Patents

Literature

41results about How to "Increase natural degradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complete extinction dacron low stretch yarns and preparation method thereof

ActiveCN109735927AIncreased free volumeImprove dye uptakeMonocomponent polyesters artificial filamentArtifical filament manufactureYarnFluorine containing

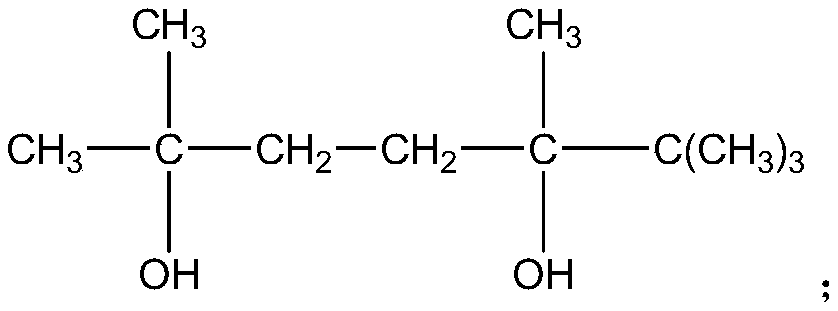

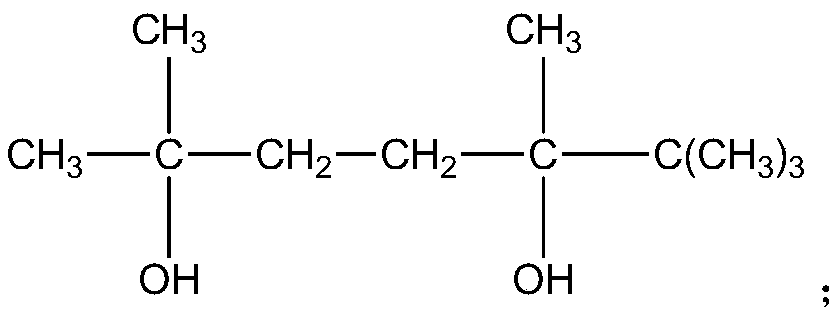

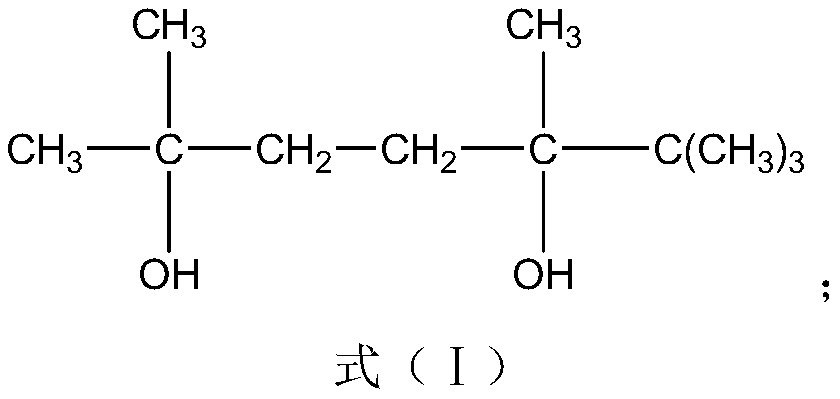

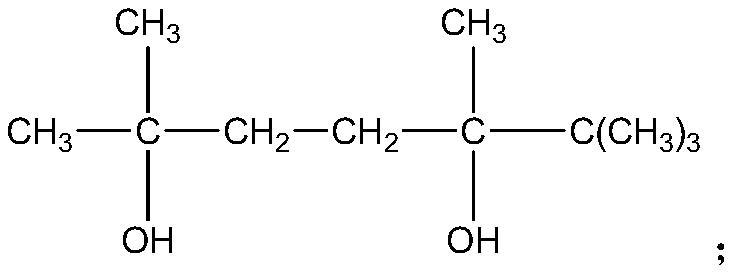

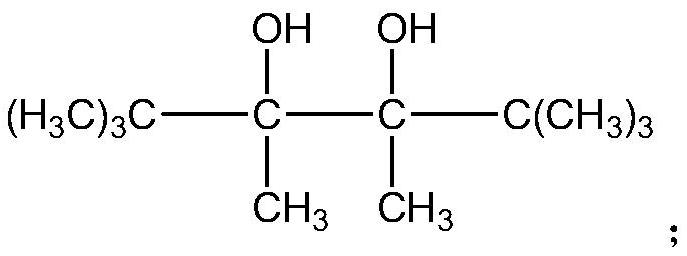

The invention relates to complete extinction dacron low stretch yarns and a preparation method thereof. The preparation method comprises the following steps: preparing modified polyester POY yarns from a modified polyester melt according to a POY process; and then preparing modified polyester DTY yarns from the modified polyester POY yarns according to a DTY process to obtain the complete extinction dacron low stretch yarns. A 2,5,6,6-tetramethyl-2,5-heptandiol chain segment, a fluorine-containing binary acid chain segment and a 2,2,3,4,5,5-hexamethyl-3,4-hexamethyl chain segment are introduced in molecular chains of the modified polyester, and an extinction agent, solid heteropolyacid powder roasted at a high temperature and doped and modified ZrO2 powder are dispersed in the modified polyester. The content of the extinction agent is greater than or equal to 2.0 wt%. The dye-uptake, the K / S value, the color fastness and the natural degrading efficiency of the prepared complete extinction dacron low stretch yarns are high. The method is simple in process, and the prepared complete extinction dacron low stretch yarns is good in dyeing performance and high in natural degrading efficiency.

