Ultra-bright polyester filament yarn for cross-stitch embroidery and preparation method of ultra-bright polyester filament yarn

A polyester filament and cross stitch technology, applied in the field of modified polyester fibers, can solve the problems of increased process complexity, high equipment requirements, lack of active groups, etc., to shorten the dyeing time, reduce dyeing temperature, and improve dyeing. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation method of super bright polyester filament for cross-stitching, the steps are as follows:

[0068] (1) prepare modified polyester;

[0069] (1.1) Preparation of 2,2,5,5-tetramethyl-3,4-hexanediol;

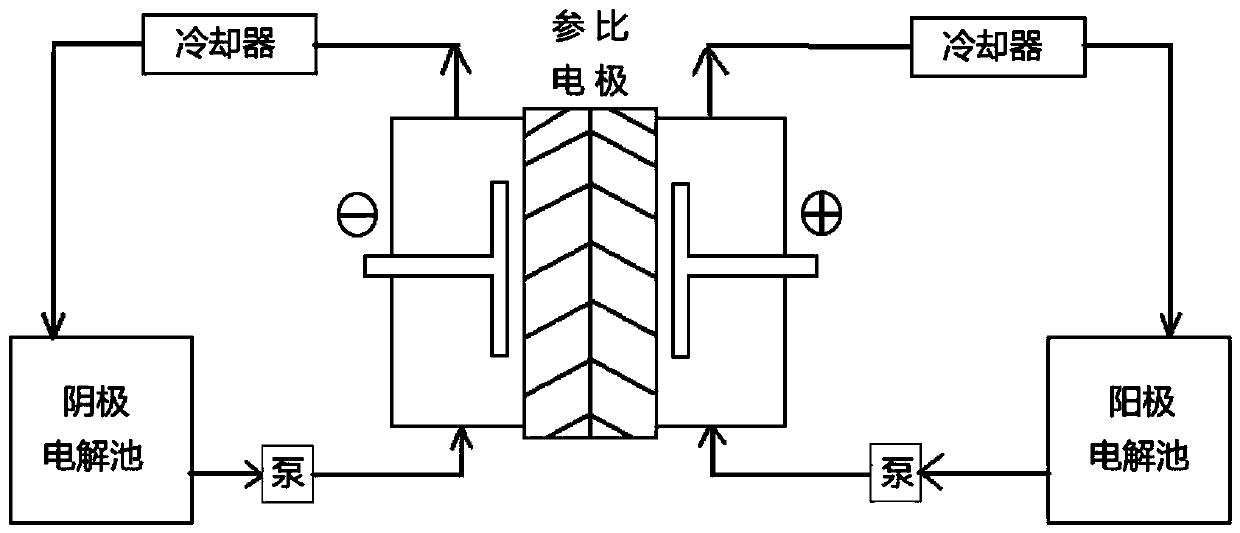

[0070] First, mix 2,2-methylpropanal solution with a concentration of 320g / L and dilute sulfuric acid solution with a concentration of 200g / L according to the ratio of 2,2-methylpropanal to sulfuric acid molar ratio of 1.5:1 In the cathodic electrolytic cell, then, the mixed solution is cooled to 12°C, followed by electrolytic reduction to a concentration of 9.5wt% of 2,2-methylpropanal, and finally cooled crystallization, separation and purification, the method used in the synthesis process The schematic diagram of the reaction apparatus is as figure 1 As shown, the reaction chemical equation is as follows:

[0071]

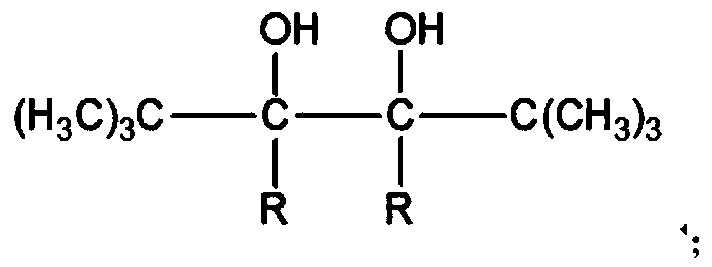

[0072] The structural formula of the prepared 2,2,5,5-tetramethyl-3,4-hexanediol is shown in formula (I), where R is -H;

[0073] (1.2) ...

Embodiment 2

[0091] The preparation method of super bright polyester filament for cross-stitching, the steps are as follows:

[0092] (1) prepare modified polyester;

[0093] (1.1) Preparation of 2-tert-butyl-1,6-hexanedicarboxylic acid;

[0094] First, mix tungstic acid and hydrogen peroxide, stir at room temperature for 10 minutes, then add 2-tert-butylcyclohexanol and react at 80°C for 1 hour, then raise the temperature to 94°C for 2 hours. During the reaction, the reactants are always It is in a reflux state, and finally undergoes cooling crystallization, washing and refining, wherein at the beginning of the reaction, the molar ratio of tungstic acid, 2-tert-butylcyclohexanol and hydrogen peroxide is 1:35:120;

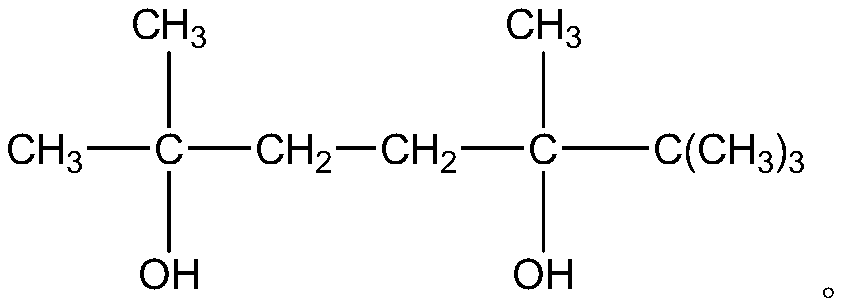

[0095] (1.2) Preparation of 2,2,5,5-tetramethyl-3,4-diethyl-3,4-hexanediol;

[0096] First, the molar ratio of 2,2-dimethyl 3-pentanone to sulfuric acid is 1.6:1, the concentration is 350g / L of 2,2-dimethyl 3-pentanone solution and the concentration is 210g / L The dilute sulf...

Embodiment 3

[0109] The preparation method of super bright polyester filament for cross-stitching, the steps are as follows:

[0110] (1) prepare modified polyester;

[0111] (1.1) Preparation of 2-tert-butyl-1,6-hexanedicarboxylic acid;

[0112] First, mix tungstic acid and hydrogen peroxide, stir at room temperature for 12 minutes, then add 2-tert-butylcyclohexanol and react at 83°C for 1.5h, then raise the temperature to 90°C for 2h. During the reaction, the reactants Always in a reflux state, and finally carry out cooling crystallization, washing and refining, wherein at the beginning of the reaction, the molar ratio of tungstic acid, 2-tert-butylcyclohexanol and hydrogen peroxide is 1:33:120;

[0113] (1.2) Preparation of 2,2,4,4-tetramethyl-3,4-di-tert-butyl-3,4-hexanediol;

[0114] Firstly, the molar ratio of 2,24,4-tetramethyl-3-pentanone to sulfuric acid is 1.7:1, the concentration is 340g / L 2,24,4-tetramethyl-3-pentanone solution and concentration A dilute sulfuric acid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com