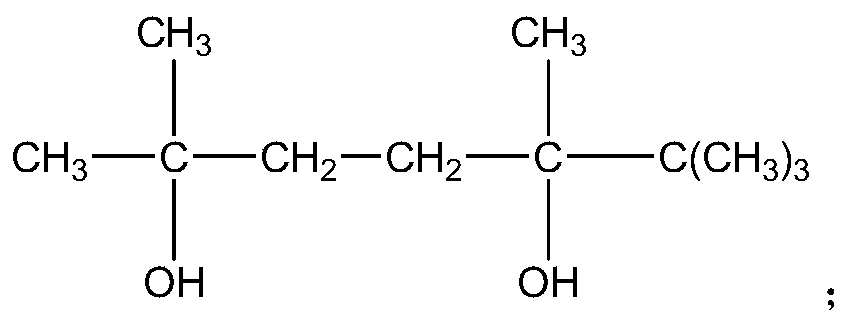

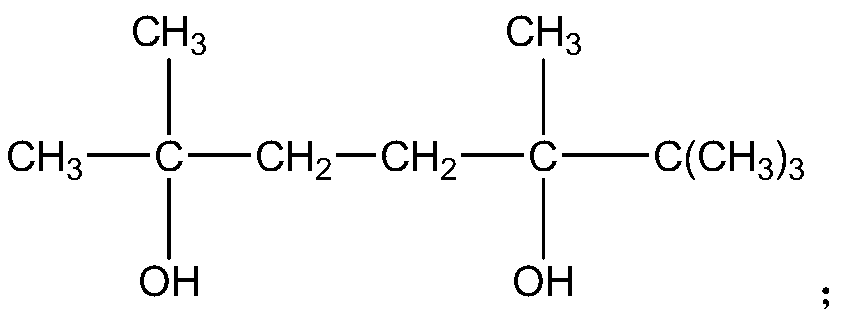

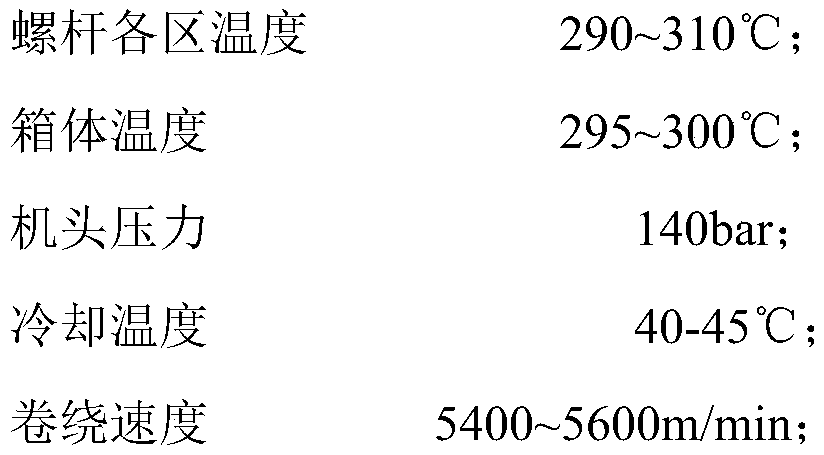

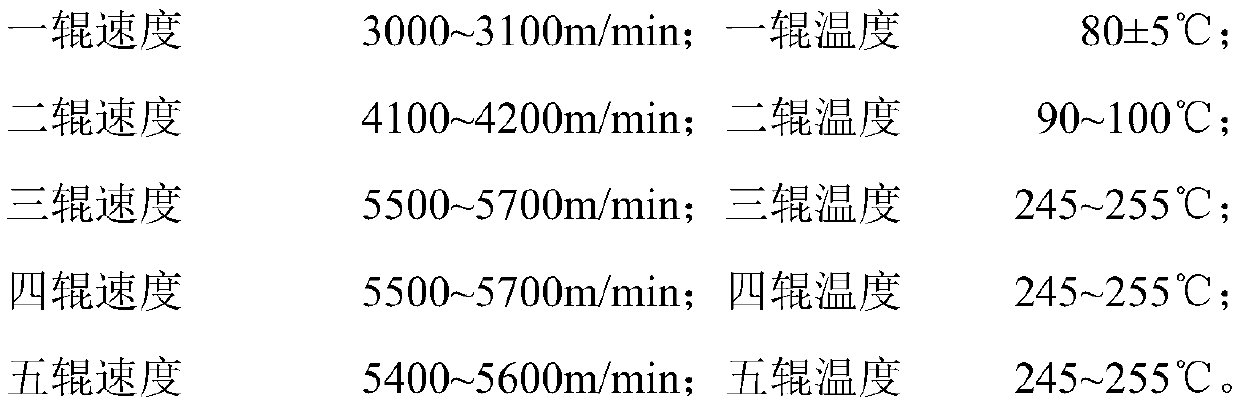

Polyester heat-resistant canvas and preparation method thereof

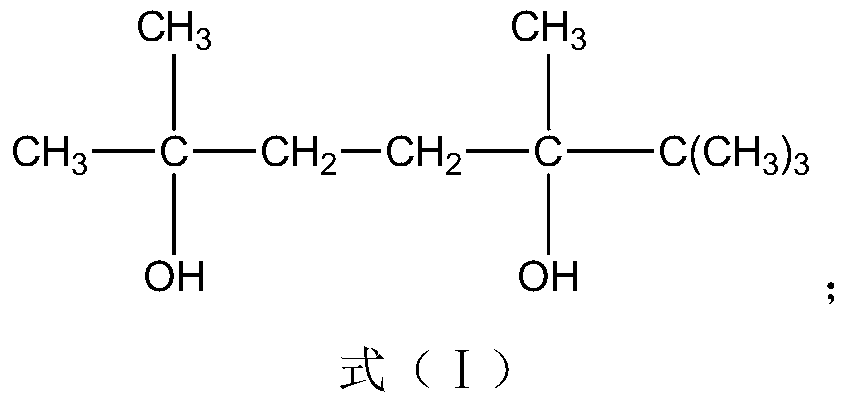

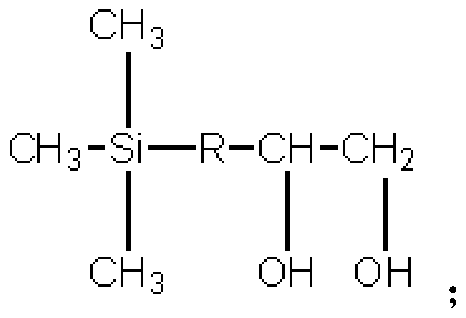

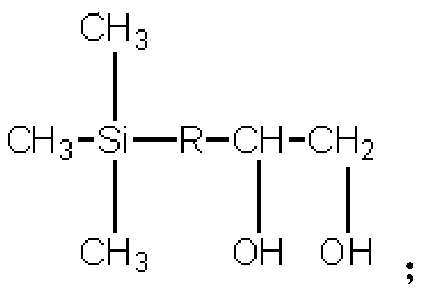

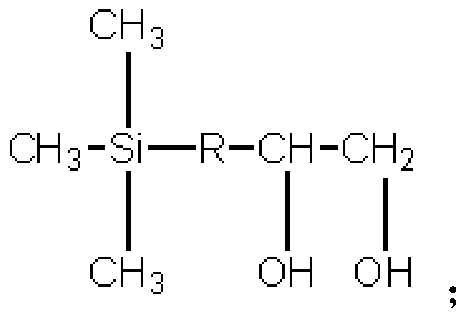

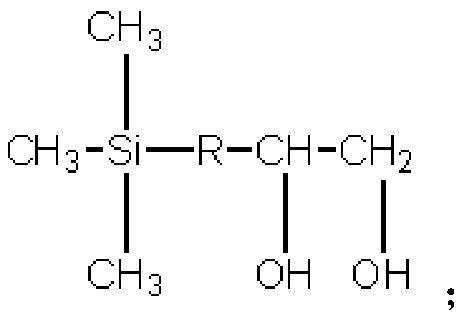

ActiveCN109750376AIncrease the free volume of spaceChange interaction forceFibre typesSynthetic resin layered productsYarnTert butyl

The invention relates to polyester heat-resistant canvas and a preparation method thereof. The preparation method comprises the steps that after modified polyester industrial yarn weaving cloth is padded with RFL impregnation liquid, a rubber layer is calendered on the surface of the modified polyester industrial yarn weaving cloth, then vulcanizing is conducted, and thus the polyester heat-resistant canvas is prepared; the modified polyester industrial yarn is prepared from a modified polyester melt through solid-phase polycondensation viscosity increasing, melting, metering, extruding, cooling, oiling, stretching, thermal shaping and winding; and a preparation method of modified polyester before solid-phase polycondensation viscosity increasing comprises the steps that terephthalic acid,ethylene glycol, dihydric alcohol with a trimethylsilyl pendant group, and dihydric alcohol with a tert-butyl pendant group are mixed evenly and then subjected to esterification reaction and polycondensation reaction successively; and the peeling grade of a prepared product is five, the use temperature range is minus 50 DEG C to plus 150 DEG C, the tear strength is greater than or equal to 7.0 N / mm, and the bonding strength is greater than or equal to 7.0 N / mm. The preparation method is simple in technology and low in cost; and the prepared product is high in bonding strength and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Flame-retardant polyester fiber and preparation method thereof

ActiveCN109706542AIncrease the free volume of spaceIncrease the void free volumeMonocomponent polyesters artificial filamentArtifical filament manufactureFiberYarn

The invention relates to a flame-retardant polyester fiber and a preparation method thereof. The preparation method includes the step that modified polyester FDY yarn, namely the flame-retardant polyester fiber, is prepared from a modified polyester melt according to the FDY process. A preparation method of modified polyester comprises the step that terephthalic acid, ethylene glycol, 2-CEPPA, 2,5,6,6-tetramethyl-2,5-heptandiol and doped modified Bi2O3 powder are evenly mixed and subjected to an esterification reaction and a polycondensation reaction in sequence, wherein the structural formulaof 2,5,6,6-tetramethyl-2,5-heptandiol is shown in the description. The dye-uptake of the prepared product is 85.3-89.2% under the temperature condition of 120 DEG C, and the K / S value is 22.35-25.43;after the product is placed for 60 months under the condition that the temperature is 25 DEG C and the relative humidity is 65%, the characteristic viscosity of the product is reduced by 13-18%. Thepreparation method is low in cost and simple in process; the prepared product has excellent dyeing property and natural degradability.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing light tent cloth

ActiveCN109930232AHigh tensile strengthHigh peel strengthSynthetic resin layered productsLaminationYarnConductor Coil

The invention relates to a method for preparing a light tent cloth. The light tent cloth is prepared by dyeing, warping, weaving modified polyester industrial yarns and calendering and laminating witha TPU film, wherein the modified polyester industrial yarns are prepared by carrying out solid-phase polycondensation tackifying, melting, metering, extruding, cooling, oiling, stretching, heat setting, relaxation heat treatment and winding on a modified polyester melt; the method for preparing the modified polyester before the solid-phase polycondensation tackifying comprises the following stepsof: uniformly mixing terephthalic acid, ethylene glycol and dihydric alcohol with trimethylsilyl side groups, carrying out esterification reaction and polycondensation reaction sequentially, whereinthe relaxation heat treatment refers to that the modified polyester industrial yarns pass through a certain temperature space in a proper state of relaxation, the proper state of relaxation refers tothat the overfeed rate of winding is 3.0-5.0 %, the certain temperature is 200-240 DEG C; the preparation method is simple, the cost is low, and the prepared light tent cloth has the advantages of good tensile strength, high peel strength, low thermal shrinkage and wide application range.