Owner:JIANGSU HENGLI CHEM FIBER

Degradable polyester fiber and preparation method thereof

ActiveCN109722740AIncrease the free volume of spaceIncrease distanceMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentFiberGlutaric acid

The invention relates to a degradable polyester fiber and a preparation method thereof. The preparation method comprises the steps that modified polyester FDY filament is prepared from modified polyester melt according to an FDY process, and the degradable polyester fiber is obtained; the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment, a 2,5,6,6-tetramethyl-2,5-heptanediol chain segment and a fluorine-containing dicarboxylic acid chain segment; fluorine-containing dicarboxylic acid is 2,2-difluoro-1,3-malonic acid or 2,2-difluoro-1,4-succinic acid or 2,2-difluoro-1,5-glutaric acid or 2,2,3,3-tetrafluoro-1,4-succinic acid; modified ZrO2 doped powder is dispersed in modified polyester. After the obtained product is placed for 60 months on the conditions that the temperature is 25 DEG C, and the relative humidity is 65%, the intrinsic viscosity is lowered by 23-28%. The preparation method is low in cost and simple inprocess; the prepared product is high in natural degradation rate, and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester silk-imitation yarn and preparation method thereof

ActiveCN109750378AImprove dyeing effectImprove mechanical propertiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnColour fastness

The invention relates to polyester silk imitation yarn and a preparation method thereof. Pre-oriented yarn (POY) fiber and fully drawn yarn (FDY) fiber are doubled, wound and compounded to prepare thepolyester silk imitation yarn, the POY fiber and the FDY fiber are both triangle profile polyester fine denier fiber and take modified polyester as main raw materials, a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a binary acid chain segment with a tert-butyl pendant group, binary acid with the tert-butyl pendant group is 5-tert-butyl-1,3-phthalic acid, 2-tert-butyl-1,6-adipic acid, 3-tert-butyl-1,6-adipic acid, or 2,5-di-tert-butyl-1,6-adipic acid, multiphase solid acid and alkali powder SiO2-Al2O3 and / or SiO2-MgO subjected to high-temperature roasting is dispersed in the modified polyester, and the dye-uptake rate, the K / S value, the color fastness and the natural degradation efficiency of the polyester silk-imitation yarn are high. The preparation method is simple in technology, and the prepared polyester silk imitation yarn is excellent in dyeing performance and easy to degrade and recycle.

Owner:JIANGSU HENGLI CHEM FIBER

Cationic-dyeable polyester fiber and preparation method thereof

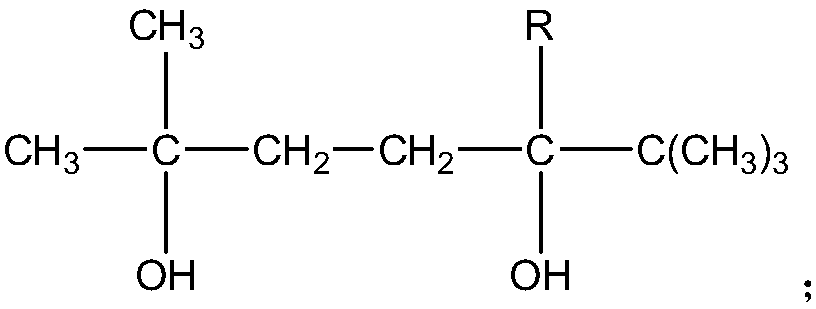

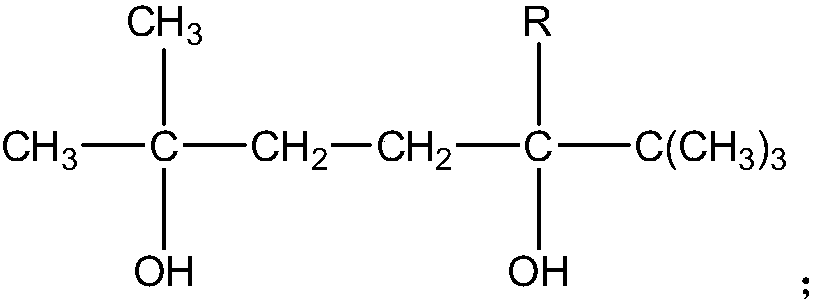

ActiveCN109680353AImprove permeabilityIncrease the void free volumeFilament/thread formingMonocomponent copolyesters artificial filamentFiberPolymer science

