Method for preparing light tent cloth

A tent cloth, light technology, applied in the field of polyester fiber, can solve the problems of high heat shrinkage rate of tent cloth, difficult to meet the requirements of use, etc., to achieve the effect of reducing shrinkage rate, improving adhesion, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A kind of preparation method of light tent cloth, concrete steps are as follows:

[0063] (1) prepare modified polyester;

[0064] (1.1) Esterification reaction;

[0065] Prepare a slurry of terephthalic acid, ethylene glycol and 3-trimethylsilyl-1,2-propanediol with a molar ratio of 1:1.2:0.03, add antimony trioxide, titanium dioxide and triphenyl phosphate and mix evenly, The esterification reaction is carried out under pressure in a nitrogen atmosphere, the pressurized pressure is 0.1MPa, and the temperature of the esterification reaction is 250°C. When the amount of water distilled out in the esterification reaction reaches 93% of the theoretical value, it is the end point of the esterification reaction. The additions of antimony trioxide, titanium dioxide and triphenyl phosphate are respectively 0.03wt%, 0.20wt% and 0.02wt% of the terephthalic acid addition;

[0066] (1.2) polycondensation reaction;

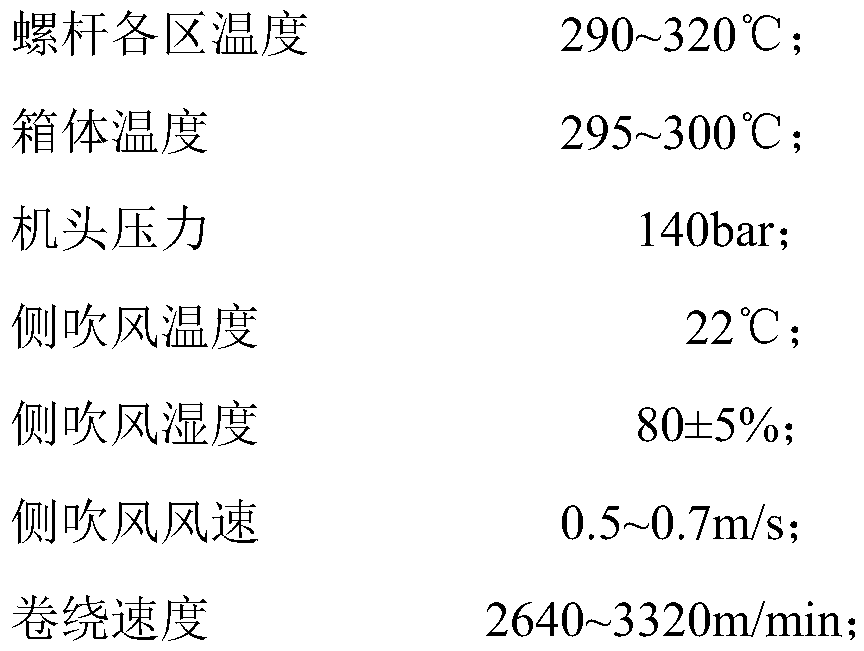

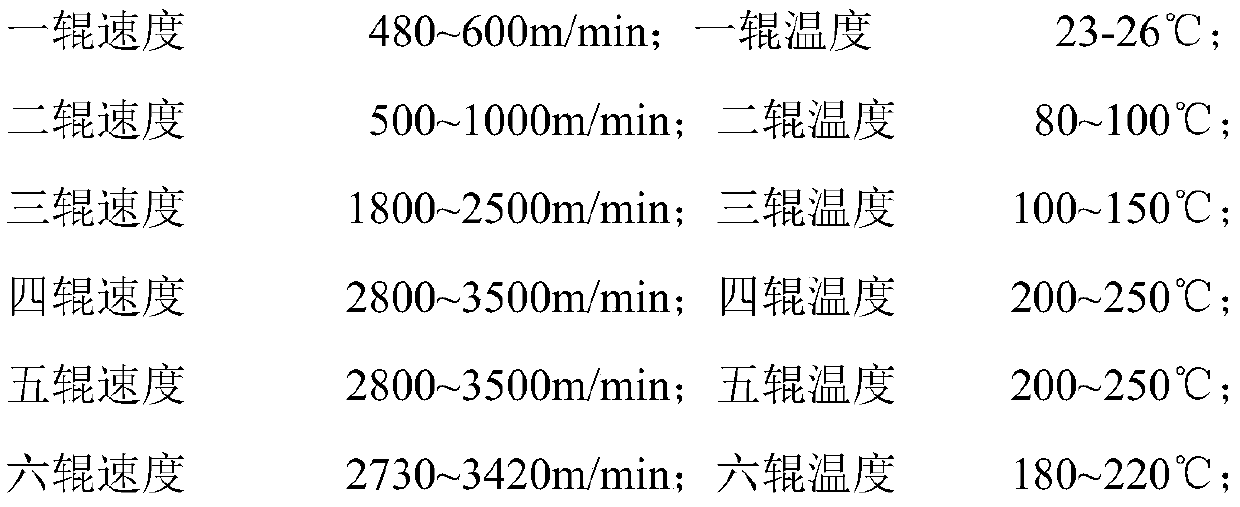

[0067] After the esterification reaction is over, start the p...

Embodiment 2

[0090] A kind of preparation method of light tent cloth, concrete steps are as follows:

[0091] (1) prepare modified polyester;

[0092] (1.1) Preparation of 3-trimethylsilyl-3-methyl-1,2-propanediol;