Owner:JIANGSU HENGLI CHEM FIBER

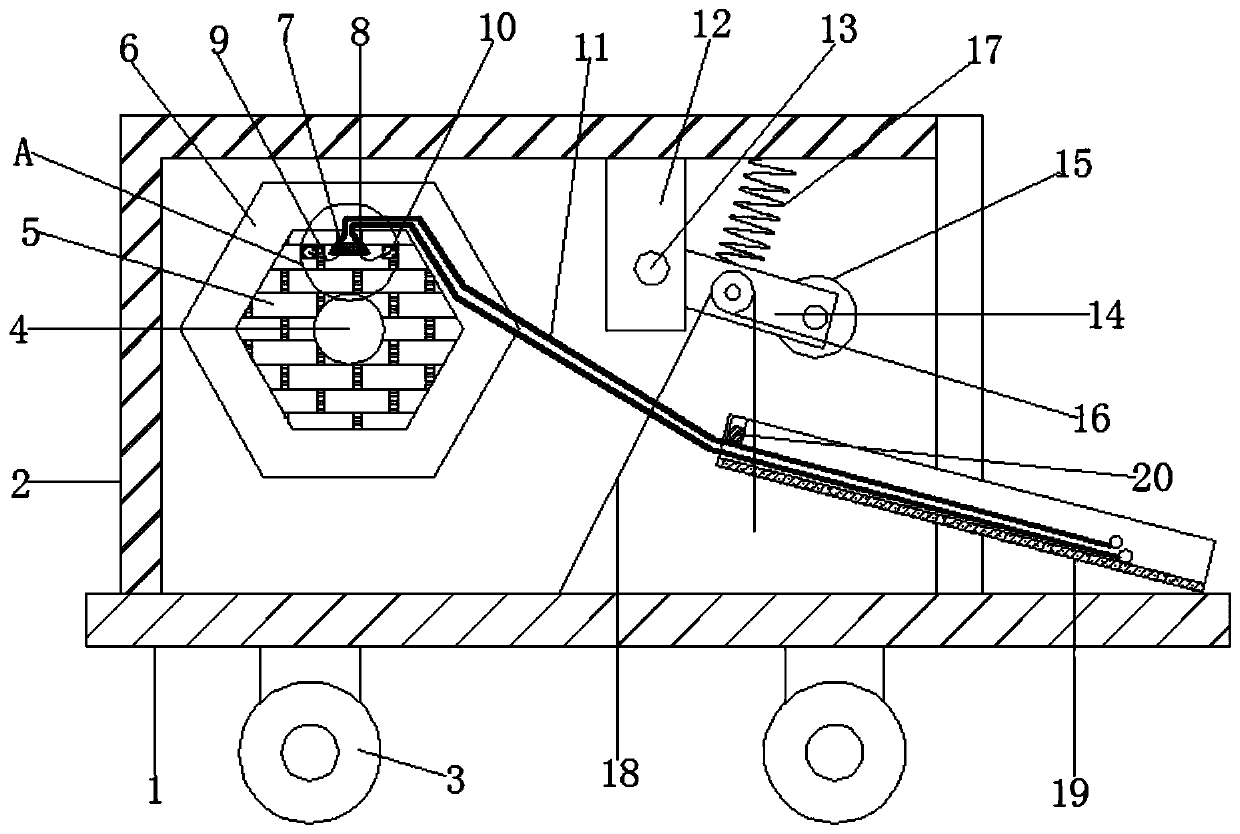

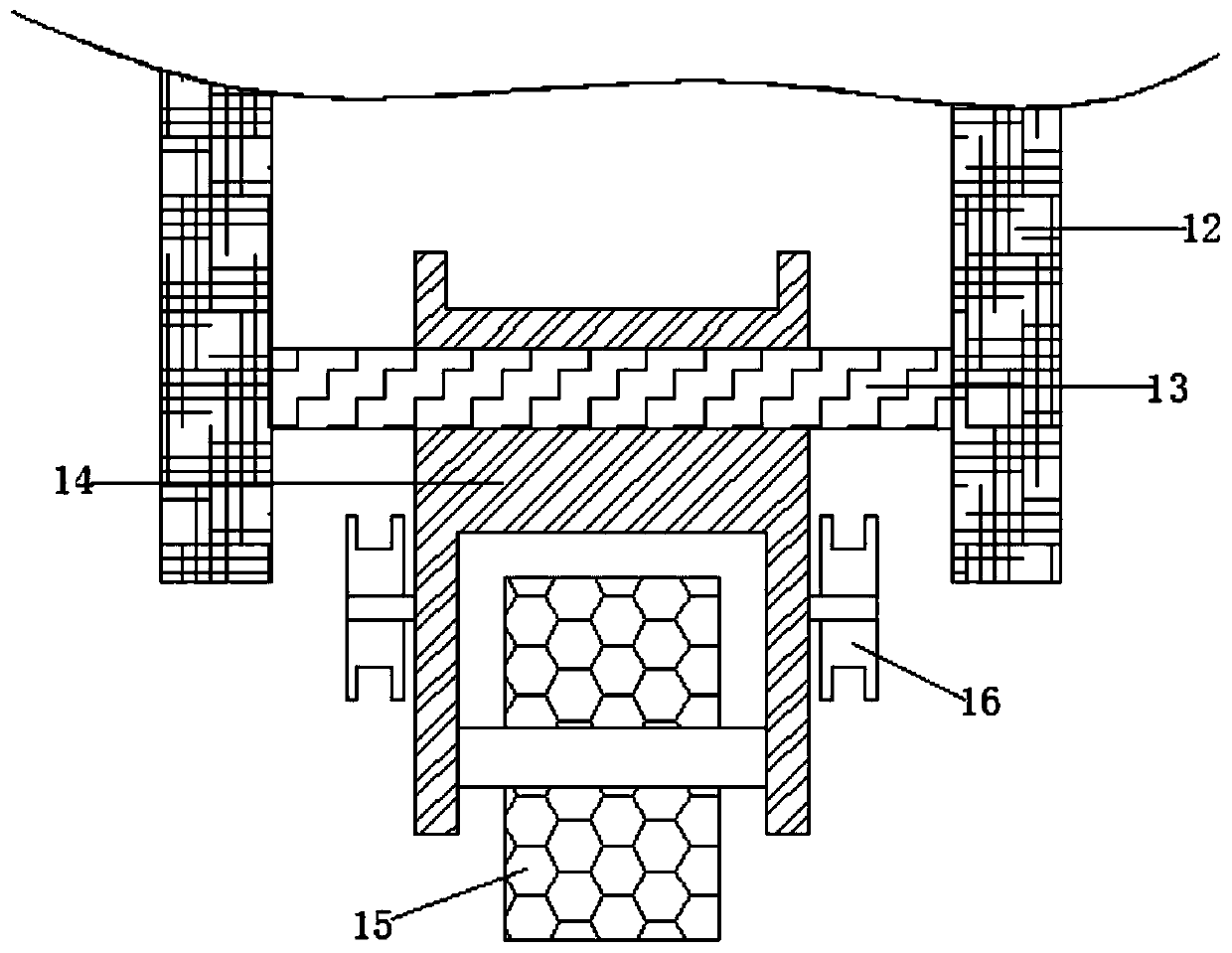

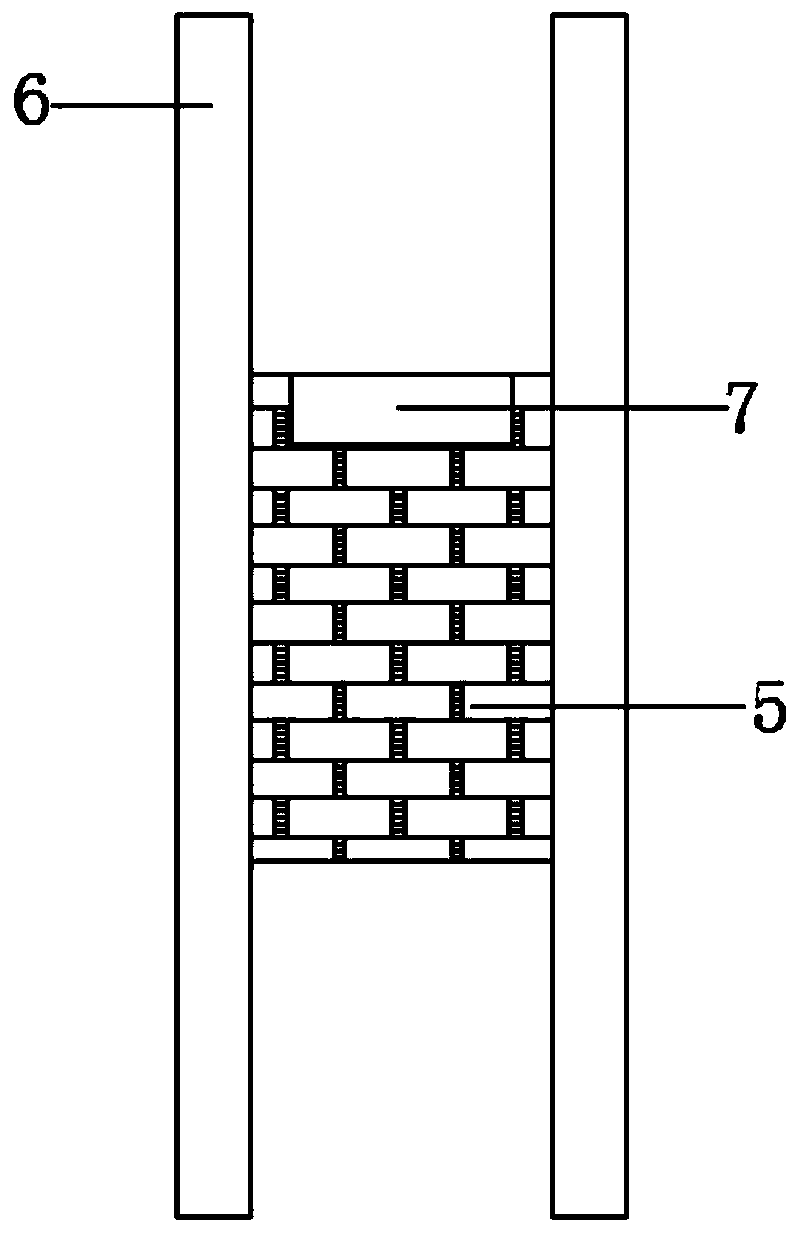

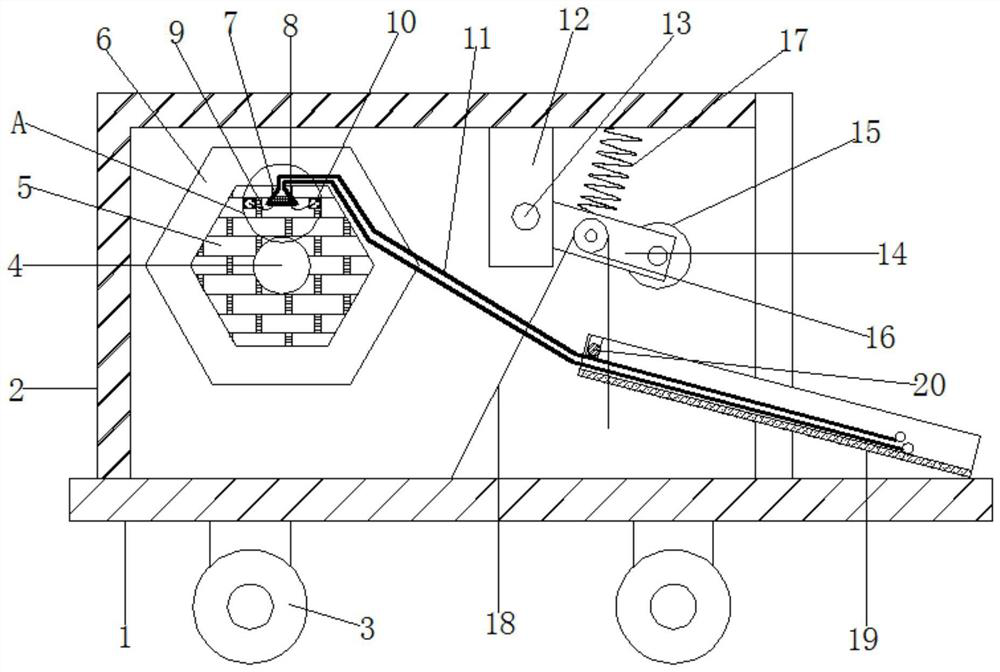

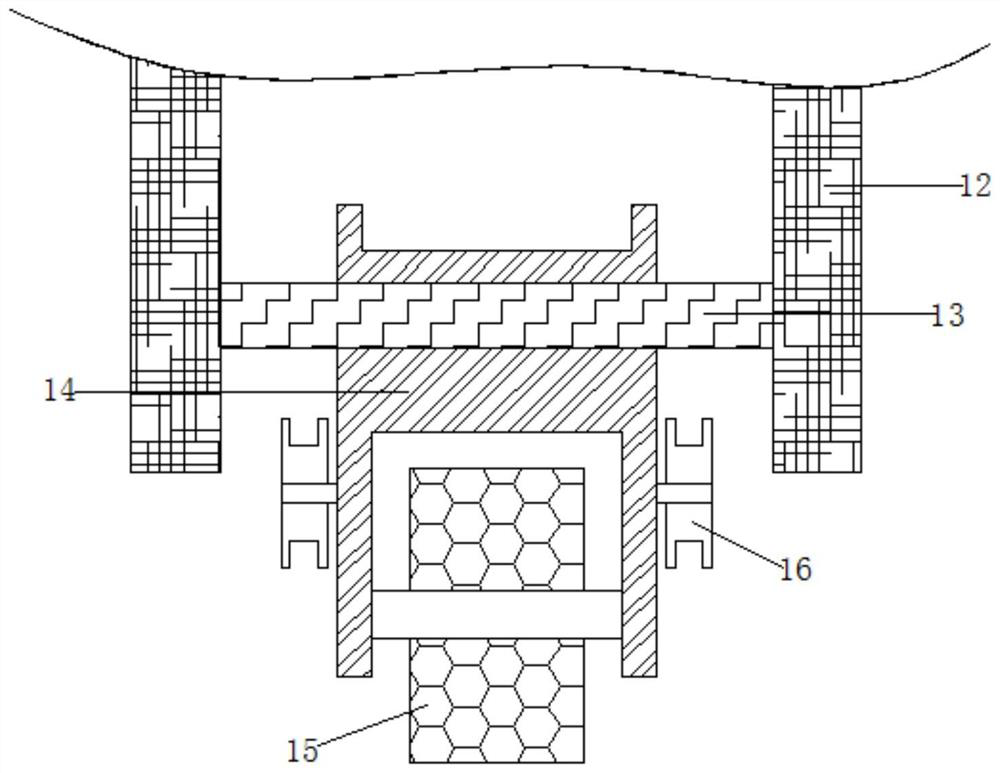

Fire hose dewatering and winding device

The invention relates to the technical field of fire hoses, and discloses a fire hose dewatering and winding device. The fire hose dewatering and winding device comprises a bottom plate and a shell; awinding disc is arranged inside the shell; a fixed hole is formed in the winding disc; a fixed block is arranged at the lower part of the fixed hole; a water hose is clamped between the fixed block and the winding disc; a movable frame is arranged in the shell; a friction roller is fixedly connected to the movable frame; a fixed pulley is fixedly connected to the side surface of the movable frame; a spring is fixedly connected between the movable frame and the shell; a lock chain is fixedly connected to the bottom plate; one end of the lock chain bypasses the fixed pulley; a slideway is fixedly connected to the right part of the shell; and a pressing rod is arranged at the left end of the slideway. According to the fire hose dewatering and winding device, water in the water hose is extruded out under the action of impact of six corners of the winding disc on the water hose and the inclined slide way, and the device has the advantages that the water hose can be dewatered and wound anddeicing slag treatment can be carried out.

Owner:南通亚龙消防器材有限公司

Polyester industrial yarn for automobile air bags and preparation method of polyester industrial yarn

ActiveCN109750367AIncrease the free volume of spaceIncrease the void free volumeMonocomponent copolyesters artificial filamentYarnPolymer science

The invention relates to polyester industrial yarn for automobile air bags and a preparation method of the polyester industrial yarn. The preparation method includes the step: the polyester industrialyarn for the automobile air bags is obtained after a modified polyester melt is subjected to solid phase condensation polymerization viscosification and a spinning technology. A preparation method ofmodified polyester before solid phase condensation polymerization viscosification includes the steps: terephthalic acid, ethylene glycol, diol with trimethylsilyl side groups, and 2,5,6,6-tetramethyl-2,5-heptanediol are mixed evenly and then subjected to an esterification reaction and a polycondensation reaction successively. The service life of the air bags made from the polyester industrial yarn is 8-12 years. The preparation method of the polyester industrial yarn is simple and low in cost, the polyester is modified by introducing the 2,5,6,6-tetramethyl-2,5-heptanediol and the diol with the trimethylsilyl side groups, by cooperating with a subsequent sizing process, wear resistance of the automobile air bags made of the industrial yarn is significantly improved, and the service life of the automobile air bags made from the industrial yarn is significantly prolonged; and manufactured products have excellent weaving and wear resistance, and good application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage polyester drawn yarn and preparation method thereof

ActiveCN109722735AIncrease the free volume of spaceChange interaction forceMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolymer science