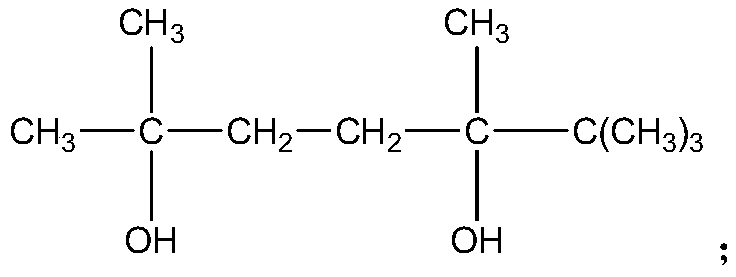

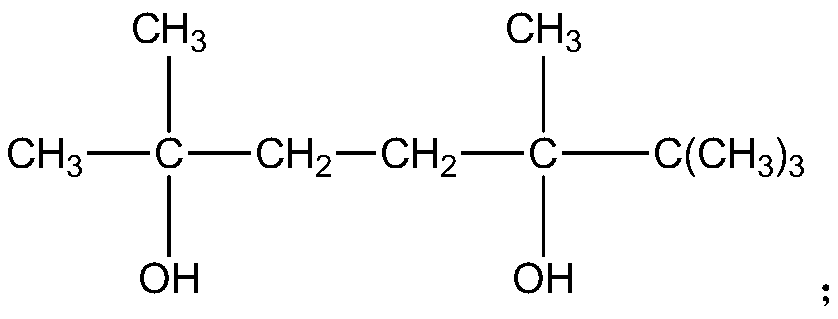

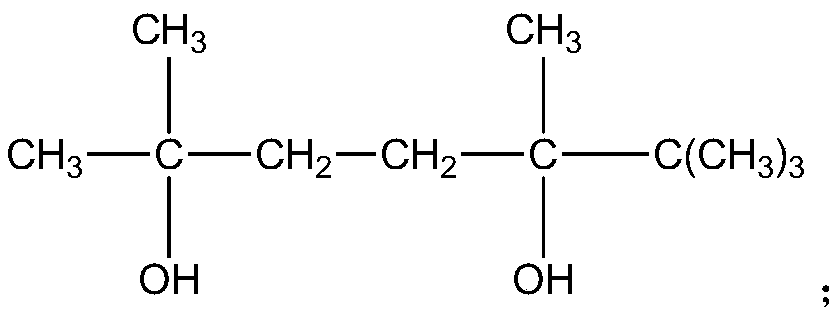

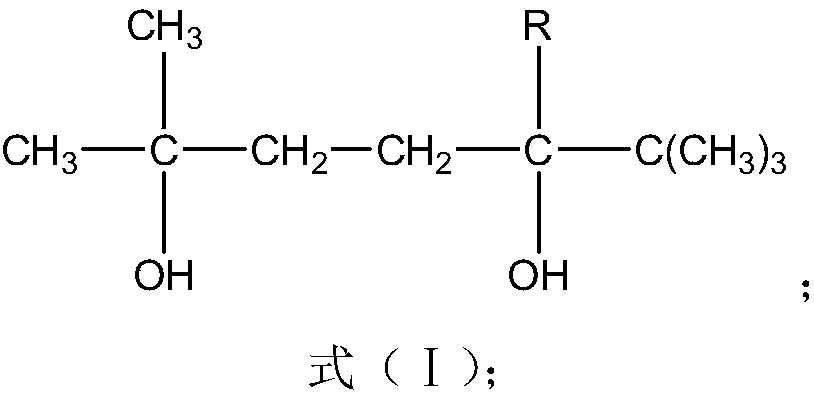

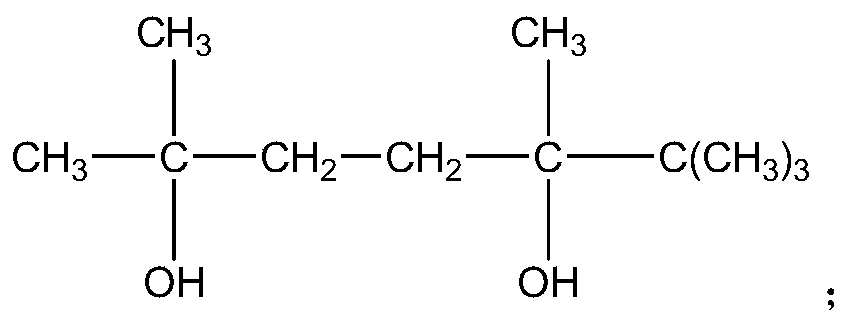

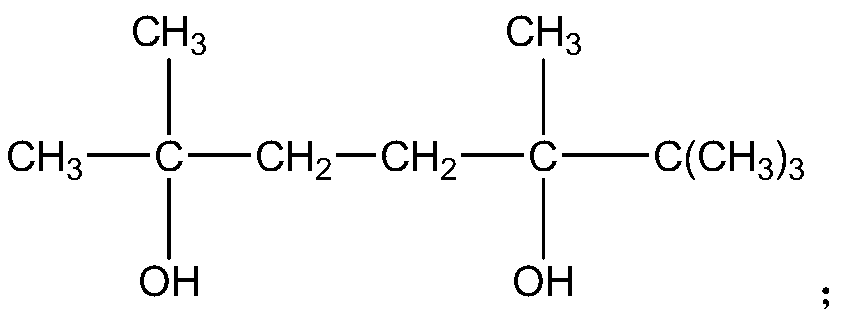

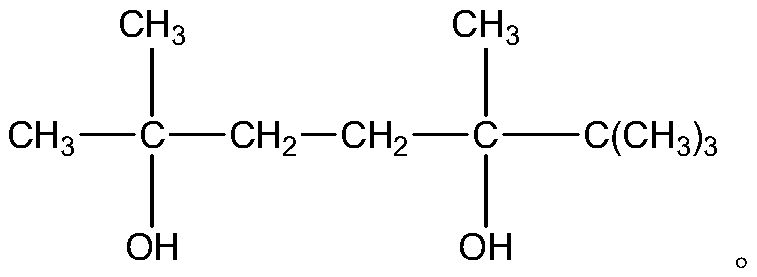

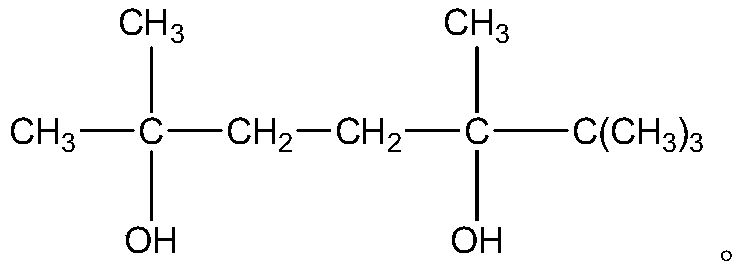

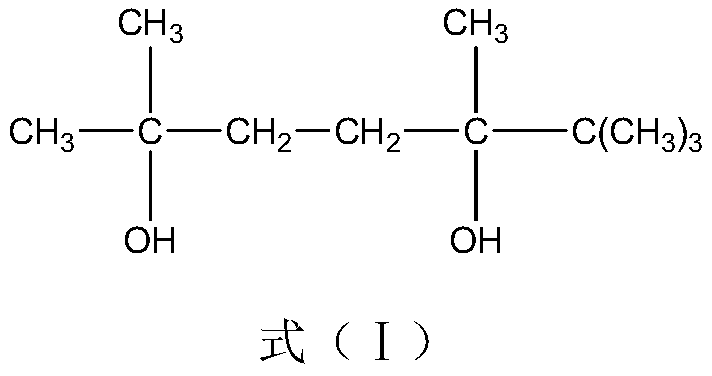

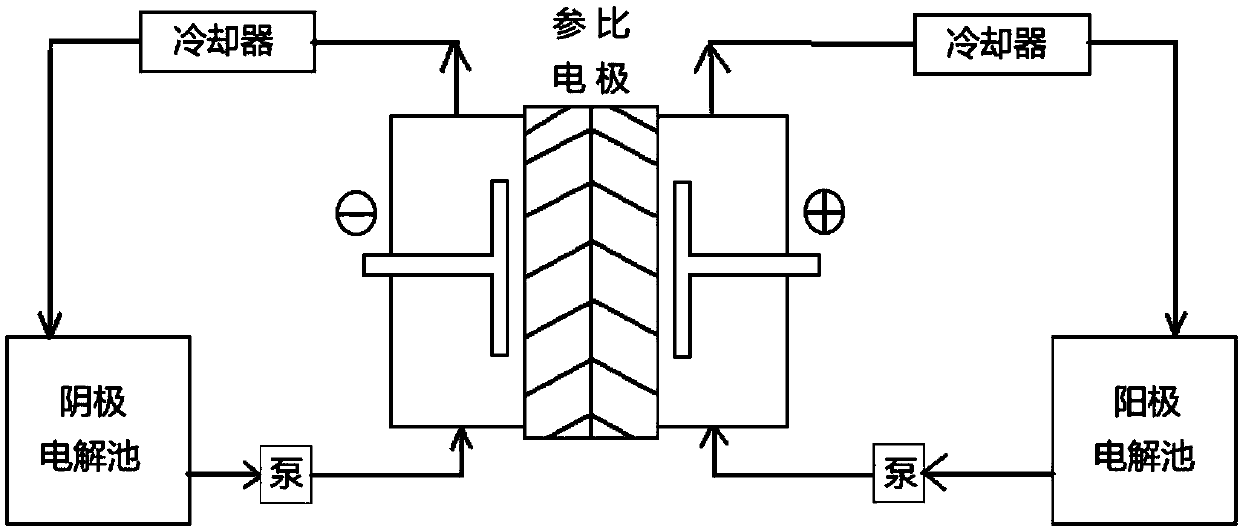

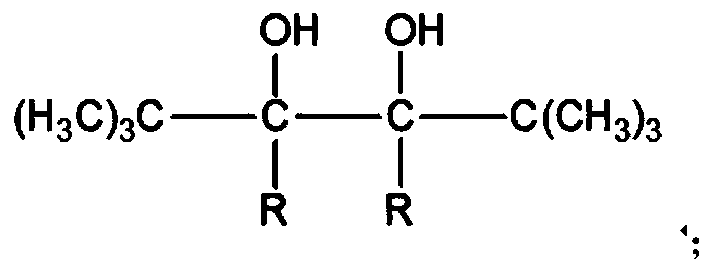

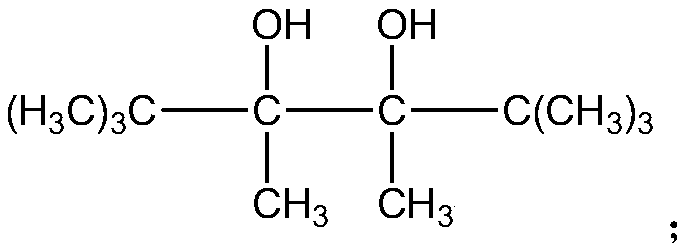

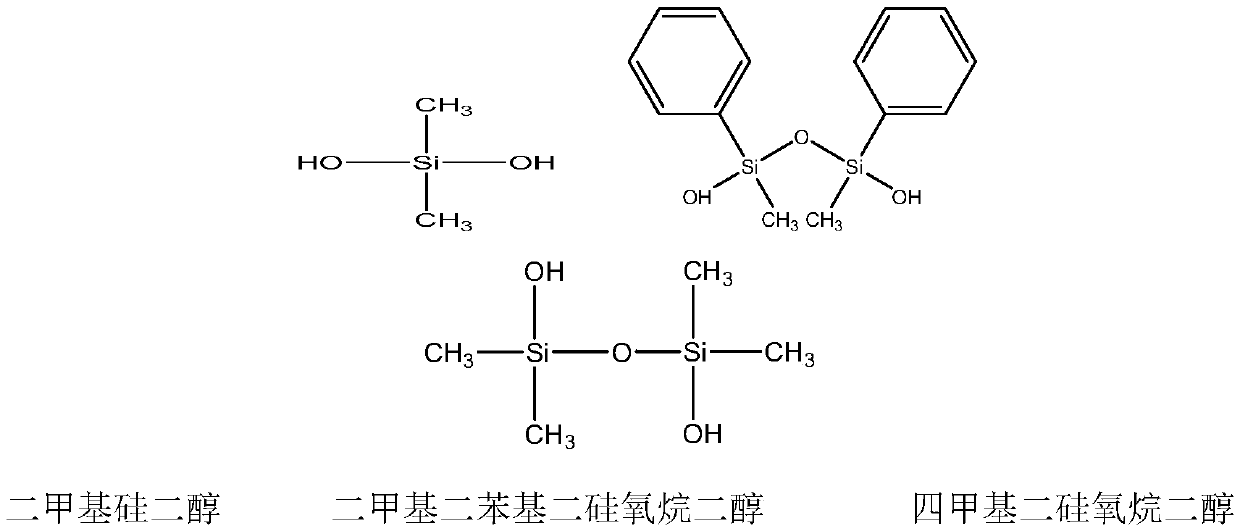

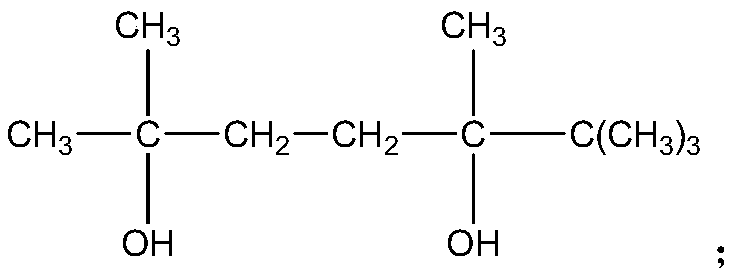