[0093] (1.1.1) Mix 3-trimethylsilyl-3-methylpropene, peracetic acid and dichloromethane at a molar ratio of 1:5:10, and react at a temperature of 35°C for 5 hours with stirring , the solvent is removed after the reaction, and trimethylsilylpropylene epoxide is obtained through purification and refinement;

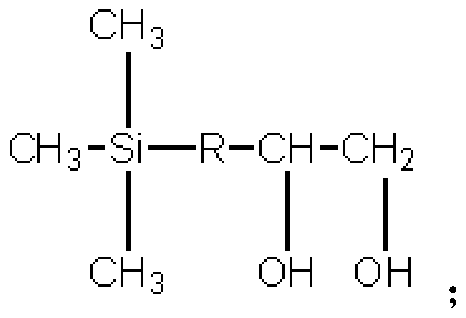

[0094] (1.1.2) Mix water, concentrated sulfuric acid and trimethylsilyl propylene epoxide, heat it in a water bath to 80°C under stirring conditions, keep it warm for 10 minutes, cool to room temperature after the reaction, neutralize, distill, separate and purify Obtain 3-trimethylsilyl-3-methyl-1,2-propanediol as shown in formula (I), R in formula (I) is-CH(CH 3 )-, concentrated sulfuric acid is the sulfuric acid that mass concentration is 70%, when reaction starts, th...

Embodiment 3

[0111] A kind of preparation method of light tent cloth, concrete steps are as follows:

[0112] (1) prepare modified polyester;

[0113] (1.1) Preparation of 3-trimethylsilyl-3-methyl-1,2-propanediol;

[0114] (1.1.1) Mix 3-trimethylsilyl-3-methylpropene, peracetic acid and dichloromethane at a molar ratio of 1:10:15, and react at a temperature of 40°C for 8 hours with stirring , the solvent is removed after the reaction, and trimethylsilylpropylene epoxide is obtained through purification and refinement;

[0115] (1.1.2) Mix water, concentrated sulfuric acid and trimethylsilyl propylene epoxide, heat it in a water bath to 85°C under stirring conditions, keep it warm for 15 minutes, cool to room temperature after the reaction, neutralize, distill, separate and purify Obtain 3-trimethylsilyl-3-methyl-1,2-propanediol as shown in formula (I), R in formula (I) is-CH(CH 3 )-, concentrated sulfuric acid is the sulfuric acid that mass concentration is 70%, when reaction starts, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com