The invention relates to a low-shrinkage polyester drawn yarn and a preparation method thereof. The preparation method comprises the steps that modified polyester is processed according to an FDY process, a relaxation heat treatment process is added between a tension heat setting process and a winding process, and then the low-shrinkage polyester drawn yarn is obtained; a preparation method of modified polyester comprises the steps that terephthalic acid, ethylene glycol, dihydric alcohol with a trimethylsilyl side group and binary acid with a tertiary butyl side group are mixed to be uniform,and then an esterification reaction and a condensation polymerization are conducted in sequence. The boiling water shrinkage of the prepared low-shrinkage polyester drawn yarn is 3.0+ / -0.5%, the dye-uptake is 86.3-89.8% at 125 DEG C, and the K / S value is 22.32-24.34. The preparation method has the advantages of being simple in process and low in cost, and the dyeing performance and heat shrinkageof the low-shrinkage polyester drawn yarn are low.

Owner:JIANGSU HENGLI CHEM FIBER

Water-repellent canvas and preparation method thereof

ActiveCN109735947AIncrease the free volume of spaceIncrease the void free volumeFibre typesMonocomponent polyesters artificial filamentYarnPolymer science

The invention relates to a water-repellent canvas and a preparation method thereof. The preparation method comprises the following steps: padding modified polyester industrial yarn woven cloth with awaterproof finishing agent, and coating a waterproof coating on the surface of the woven cloth, thereby obtaining the water-repellent canvas. The modified polyester industrial yarns are prepared by the following steps: performing solid phase polycondensation tackifying on modified polyester melt, melting, metering, extruding, cooling, oiling, stretching, heat setting and winding. The preparation method of the modified polyester before solid phase polycondensation tackifying comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol, dihydric alcohol with a tert-butyl side group and doped and modified Sb2O3 powder, and sequentially carrying out an esterification reaction and a condensation polymerization reaction so as to prepare modified polyester. The peel strengthof the prepared product is more than or equal to 10N / cm, the usage temperature ranges from 30 DEG C below zero to 60 DEG C, the hydrostatic pressure resistance value is more than or equal to 100KPa,and the friction resistance number is more than or equal to 3000. The preparation method disclosed by the invention is simple in process, the addition amount of an antimony catalyst is reduced, and the cost is low; and the prepared product is high in peel strength and excellent in application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing low-boiling-water fluffy chenille yarns

ActiveCN109680359AImprove dyeing effectGood flexibilityMonocomponent polyesters artificial filamentYarnPolymer science

The invention relates to a method for preparing low-boiling-water fluffy chenille yarns. The method comprises the following steps: processing modified polyester by a FDY process, additionally settinga relaxation thermal treatment process between a tension heat setting process and a winding process to obtain the low-boiling-water fluffy chenille yarns, wherein the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a ethylene glycol chain segment and a binary acid chain segment with a tertiary butyl side radical; the relaxation thermal treatment means that polyester tows pass through a space at a certain temperature in a proper relaxed state, namely the winding overfeed ratio being 3.0-5.0 percent, and certain temperature is 200-240 DEG C. According to the method, the binary acid chain segment with the tertiary butyl side radical is modified, and the fiber dyeing performance is improved; the thermal treatment temperature and the relatively high overfeed ration are matched with each other, so that the completeness of fiber crystallization is improved, and thermal contraction of the fibers in the application process can be reduced. The preparation method has simple process, low cost and good application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