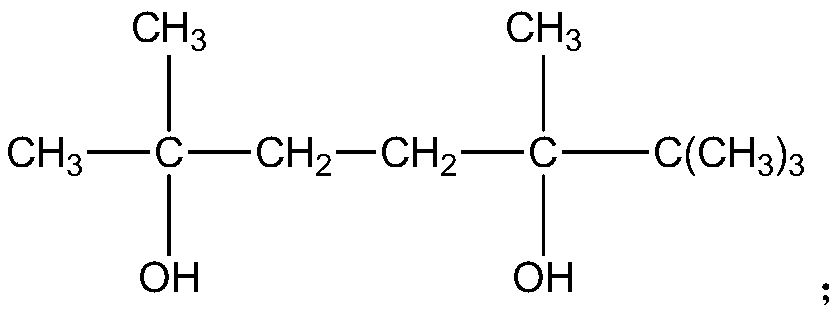

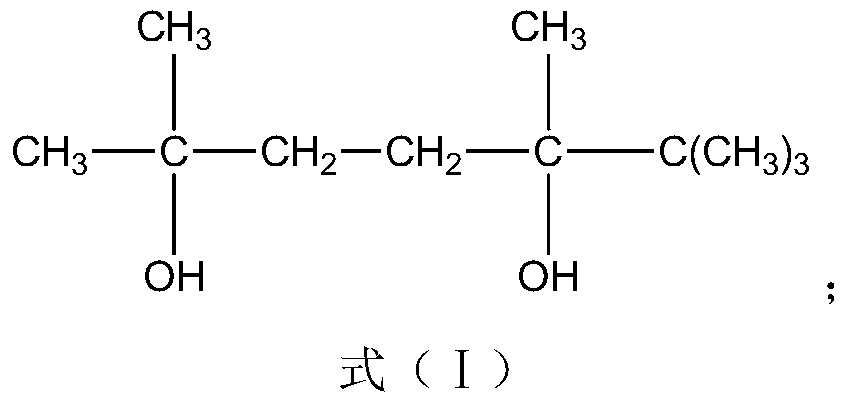

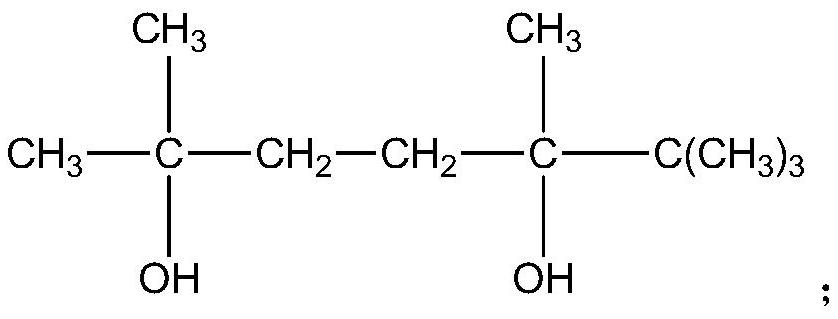

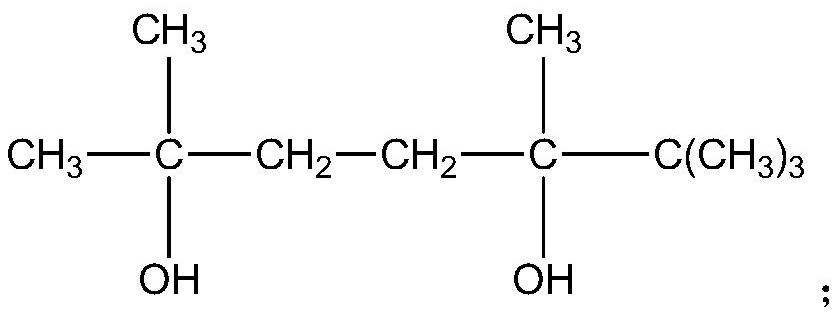

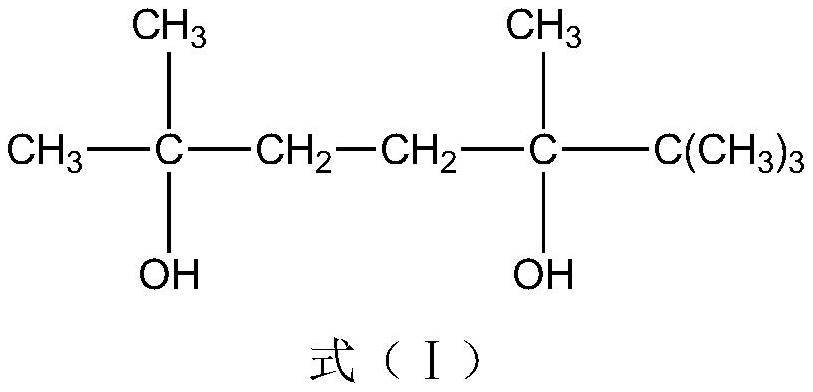

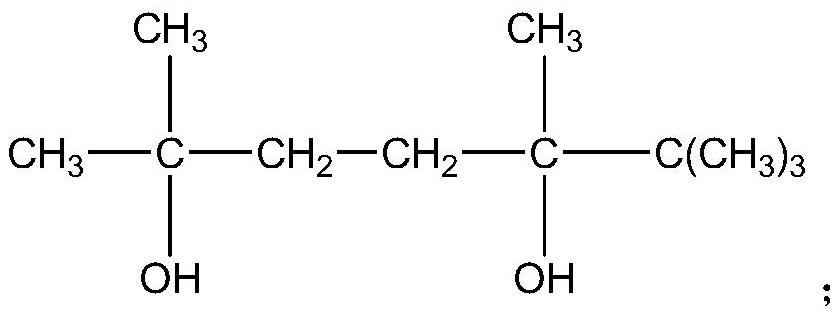

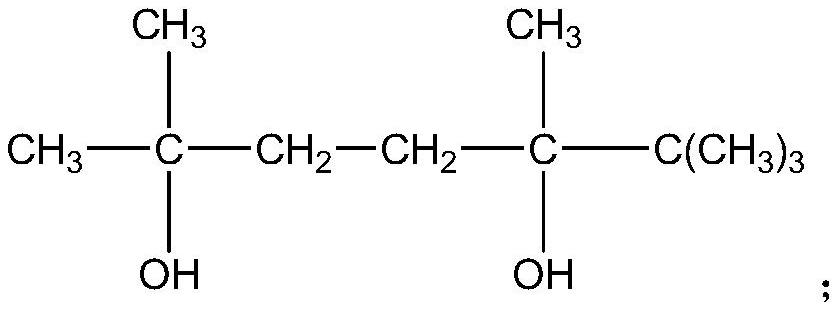

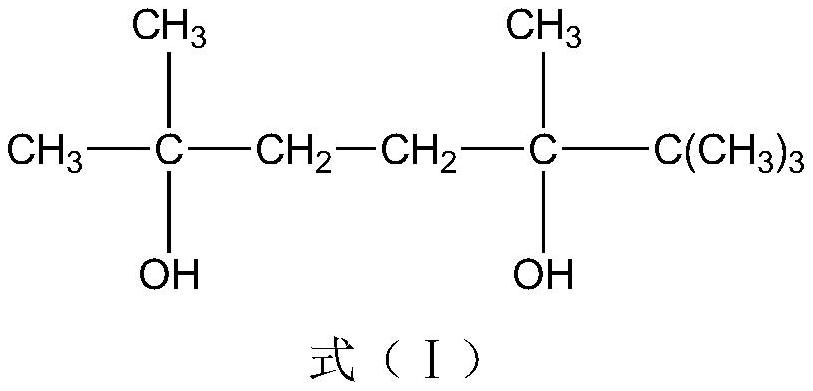

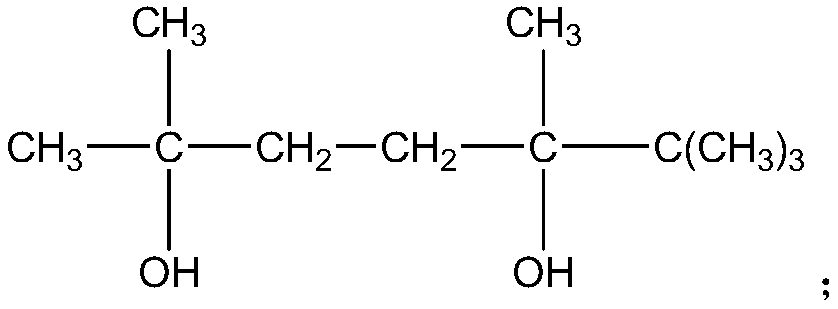

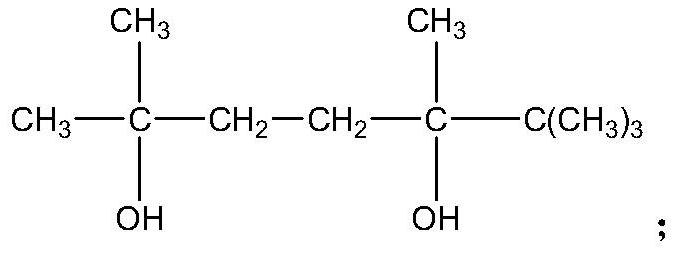

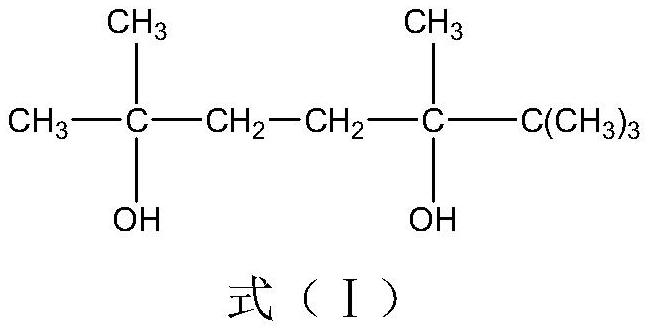

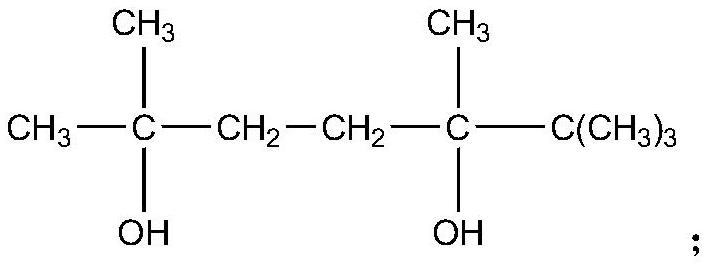

The invention relates to a cationic-dyeable polyester fiber and a preparation method thereof. The preparation method comprises the following steps: preparing cationic modified polyester FDY filamentsfrom cationic modified polyester melt according to an FDY process, thereby obtaining the cationic-dyeable polyester fiber. The molecular chains of the cationic modified polyester comprise terephthalicacid segments, ethylene glycol segments, sodium m-phthalate sulfonate segments and dihydric alcohol segments with tert-butyl side groups; the structural formula of the dihydric alcohol with tert-butyl side groups is as shown in the specification; and solid heteropoly acid powder subjected to high-temperature roasting is dispersed in the cationic modified polyester. The prepared product has dye-uptake of 87.8-92.2% under the temperature condition of 120 DEG C and the K / S value of 23.27-25.67; and after the product is placed under the conditions that the temperature is 25 DEG C and the relativehumidity is 65% for 60 months, the intrinsic viscosity is reduced by 13-17%. According to the preparation method disclosed by the invention, the addition amount of the third monomer is small, the cost is low, and the process is simple; and the prepared product is excellent in dyeing property and national degradation property.

