Novel composite board and preparation method thereof

A composite board and a new type of technology, applied in the field of building boards, can solve the problems of large forest resources, ecological environment damage, easy thermal expansion and contraction, and achieve the effects of saving forest resources, natural and beautiful appearance, and natural and convenient materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

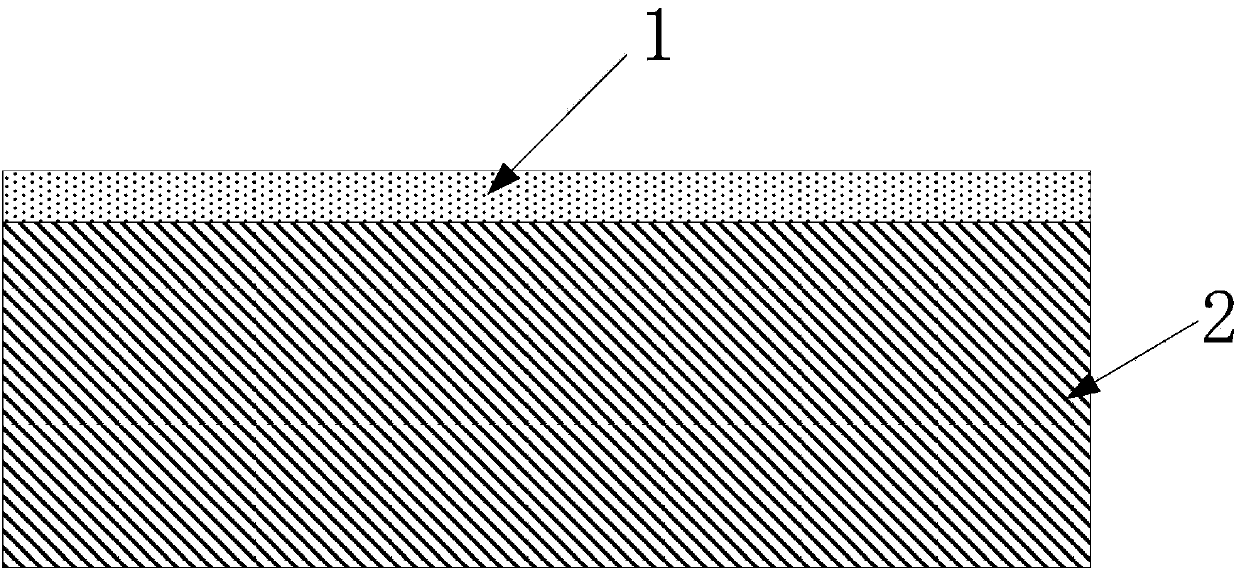

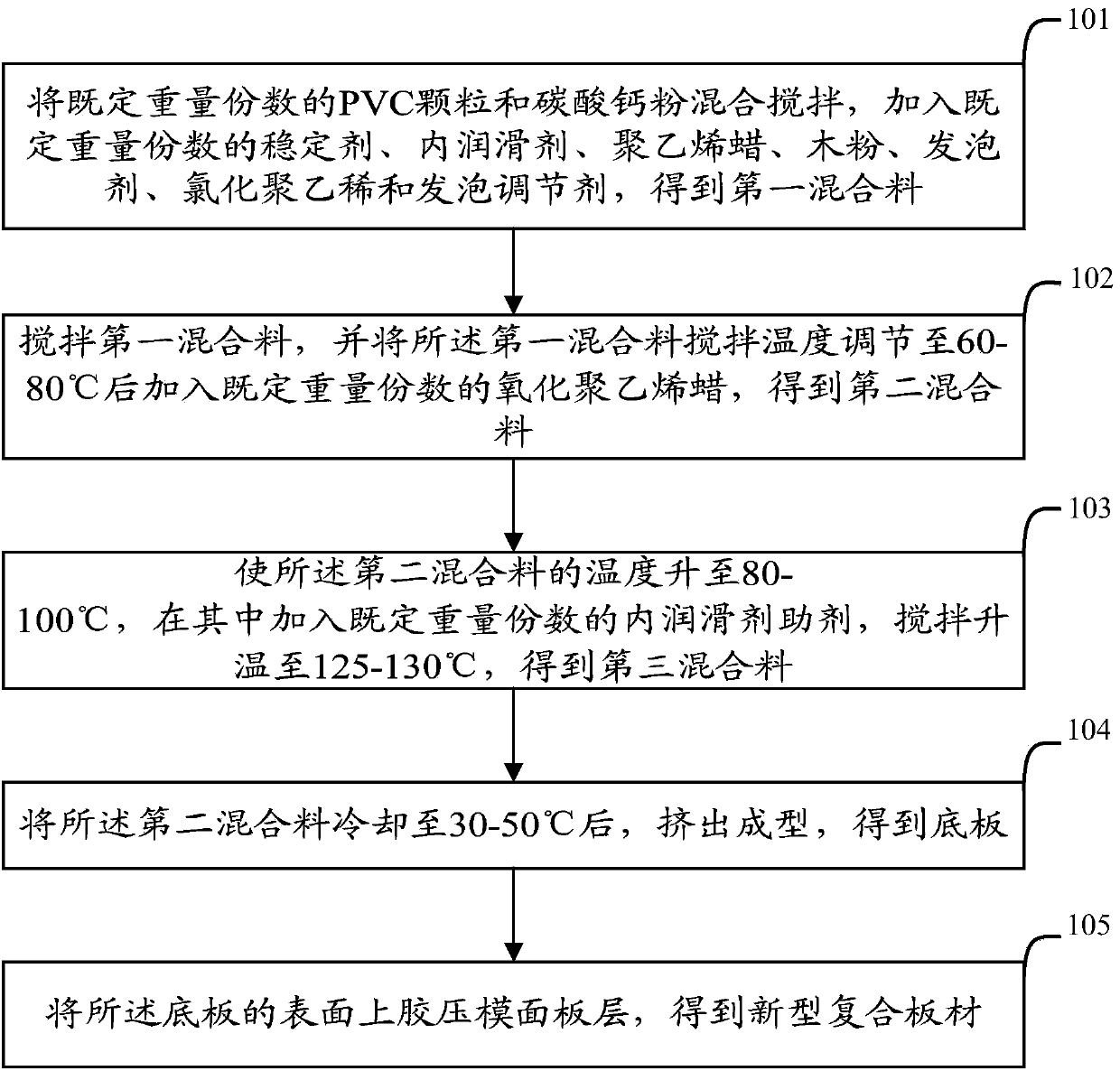

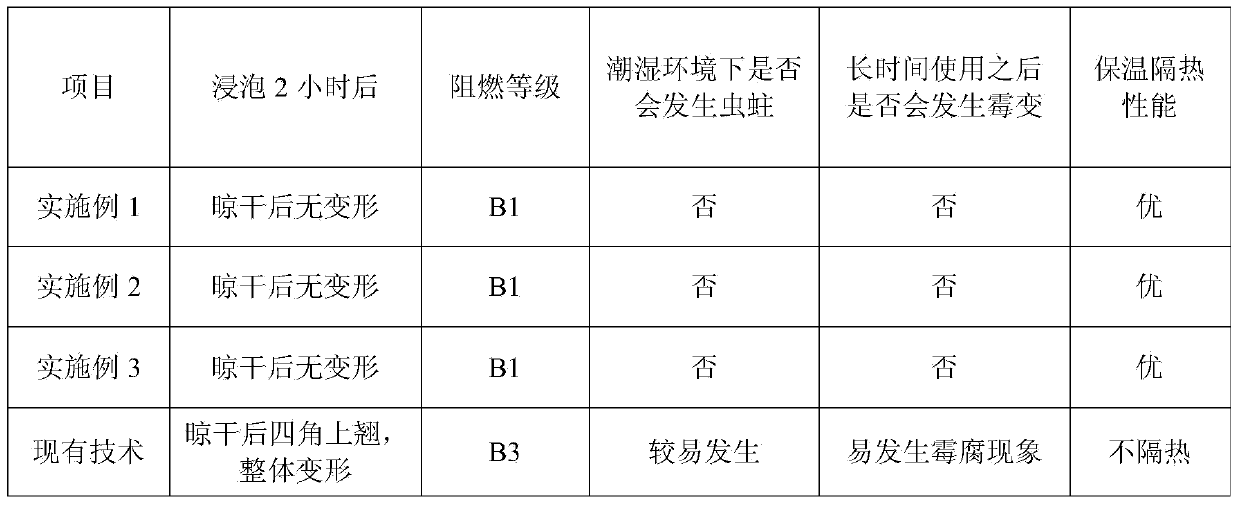

[0035] The new composite board of this embodiment includes: a bottom plate 2 and a panel layer 1; the panel layer 1 is pasted on the bottom plate 2;

[0036] In terms of parts by weight, the raw material components of the bottom plate 2 include: 90 parts of PVC particles, 40 parts of calcium carbonate powder, 3 parts of stabilizers, 1.0 part of foaming agent, 6 parts of foaming regulator, and 0.3 part of polyethylene wax. , 0.3 parts of internal lubricant, 0.2 parts of oxidized polyethylene wax, 4 parts of chlorinated polyethylene, 0.5 parts of internal lubricant additives, 9 parts of wood flour.