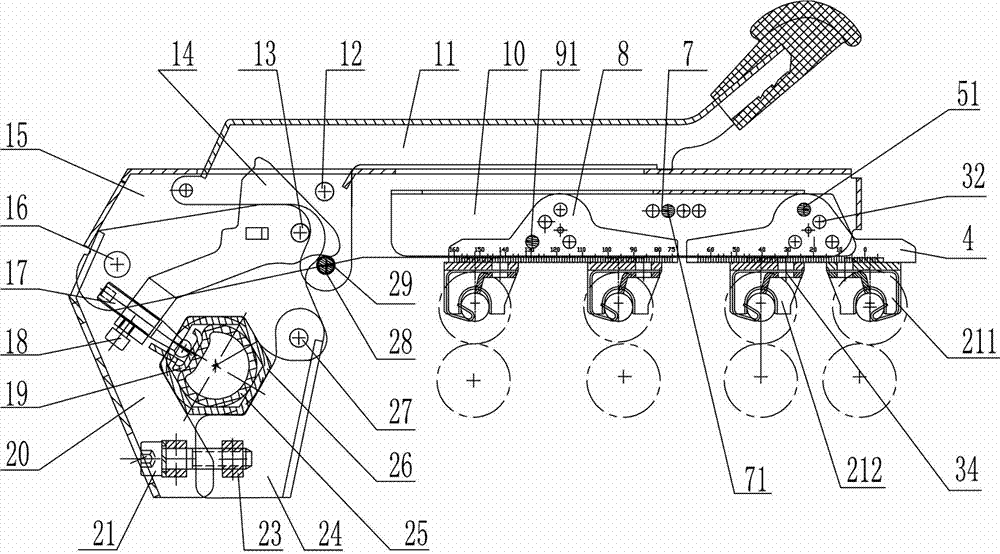

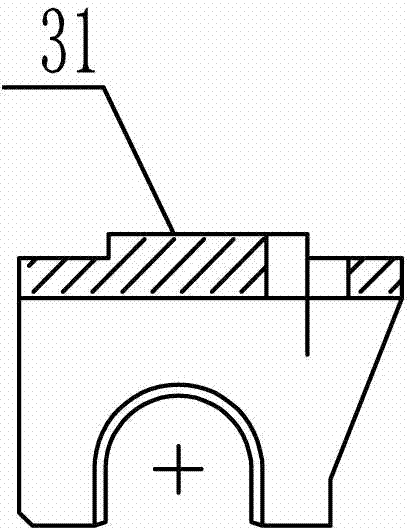

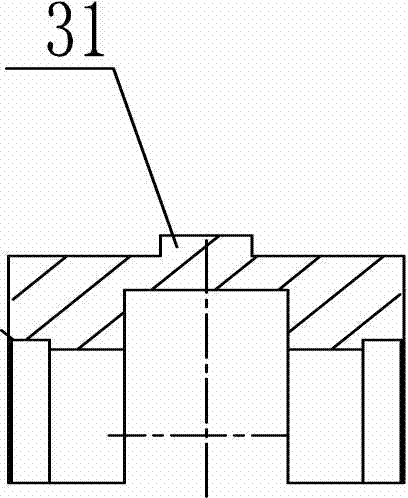

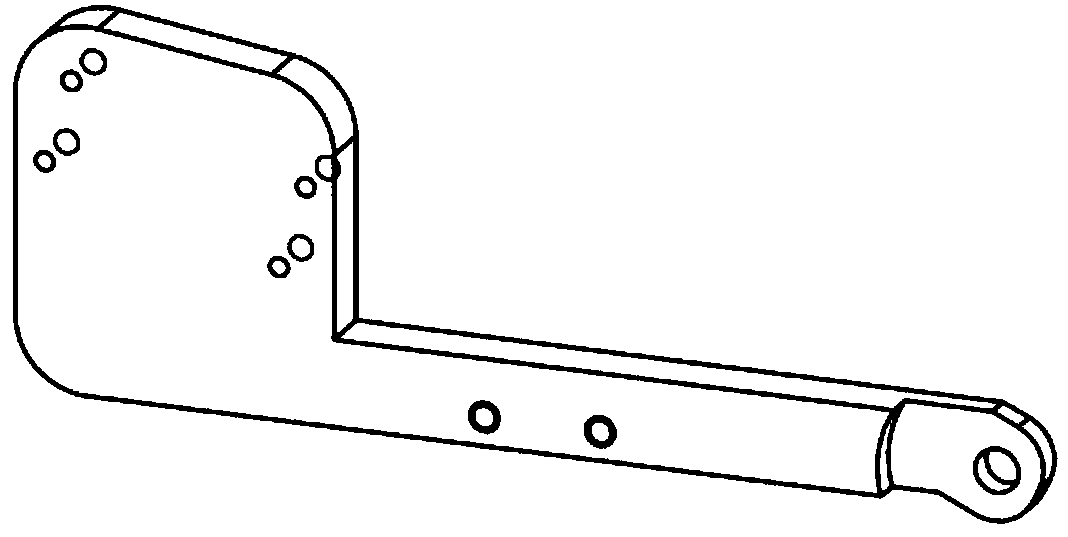

Lever type pneumatic cradle of roving machine

InactiveCN103114356AChange the level of oppressionChange the pressure valueDrafting machinesPressure transmissionEngineering

The invention discloses a lever type pneumatic cradle of a roving machine. The lever type pneumatic cradle of the roving machine comprises a cradle housing, a handle and a cradle holding seat, wherein the cradle housing, the handle and the cradle holding seat are connected with one another in a hinged mode, a pressure transmission crank is connected with the cradle holding seat in a hinged mode through a crank pin, a pressure pin sleeve at the lower end of the handle is connected in a pressure groove in the front end of the pressure transmission crank in a clamped mode, an adjusting screw rod is mounted at the rear end of the pressure transmission crank through a first internally threaded hole, an inner groove body is mounted on the cradle housing through a connecting pin and a groove body pin hole, each of two pressure dispersing adjusting seats is mounted on the inner groove body through an adjusting pin, an adjusting pin hole and an adjusting mounting hole of the pressure dispersing adjusting seat, two upper roller holding seats are respectively mounted in sliding grooves of each pressure dispersing adjusting seat, and the upper roller holding seats can move in the sliding grooves and can be positioned in the sliding grooves through bolts. According to the lever type pneumatic cradle of the roving machine, the lever principle is fully used, stepless pressure adjustment and rapid pressure adjustment can be realized in the lever type pneumatic cradle of the roving machine, and pressure is enabled to be lasting and constant.

Owner:张家港双帆纺织器械有限公司

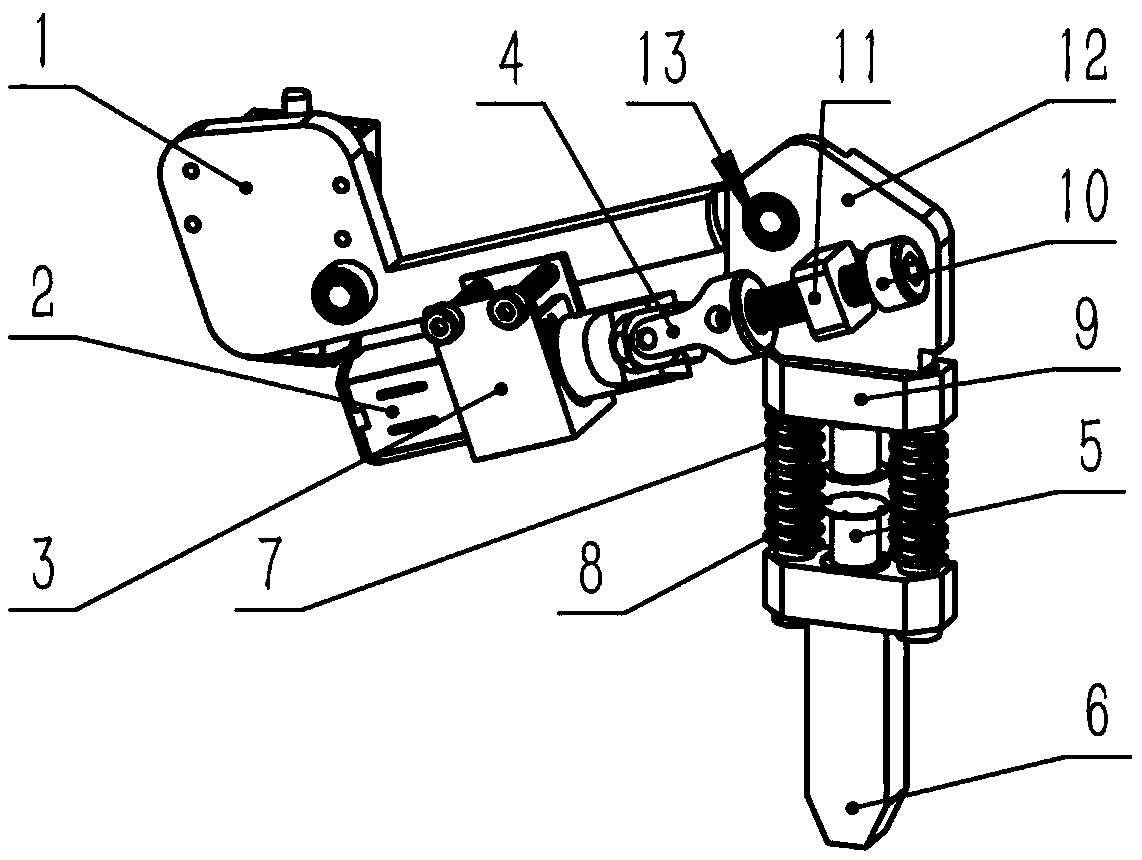

A semi-automatic control of the support stiffness of a machine leg

InactiveCN108890626AActively adjustable support stiffnessChange intensityProgramme-controlled manipulatorTerrainSemi active

The invention discloses a semi-automatic regulating machine leg for supporting rigidity, comprising a hip joint plate, a knee joint plate and a supporting leg. The hip joint plate connected with the robot main body comprises an integrally arranged mounting plate and a connecting rod. The mounting plate is fixedly provided with a hip joint motor and the connecting rod is fixedly provided with a knee joint motor. The end of the connecting rod of the hip joint plate and the knee joint plate is movably connected through the knee joint rolling bearing, and the output shaft of the knee joint motor is movably connected with the knee joint plate and exerts driving force; The bottom end of the knee joint plate is fixedly connected to the support leg. The support rigidity of the invention is semi-automatically regulated by a machine leg, By changing the number of layers of the coil and adjusting the magnitude of the power supply current, the strength of the magnetic field generated by the electromagnetic coil and the distribution of the magnetic induction lines can be changed, thereby changing the interaction force between the electromagnetic coils. Furthermore, according to the load size and the task terrain requirements, the semi-active adjustable support stiffness of the machine leg can be realized.

Owner:SHANGHAI UNIV

Ultra-bright polyester filament yarn for cross-stitch embroidery and preparation method of ultra-bright polyester filament yarn

ActiveCN109750371AChange interaction forceImprove dyeing effectMelt spinning methodsMonocomponent polyesters artificial filamentEsterification reactionTerephthalic acid

The invention relates to ultra-bright polyester filament yarn for cross-stitch embroidery and a preparation method of the ultra-bright polyester filament yarn. The preparation method comprises the step that modified polyester fully drawn yarn (FDY), namely the ultra-bright polyester filament yarn for the cross-stitch embroidery, is prepared from a modified polyester melt according to an FDY process through a triangular or linear spinneret plate,; and a preparation method of modified polyester comprises the steps that terephthalic acid, ethanediol, dibasic acid with a tertiary butyl side group,hexanediol with a tertiary butyl side group and 2,5,6,6-tetramethyl-2,5-heptandiol are evenly mixed, and then an esterification reaction and a polycondensation reaction are conducted successively. The dye-uptake of the prepared ultra-bright polyester filament yarn for the cross-stitch embroidery at the temperature of 123 DEG C is 86.3-89.2%, the K / S value is 21.15-24.6, the soaping-resistant color fastness reaches the fifth level, the dry friction fastness reaches the fifth level, and the wet friction fastness reaches the fourth level. The preparation method is simple in process, and the prepared ultra-bright polyester filament yarn for the cross-stitch embroidery is good in dyeing performance.