Owner:JIANGSU HENGLI CHEM FIBER

Fiber for medical fabrics and preparation method of fiber

ActiveCN109706541AIncrease natural degradation rateSimple processMonocomponent polyesters artificial filamentArtifical filament manufactureFiberYarn

The invention relates to a fiber for medical fabrics and a preparation method of the fiber. The preparation method comprises the step that cationic polyester FDY yarn is prepared from cationic polyester according to the FDY technology to obtain the fiber for the medical fabrics, wherein nano-silver zeolite powder and SiO2-Al2O3 powder and / or SiO2-MgO powder which is / are sintered at the high temperature of 400-700 DEG C are dispersed in the cationic polyester, and molecular chain of the cationic polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a m-benzenedisulfonic acid disodium salt chain segment. After the prepared fiber for the medical fabrics is placed for 60 months under the condition that the temperature is 25 DEG C and the relative humidityis 65%, the characteristic viscosity of the fiber is reduced by 10-15%. The preparation method is simple in process and low in cost; the prepared product is high in natural degradation rate and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Moisture absorbing and sweat releasing polyester fibers and preparation method thereof

ActiveCN109505026AIncreased degradation rateFacilitate conductionMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to moisture absorbing and sweat releasing polyester fibers and a preparation method thereof. The preparation method comprises the following step: preparing polyester FDY yarns from a polyester melt according to a FDY process by using a cross-shaped spinneret plate to obtain the moisture absorbing and sweat releasing polyester fibers, wherein doped and modified ZrO powder is dispersed in the polyester melt. The doping and modifying process comprises the following steps: first, mixing a solution containing metal ions Mx<+> and a solution containing Zr4<+> uniformly; then dropwise adding a precipitator till the pH value of the solution is 9-10; and finally, calcining the precipitated product, wherein the metal ions Mx<+> are more than one of Mg2<+>, Li<+> and Zn2<+>. Thecross sections of the prepared moisture absorbing and sweat releasing polyester fibers are cross-shaped. The intrinsic viscosity of the moisture absorbing and sweat releasing polyester fibers is reduced by 10-16% if being placed for 60 months under the condition that the temperature of the moisture absorbing and sweat releasing polyester fibers is 25 DEG C and the relative humidity is 65%. The preparation method is simple in process and low in price. The prepared product is high in natural degrading speed, excellent in mechanical property and moisture absorbing and sweat releasing property, and has a good application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Feather-like polyester fiber and preparation method thereof

ActiveCN109750369AEnhanced interactionConvenient distanceFilament/thread formingMonocomponent copolyesters artificial filamentFiberPolymer science

