An electromagnetic high-precision ultra-micro force generating device

A generation device, high-precision technology, used in measurement devices, piezoelectric effect/electrostrictive or magnetostrictive motors, components of TV systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

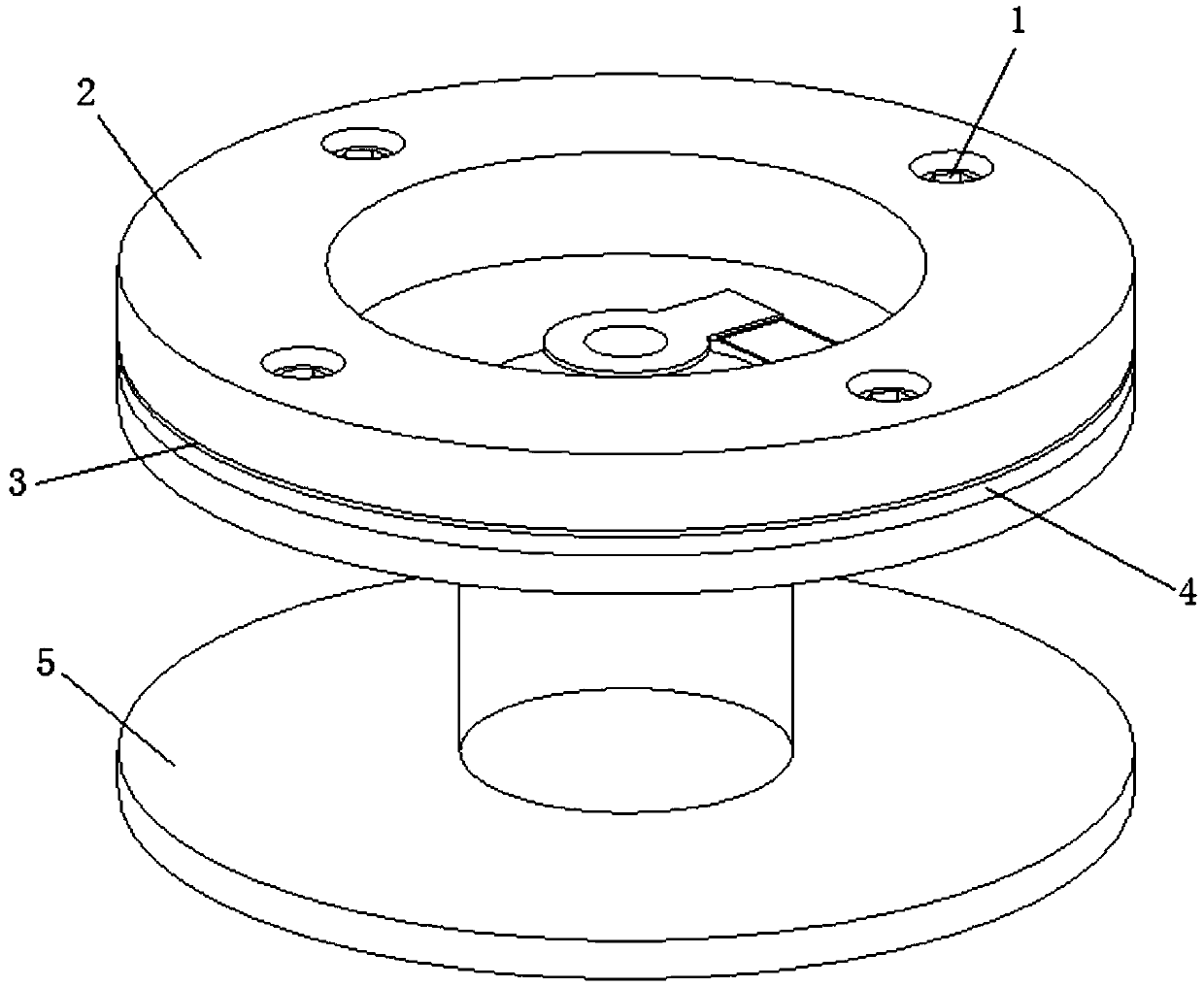

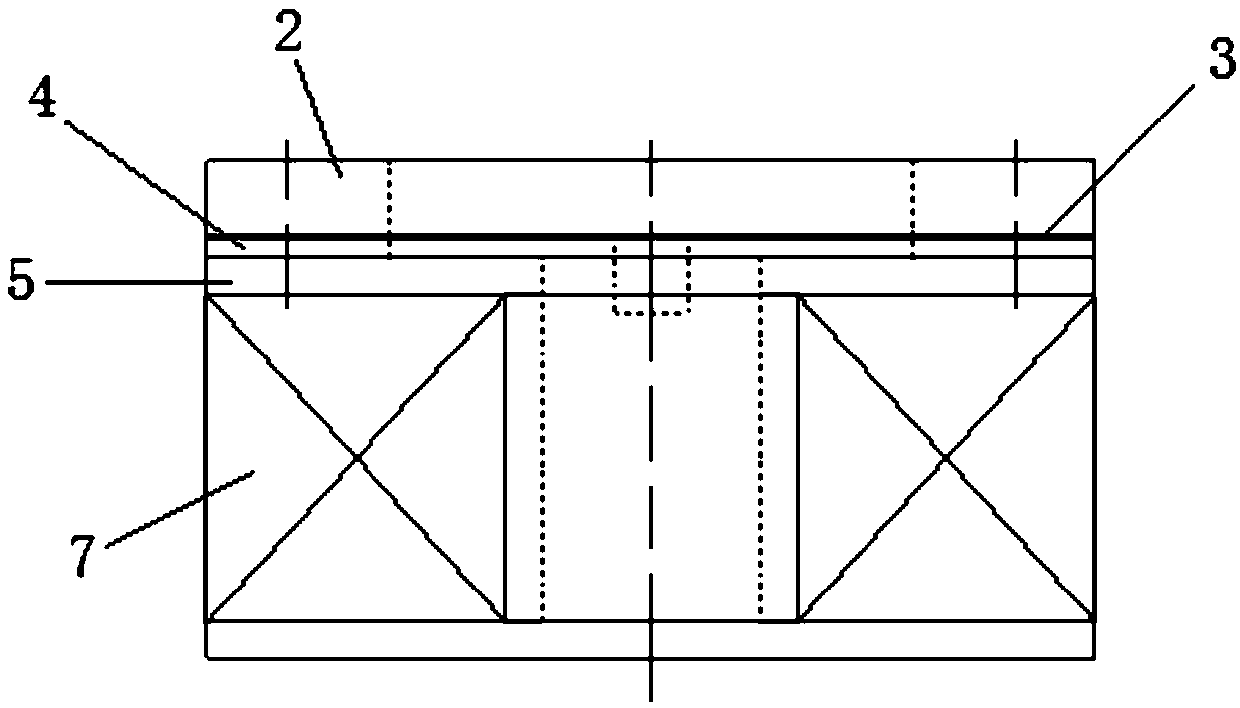

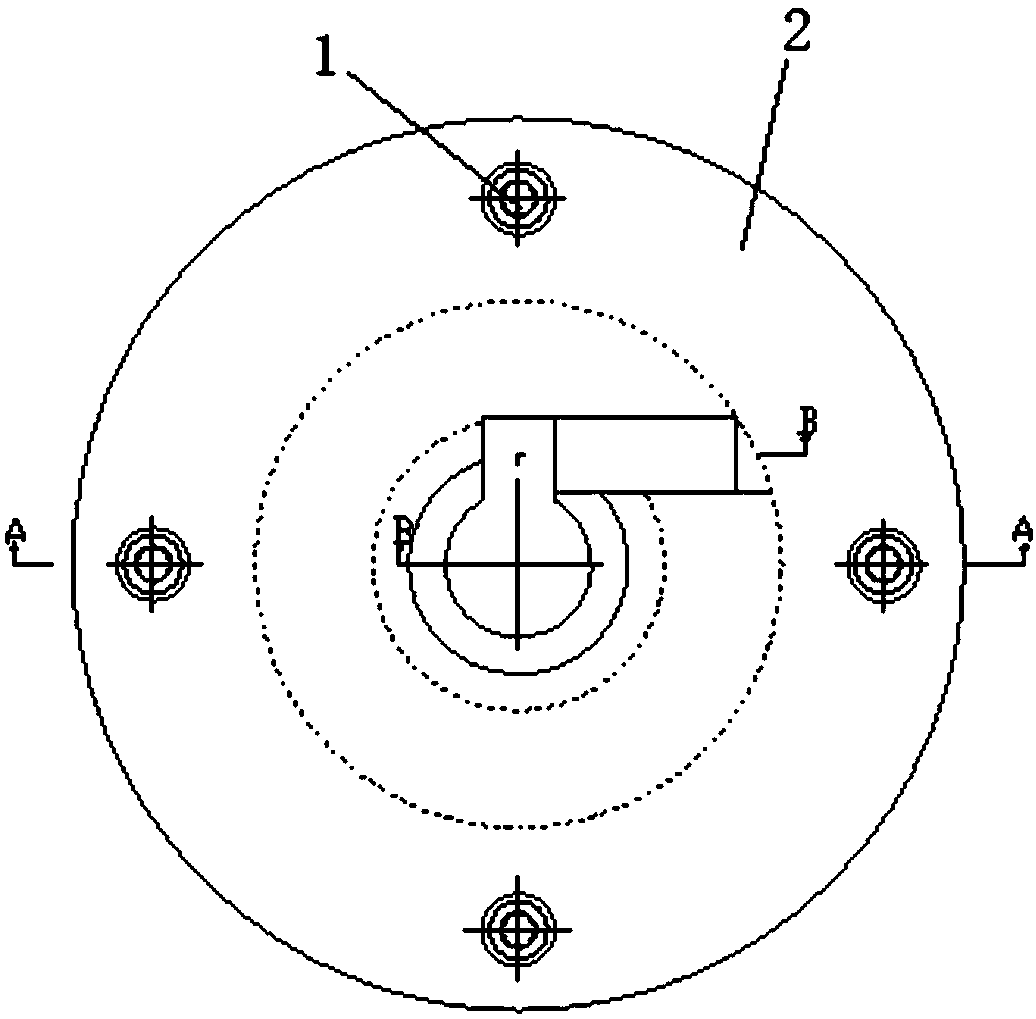

[0024] Such as Figure 1 to Figure 6 As shown, the electromagnetic high-precision ultra-micro force generating device of the present invention includes an end cover 2, a cantilever beam member 3, a gasket 4 and a base 5 connected sequentially from top to bottom, and the end cover 2, the cantilever beam member 3. The gasket 4 and the base body 5 are arranged along the coaxial line, and the end cover 2, the cantilever beam member 3, the gasket 4 and the base body 5 are all provided with threaded holes, and are fixed by countersunk bolts 1 arranged in the axial direction connection, can be set to four.

[0025] Both the end cap 2 and the spacer 4 are arranged in an annular shape, and the spacer 4 separates the cantilever beam member 3 from the base body 5 by a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com