Owner:JIANGSU HENGLI CHEM FIBER

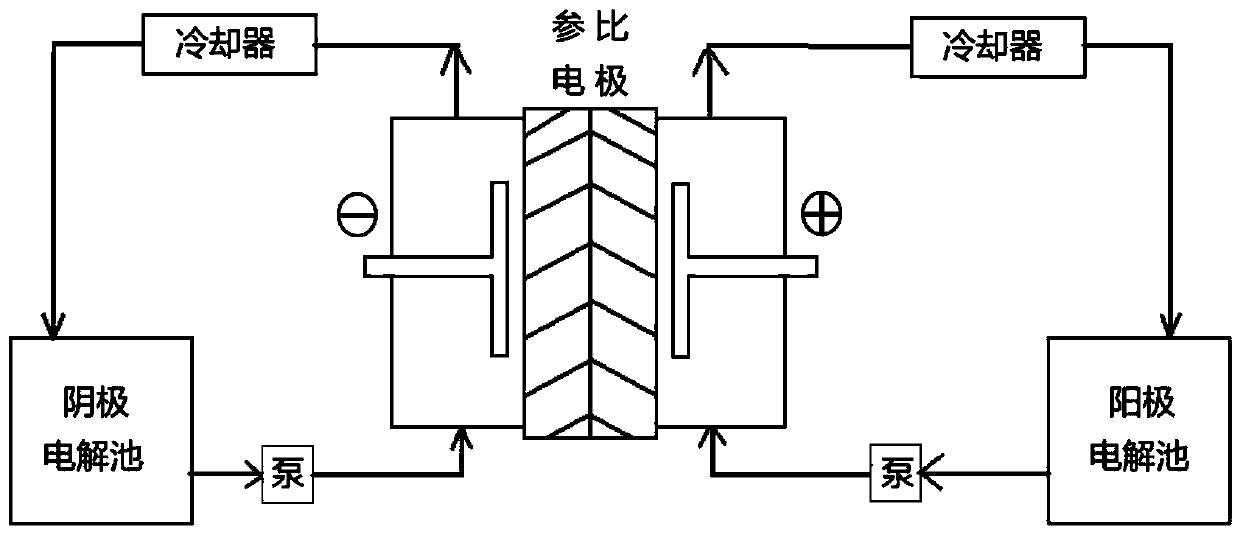

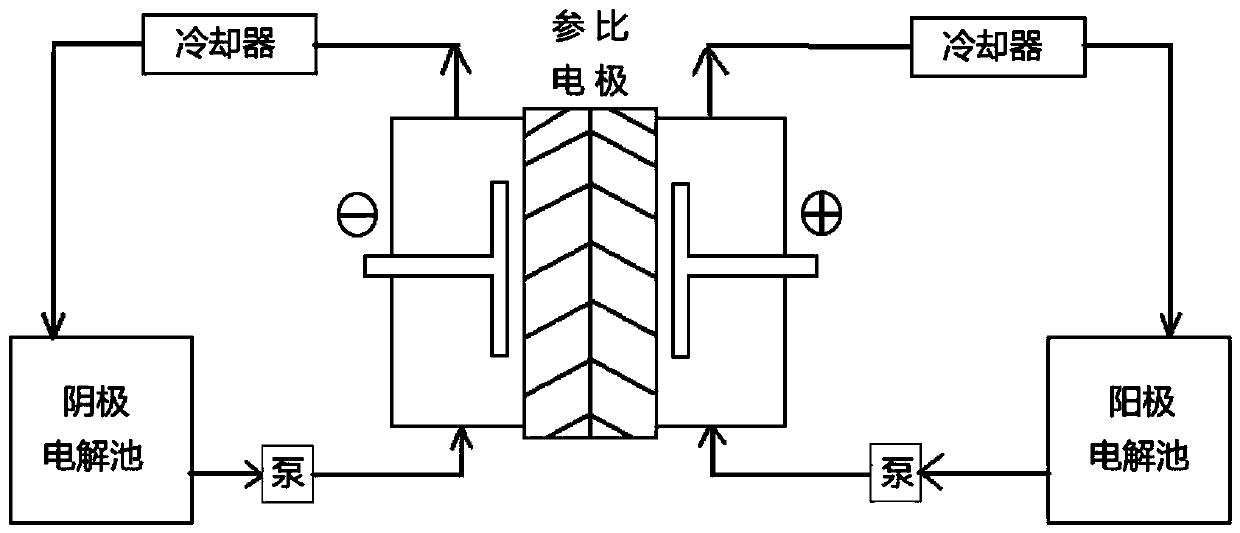

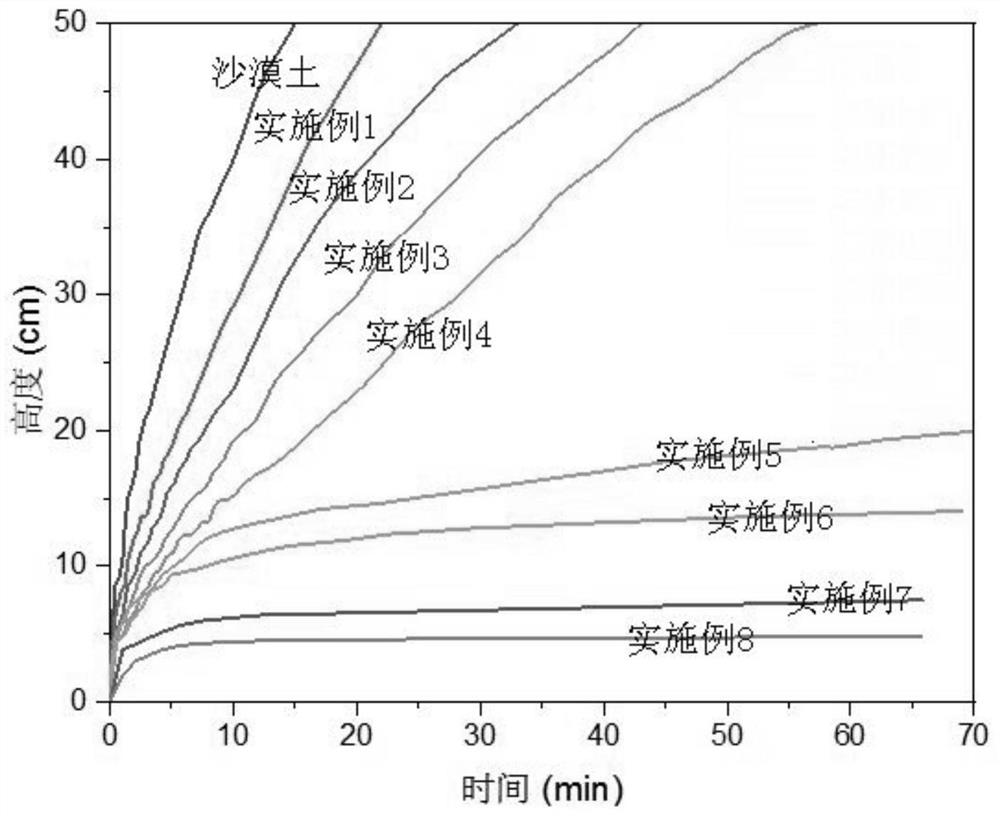

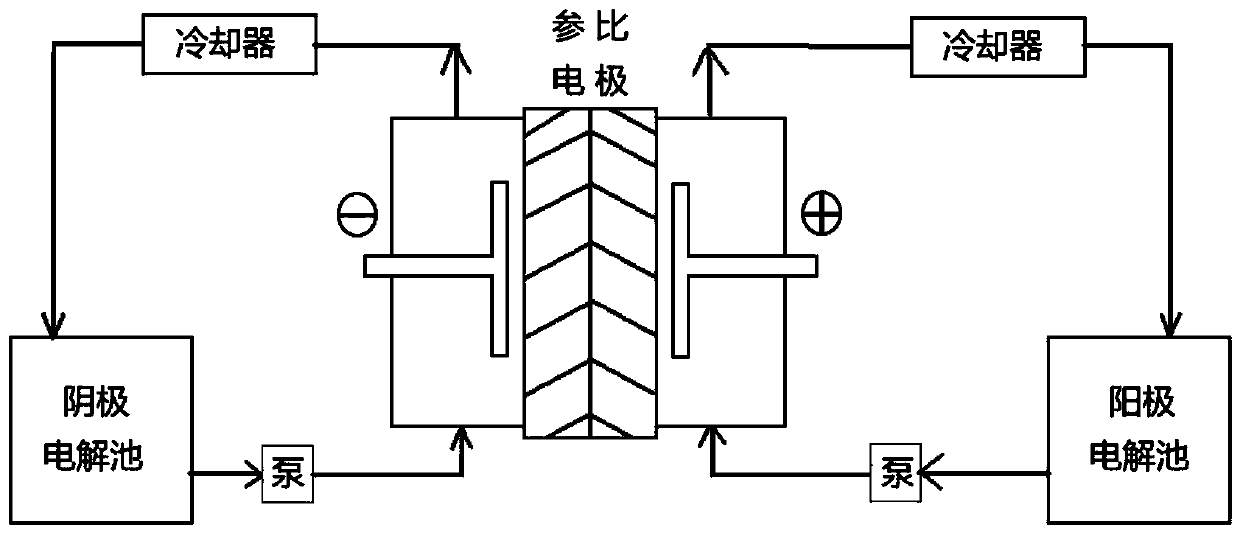

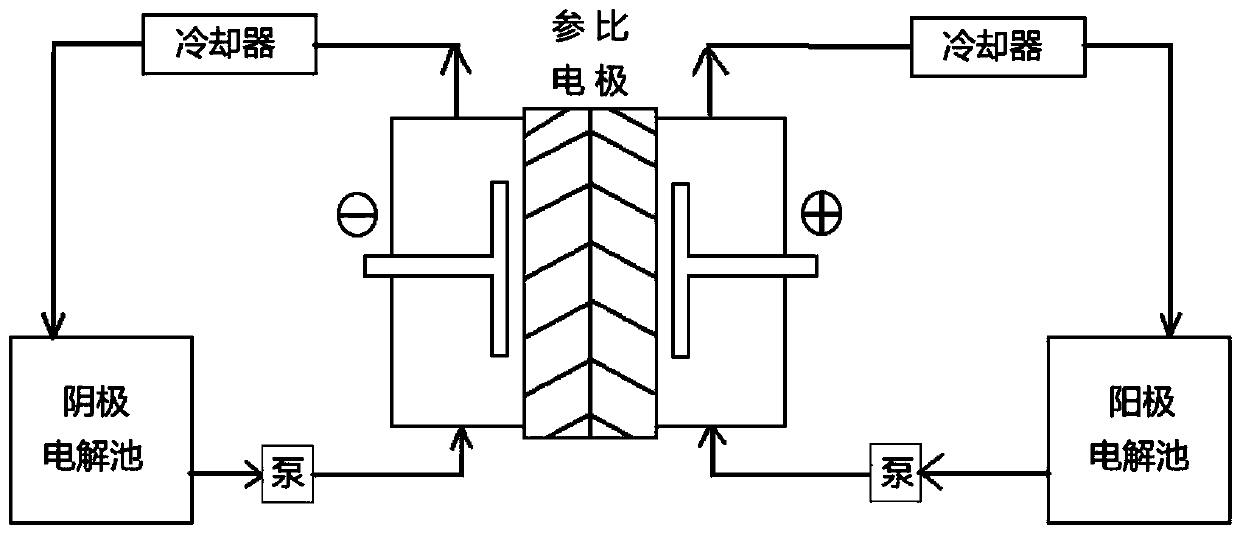

Method for regulating and controlling water retention capacity of porous material and product thereof

PendingCN113004901ATargeted regulation of permeabilityTune electrochemical propertiesOther chemical processesOrganic fertilisersSoil scienceAlkali soil

The invention relates to a method for regulating and controlling the water retention capacity of a porous material and a product thereof, and belongs to the technical field of porous medium permeability regulation and control. The pore condition of the porous material is adjusted based on the interaction force among particles in the porous medium, so that the water retention capacity of the porous material is improved. The method mainly comprises the following steps of: adding any one of saline-alkali soil with the salt content of more than or equal to 1 percent, a mixture of the saline-alkali soil with the salt content of more than or equal to 1 percent and clay minerals or a mixture of the saline-alkali soil with the salt content of more than or equal to 1 percent, the clay minerals and anionic polyacrylamide into a matrix material of a porous medium; the water retention capacity of the porous material can be regulated and controlled by stirring and uniformly mixing, and a water retention layer of any depth of the porous medium is constructed according to actual requirements.