[0037] Among them, the panel layer 1 is a log or bamboo skin surface layer, and its thickness is 0.3mm. The foaming agent is composed of a mixture of AC yellow foaming agent and NC white foaming agent in a mass ratio of 1:3; panel layer 1 and bottom plate The thickness ratio of 2 is 1:8; the water content of the panel layer 1 is 6%.

Embodiment 2

[0039] The new composite board of this embodiment includes: a bottom plate 2 and a panel layer 1; the panel layer 1 is pasted on the bottom plate 2;

[0040] In terms of parts by weight, the raw material components of the bottom plate 2 include: 100 parts of PVC particles, 50 parts of calcium carbonate powder, 4.5 parts of stabilizers, 1.2 parts of foaming agents, 7 parts of foaming regulators, and 0.4 parts of polyethylene wax. , 0.35 parts of internal lubricant, 0.3 parts of oxidized polyethylene wax, 5 parts of chlorinated polyethylene, 1 part of internal lubricant additives, 10 parts of wood flour.

[0041] Among them, the panel layer 1 is a log or bamboo skin surface layer, and its thickness is 2mm. The foaming agent is composed of a mixture of AC yellow foaming agent and NC white foaming agent in a mass ratio of 1:3; panel layer 1 and bottom plate 2 The thickness ratio is 1:9; the water content of the panel layer 1 is 10%.

Embodiment 3

[0043] The new composite board of this embodiment includes: a bottom plate 2 and a panel layer 1; the panel layer 1 is pasted on the bottom plate 2;

[0044] In terms of parts by weight, the raw material components of the bottom plate 2 include: 110 parts of PVC particles, 60 parts of calcium carbonate powder, 6 parts of stabilizers, 1.4 parts of foaming agents, 8 parts of foaming regulators, and 0.5 parts of polyethylene wax. , 0.4 parts of internal lubricant, 0.4 parts of oxidized polyethylene wax, 6 parts of chlorinated polyethylene, 1.5 parts of internal lubricant additives, 11 parts of wood flour.

[0045] Among them, the panel layer 1 is a log or bamboo skin surface layer, and its thickness is 3mm. The foaming agent is composed of a mixture of AC yellow foaming agent and NC white foaming agent in a mass ratio of 1:3; panel layer 1 and bottom plate 2 The thickness ratio is 1:10; the water content of the panel layer 1 is 12%.

[0046] In addition, in all the embodiments of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com