Flame-retardant polyester fiber and preparation method thereof

A flame retardant polyester and fiber technology, applied in the field of polyester fibers, can solve the problems of high dyeing cost, high equipment requirements, poor dyeing performance, etc., and achieve the effects of reducing dyeing temperature, increasing oxygen adsorption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A preparation method of flame-retardant polyester fiber, the steps are as follows:

[0064] (1) prepare modified polyester;

[0065] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0066] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1:1:1.2:2.0, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

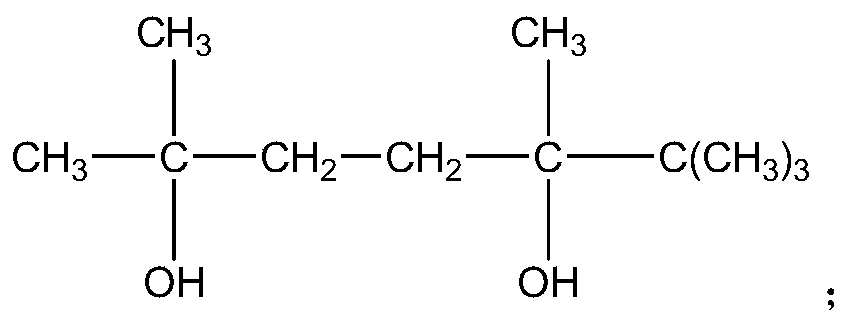

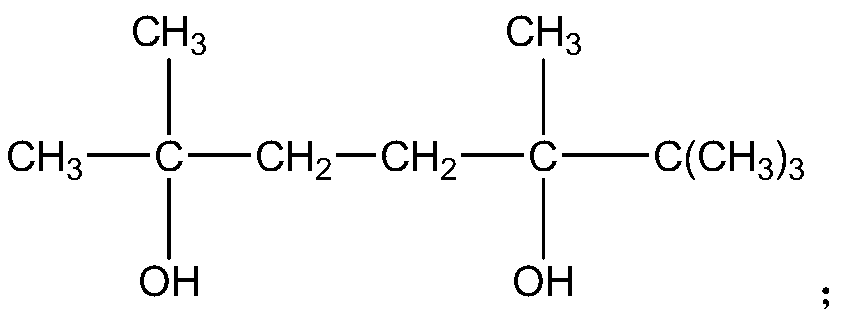

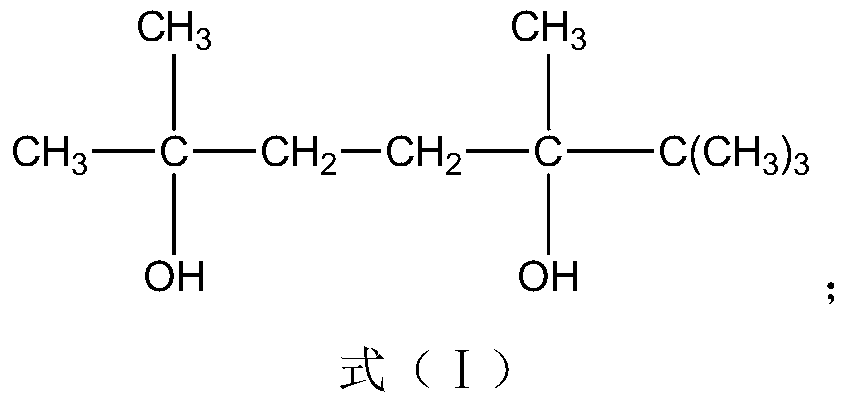

[0067] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 40°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0068] (1.2) Preparation of doped modified Bi 2 o 3 Powder;

[0069] (1.2.1) The concentration ...

Embodiment 2

[0088] A preparation method of flame-retardant polyester fiber, the steps are as follows:

[0089] (1) prepare modified polyester;

[0090] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0091] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.1:1:1.2:2.3, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

[0092] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 45°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0093] (1.2) Preparation of doped modified Bi 2 o 3 Powder;

[0094] (1.2.1) The concentratio...

Embodiment 3

[0107] A preparation method of flame-retardant polyester fiber, the steps are as follows:

[0108] (1) prepare modified polyester;

[0109] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0110] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.2:1:1.25:2.0, and place in an ice bath Under the conditions of reaction for 3 hours, after the reaction is completed, cooling and crystallization, centrifugation, washing, refining and drying are carried out to obtain octyne diol;

[0111] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 3:10:0.03, react at 40°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0112] (1.2) Preparation of doped modified Bi 2 o 3 Powder;

[0113] (1.2.1) Ca(NO 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com