Owner:SOUTHWEST UNIVERSITY

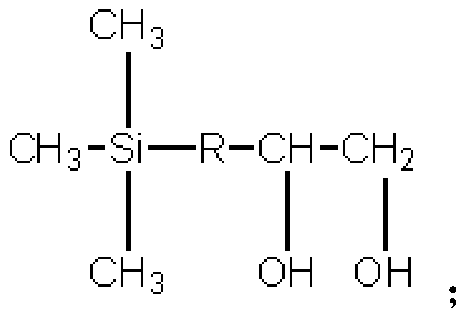

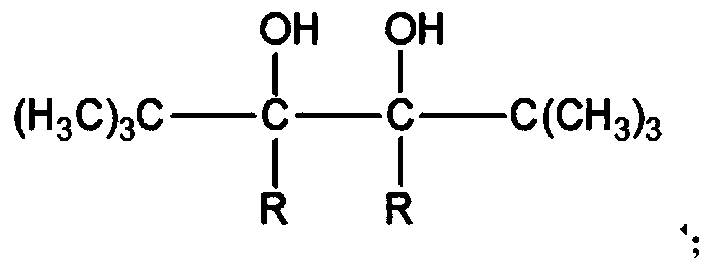

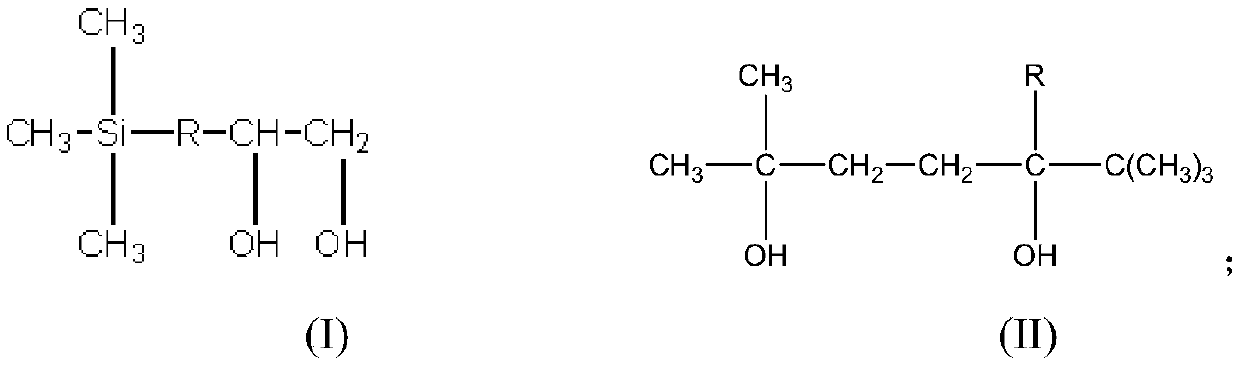

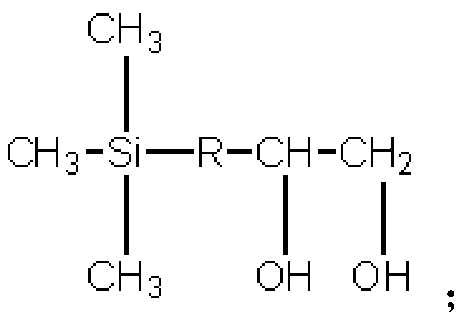

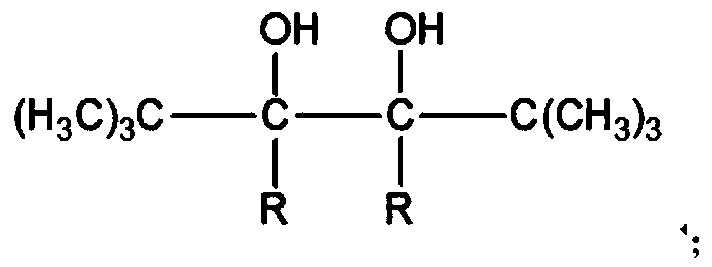

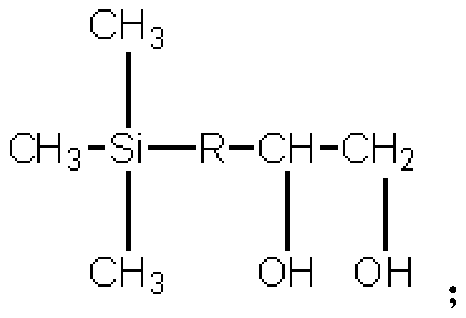

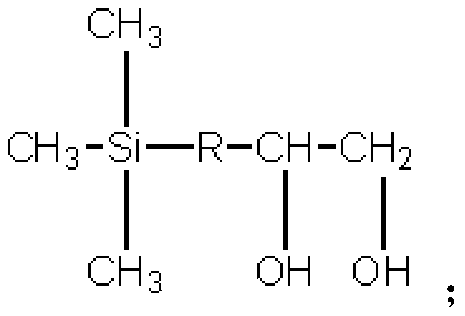

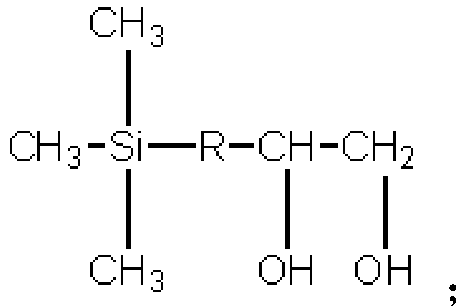

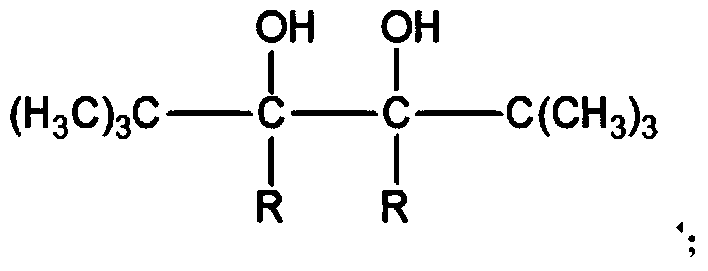

Dihydric alcohol modified polyester fibers with trimethylsilyl lateral groups and preparation method thereof

ActiveCN109722739AIncrease the free volume of spaceChange interaction forceMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterChemistry

The invention relates to dihydric alcohol modified polyester fibers with trimethylsilyl lateral groups and a preparation method thereof. Dihydric alcohol modified polyester melts with the trimethylsilyl lateral groups are metered, extruded out through a spinneret plate, cooled, oiled and wound to prepare the dihydric alcohol modified polyester fibers with trimethylsilyl lateral groups, dihydric alcohol chain segments with trimethylsilyl lateral groups are introduced into molecular chains of dihydric alcohol modified polyester with trimethylsilyl lateral groups, and the structural formula of the chain segments is shown in the specification, wherein R is -CH2- or -CH(CH3)-or -C[(CH3)2]-, and doping modification Bi2O3 powder and doping modification Sb2O3 powder are dispersed in the dihydric alcohol modified polyester with trimethylsilyl lateral groups. The method is simple in technology, and the dihydric alcohol modified polyester fibers with trimethylsilyl lateral groups is good in dyeing performance, high in natural degrading efficiency and quite good in popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Cleaning method for micron-sized flake silver powder

PendingCN114226745AGood dispersionLower impedanceTransportation and packagingMetal-working apparatusFree energiesCleaning methods

The invention provides a micron-sized flake silver powder cleaning method which comprises the following steps: mixing silver nitrate, a reducing agent and a water repellent agent, and reacting to obtain a reaction product; dehydrating the reaction product until the mass content of silver powder is greater than or equal to 95%, and adding ethanol for slurrying treatment; and adding an iodine compound under an ultrasonic condition, shearing and washing at 1500-2500rpm, carrying out solid-liquid separation, and drying to obtain the micron-sized flake silver powder. According to the method, the hydrophobic agent such as oleic acid is used for conducting hydrophobic treatment on the surface of the silver powder in the reaction process, the interaction force between the silver powder is changed, the surface free energy of silver powder agglomeration is washed and broken in a high-speed shearing mode, the dispersity of the silver powder in an oily system is reasonably improved, and the impedance of the silver powder is reduced. The impedance of the silver powder obtained by cleaning through the cleaning method provided by the invention can be reduced by 10-20%; and the impedance reaches 170 ohms.

Owner:江西贝特利新材料有限公司

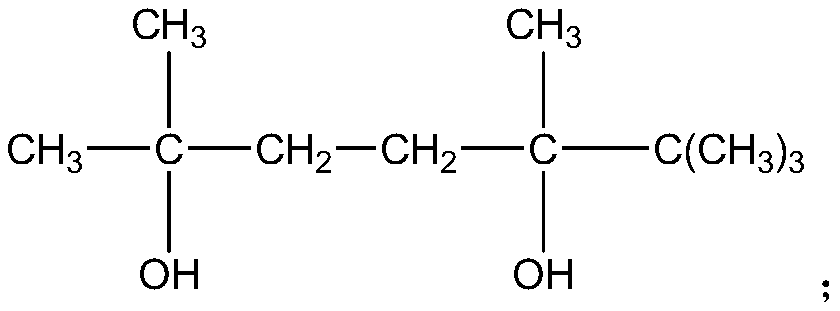

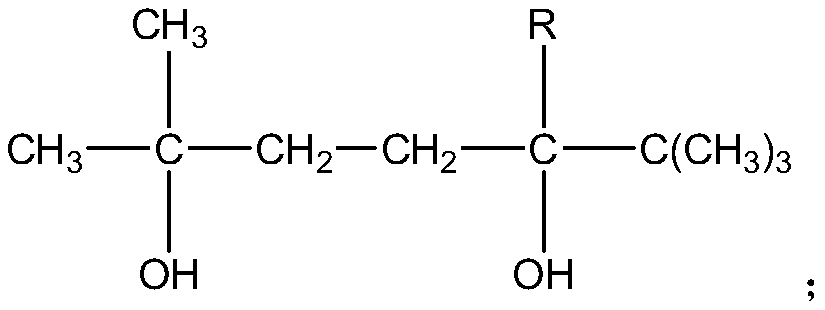

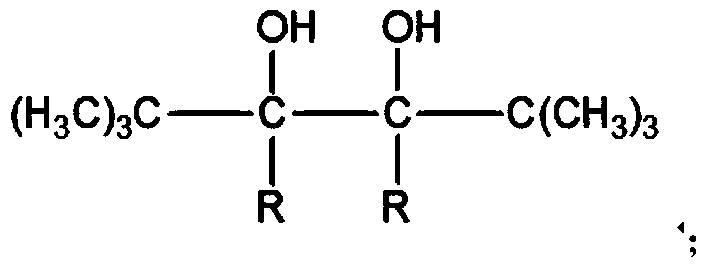

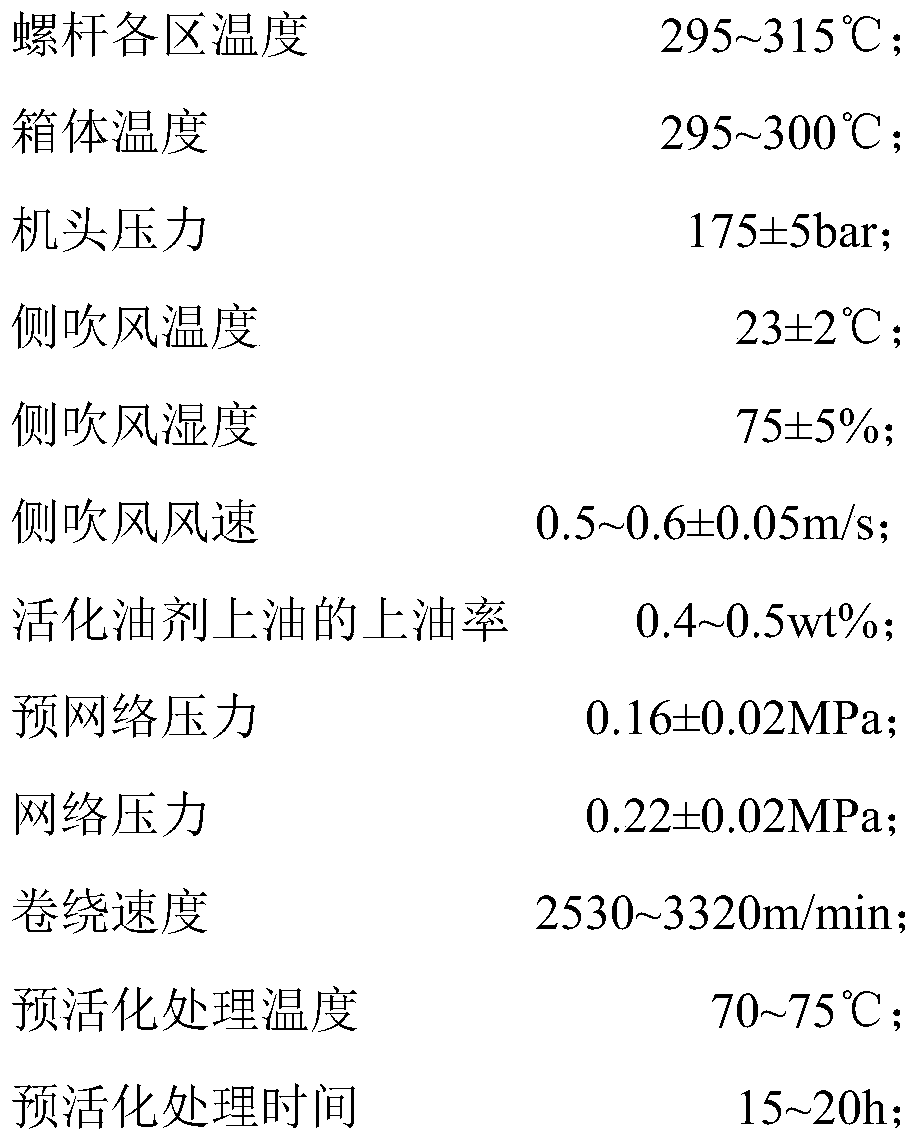

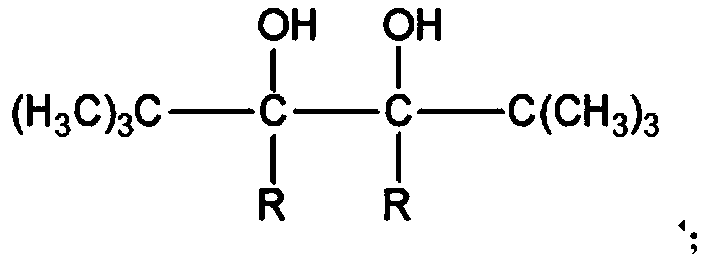

High-strength activated polyester industrial yarn and preparation method thereof

ActiveCN109750373AChange interaction forceImprove efficiencyMonocomponent polyesters artificial filamentArtifical filament manufactureYarnStructural formula

The invention relates to high-strength activated polyester industrial yarn and a preparation method thereof. The preparation method comprises the steps: firstly, terephthalic acid, ethylene glycol andethylene glycol with tertiary butyl side groups are evenly mixed, and then an esterification reaction and a polycondensation reaction are carried out successively to prepare modified polyester; and then the modified polyester is subjected to solid phase polycondensation tackifying, fusing, metering, extruding, cooling, oil applying, stretching, heat setting, activating oil agent applying, windingand pre-activating treatment, and then the high-strength activated polyester industrial yarn is prepared. The structural formula of the ethylene glycol with the tertiary butyl side groups is as followings: (please see the specifications for the structural formula), wherein R in the formula is -H or -CH2CH3 or -C(CH3)3. The activating efficiency of the finally prepared high-strength activated polyester industrial yarn is high; the preparation method is simple, the polyester is modified through the ethylene glycol with the tertiary butyl side groups, the using efficiency of an activating agentis improved, the activating temperature is lowered, the activating time is shortened, and the influences of activating on mechanical properties of polyester fibers are lowered; and a prepared productis good in activating effect and mechanical property.

Owner:JIANGSU HENGLI CHEM FIBER

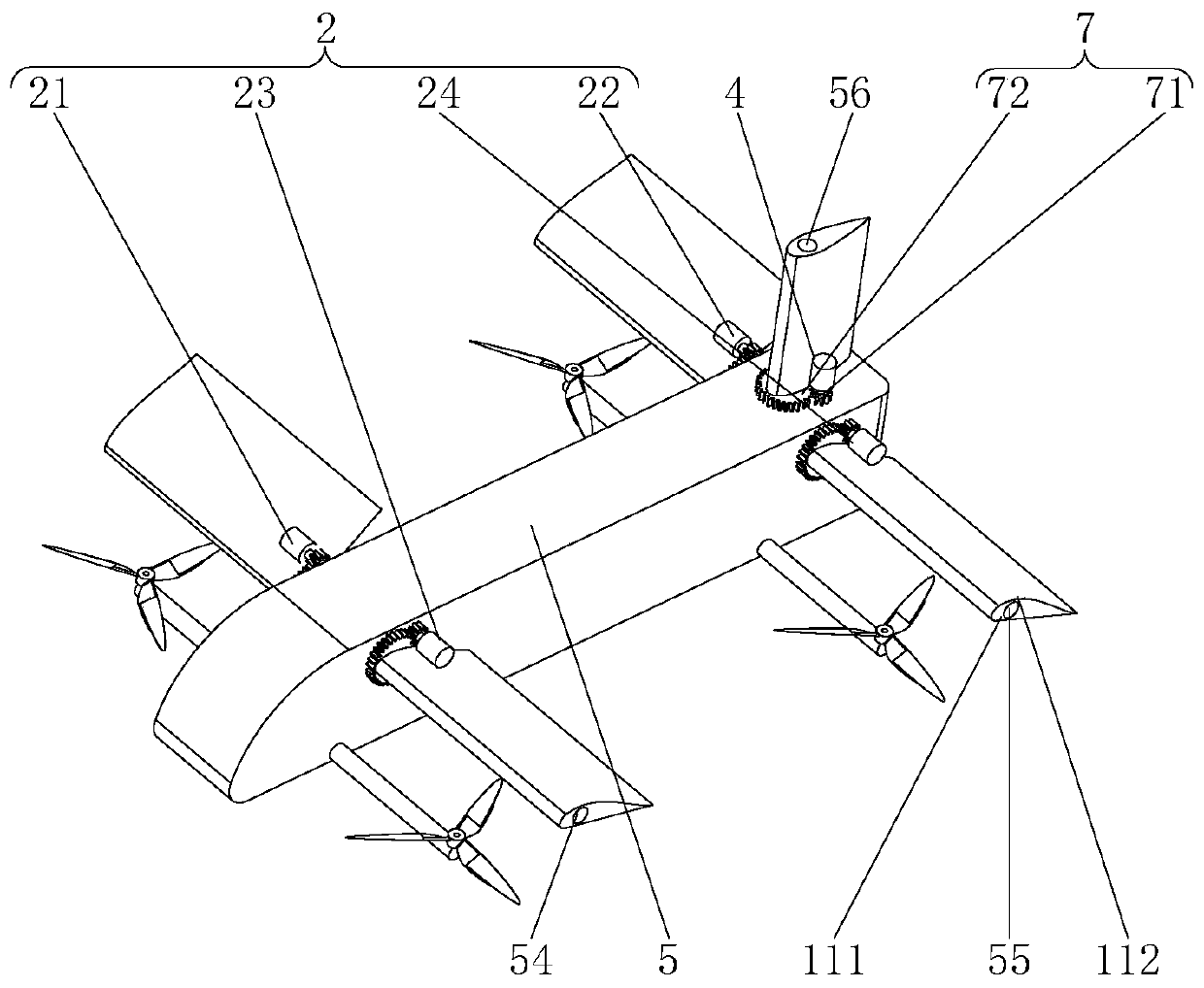

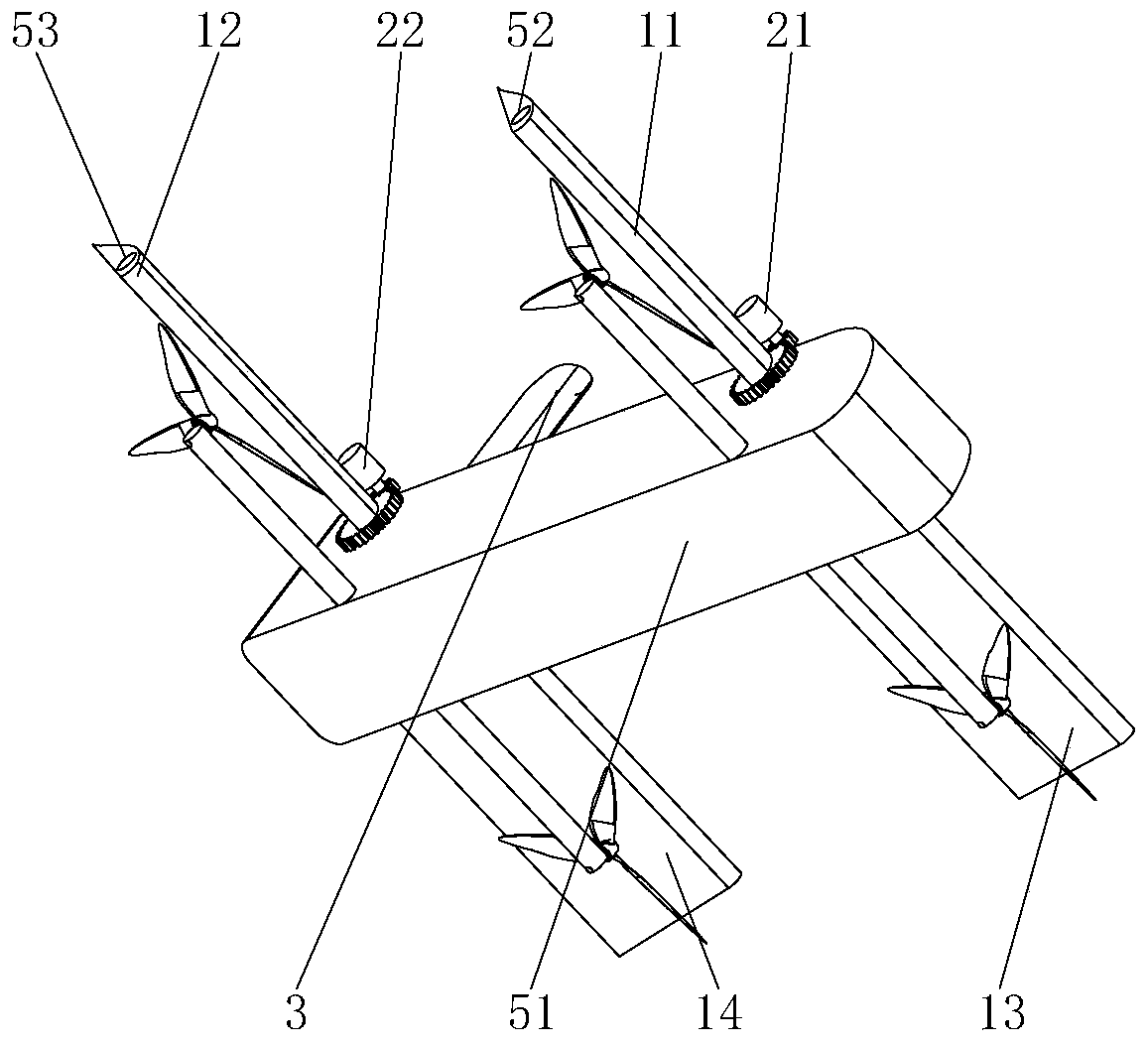

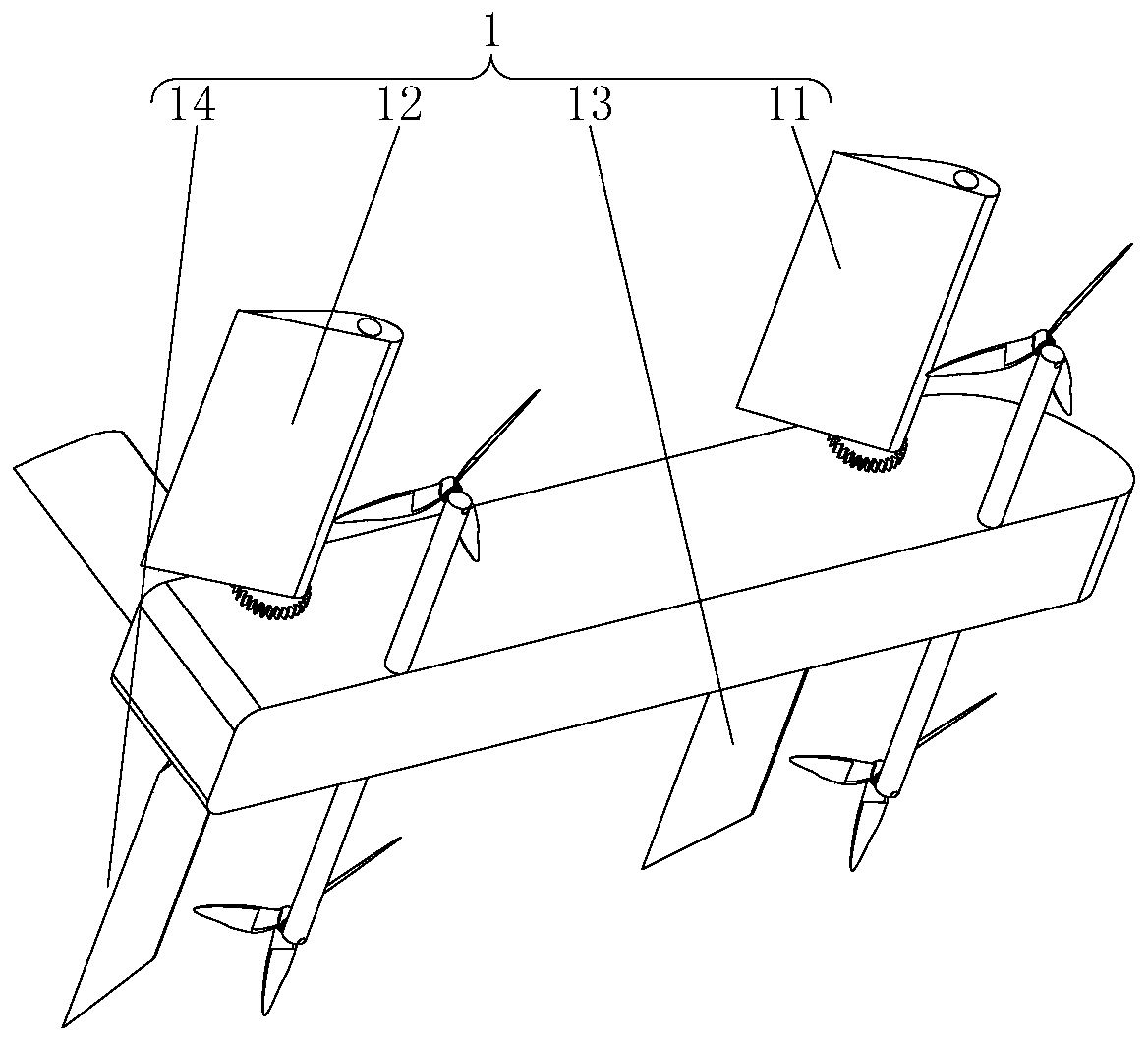

Multi-rotor aircraft auxiliary flight device

The embodiment of the invention discloses a multi-rotor aircraft auxiliary flight device, and relates to the technical field of aircrafts. The device comprises a first auxiliary wing component, a first driving component, a second auxiliary wing, a second driving component and a unit body; the first auxiliary wing component, the first driving component, the second auxiliary wing and the second driving component are all arranged on the unit body, the first driving component is connected with the first auxiliary wing component through a first regulating component, the axis direction of the firstauxiliary wing component is in the horizontal plane, the second driving component is connected with the second auxiliary wing through a second regulating component, and the axis direction of the second auxiliary wing is in the vertical plane; by additionally arranging the device on the aircraft or an unmanned aerial vehicle, the flight attitude is adjusted at different flight stages of the aircraft or the unmanned aerial vehicle, the duration of flight and the service life of an engine are prolonged, and the failure rate is lowered.

Owner:李明珠

Viscose imitated polyester filament yarn and preparation method thereof

ActiveCN109735918AIncrease the free volume of spaceIncrease the void free volumeArtificial filament heat treatmentMonocomponent copolyesters artificial filamentViscoseAdipic acid

The invention relates to a viscose imitated polyester filament yarn and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing terephthalic acid, ethyleneglycol, a binary acid with a tert-butyl side group and hexanediol with a tert-butyl side group, and sequentially carrying out an esterification reaction and a polycondensation reaction to prepare modified polyester; preparing modified polyester POY yarns from modified polyester melt according to a POY process by adopting a triangular special-shaped spinneret plate; and finally, preparing the viscose imitated polyester filament yarns from the modified polyester POY yarns according to a DTY process. The binary acid with the tert-butyl side group is 5-tert-butyl-1,3-phthalic acid, 2-tert-butyl-1,6-adipic acid, 3-tert-butyl-1,6-adipic acid or 2,5-tert-butyl-1,6-adipic acid; and the prepared viscose imitated polyester filament yarn has the dye-uptake of 87.3-91.2% under the temperature condition of 125 DEG C, also has the K / S value of 22.15-25.4, and is high in color fastness. The preparation method disclosed by the invention is simple in process, and the prepared product is excellent in dyeing property.

Owner:JIANGSU HENGLI CHEM FIBER

An electromagnetic high-precision ultra-micro force generating device

InactiveCN107640736BChange interaction forceChange intensityTelevision system detailsForce measurement by measuring magnetic property varationCantilevered beamElectromagnetic shielding

The invention discloses an electromagnetic-type generation device with high precision and super-micro force. The device comprises an annular end cover, a cantilever beam component and a base body which are connected from top to bottom in sequence, the base body is arranged to be in a cylindrical shape with an axial cavity, an annular groove is formed in the outer wall of the base body along the circumference, and a winding coil winds the interior of the annular groove; the cantilever beam component comprises an annular fixing base, a cantilever is connected to the inner circle of the fixing base, and a mounting sheet is connected to the cantilever; the fixing base, the cantilever and the mounting sheet are arranged to be an integrated structure, and a columnar permanent magnet is arrangedon the bottom of the mounting sheet. According to the electromagnetic-type generation device, the micro-Newton level and nano-Newton level applied force can be precisely generated, and the device hasthe advantages of high precision, high response speed and the like and is suitable for a system driven by precise super-micro force.

Owner:TIANJIN UNIV

Preparation method of polyester sun-shading cloth

ActiveCN109930231AHigh tensile strengthHigh peel strengthArtificial filament heat treatmentMelt spinning methodsYarnPolyester resin

The invention relates to a preparation method of polyester sun-shading cloth. The preparation method comprises the following steps: warping, weaving and calendering modified polyester industrial yarnsto be adhered with a PVC film to obtain the polyester sun-shading cloth, wherein the modified polyester industrial yarns are prepared by carrying out solid-phase polycondensation and tackifying, melting, metering, extruding, cooling, oiling, stretching, heat setting, relaxation heat treatment and winding on a modified polyester melt; and the preparation method of the modified polyester before thesolid-phase polycondensation and tackifying comprises the following steps : mixing terephthalic acid, ethylene glycol, 2, 2, 3, 4, 5, 5-5- hexamethyl- 3, 4-hexanediol and the doped modified Sb2O3 powder are uniformly mixed, esterification reaction and polycondensation reaction are carried out in sequence, and relaxation heat treatment means that the modified polyester industrial yarn passes through a space of 200-240 DEG C when the overfeeding rate of winding is 3.0-5.0%. The preparation method is simple, the cost is low, and the prepared polyester sun-shading cloth is high in quality, good in tensile strength, high in peel strength, low in thermal shrinkage and wide in application range.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of novel composite plate and preparation method thereof

ActiveCN104175660BSolve severe deformationLow costSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

A fire hose dewatering and rewinding device

The invention relates to the technical field of fire hoses, and discloses a fire hose dewatering and winding device. The fire hose dewatering and winding device comprises a bottom plate and a shell; awinding disc is arranged inside the shell; a fixed hole is formed in the winding disc; a fixed block is arranged at the lower part of the fixed hole; a water hose is clamped between the fixed block and the winding disc; a movable frame is arranged in the shell; a friction roller is fixedly connected to the movable frame; a fixed pulley is fixedly connected to the side surface of the movable frame; a spring is fixedly connected between the movable frame and the shell; a lock chain is fixedly connected to the bottom plate; one end of the lock chain bypasses the fixed pulley; a slideway is fixedly connected to the right part of the shell; and a pressing rod is arranged at the left end of the slideway. According to the fire hose dewatering and winding device, water in the water hose is extruded out under the action of impact of six corners of the winding disc on the water hose and the inclined slide way, and the device has the advantages that the water hose can be dewatered and wound anddeicing slag treatment can be carried out.

Owner:南通亚龙消防器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com