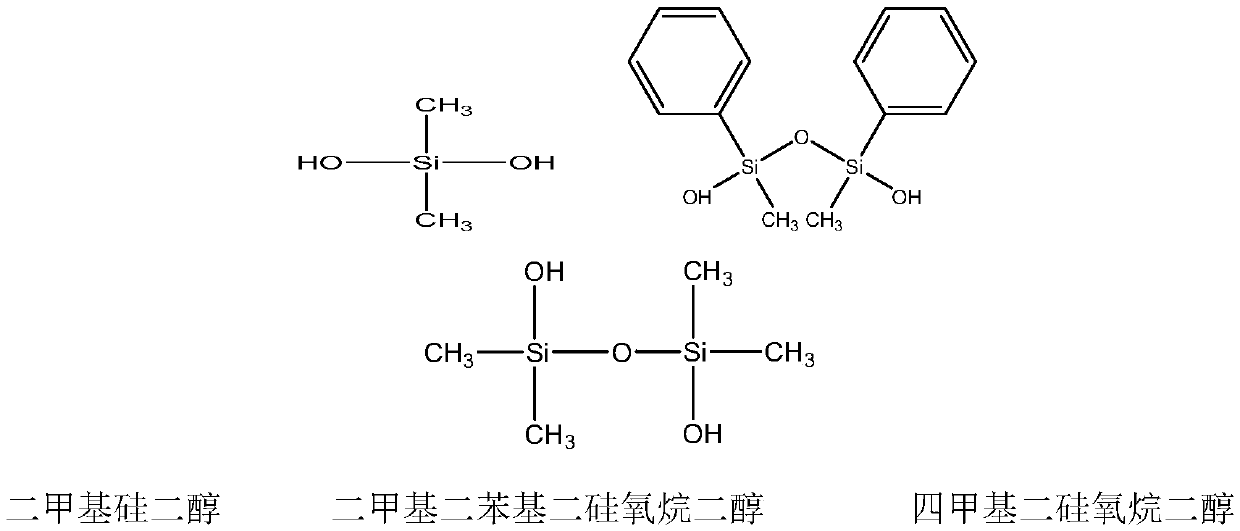

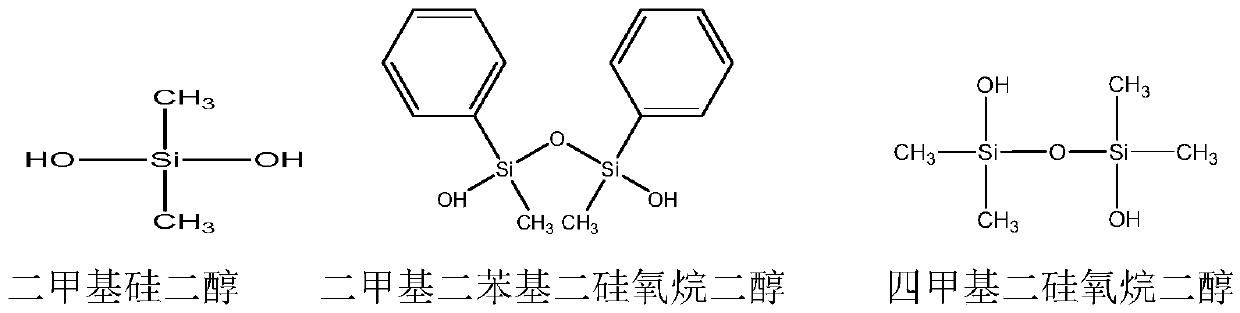

The invention relates to a feather-like polyester fiber and a preparation method thereof. The preparation method comprises the steps: firstly, terephthalic acid, ethylene glycol, dihydric alcohol witha main chain containing silicon, and fluorinated diacid are evenly mixed, and then an esterification reaction and a polycondensation reaction are carried out successively to prepare modified polyester; and then a modified polyester POY filament is prepared from modified polyester flux through a flat four-linking-ring-shaped spinneret plate according to a POY process, then a modified polyester DTYfilament is prepared from the modified polyester POY filament according to a DTY process, and then the feather-like polyester fiber is obtained. Spinneret orifices of the flat four-linking-ring-shaped spinneret plate are in a flat four-linking-ring shape. According to a prepared product, when the temperature is 130 DEG C, the dye-uptake is 89.6-93.7%; when the temperature is 25 DEG C and the relative humidity is 65%, after the product is placed for 60 months, the intrinsic viscosity of the product is lowered by 13-20%; and the preparation method is simple in process and low in cost, and the prepared product is excellent in dyeing property and high in natural degradation speed, and has good application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Flame-retardant polyester fiber and preparation method thereof

ActiveCN109706542AIncrease the free volume of spaceIncrease the void free volumeMonocomponent polyesters artificial filamentArtifical filament manufactureFiberYarn

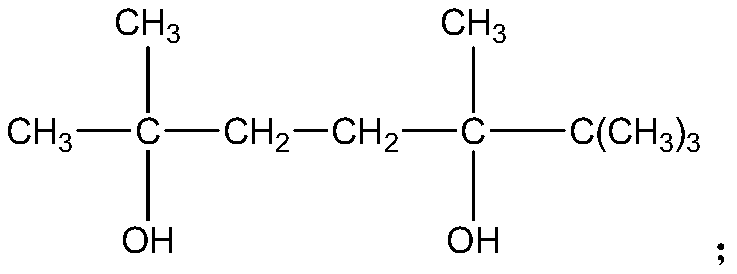

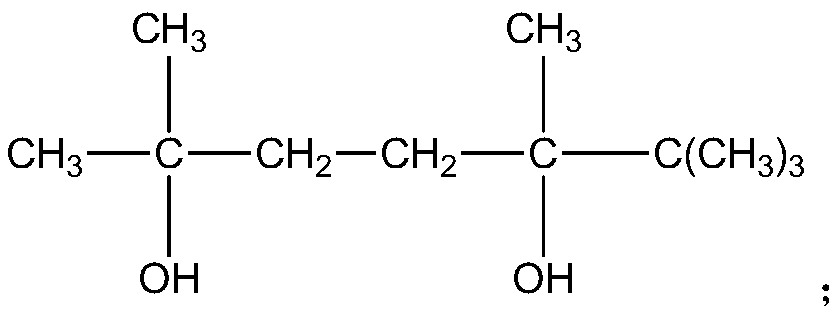

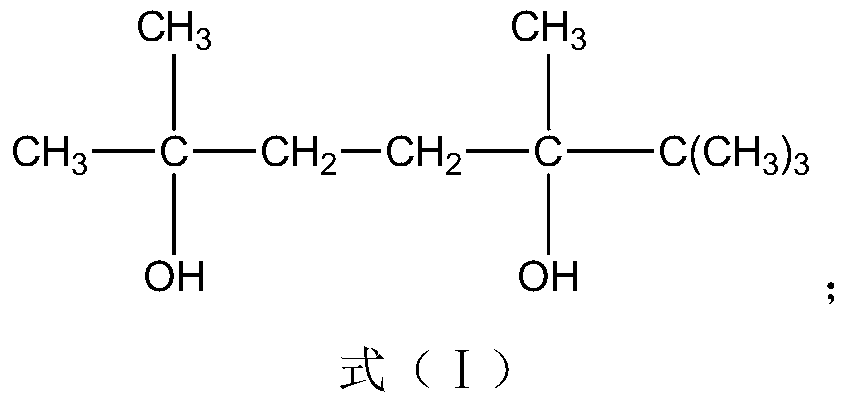

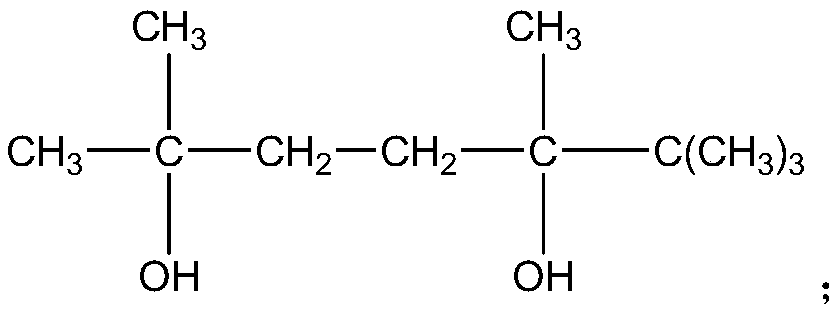

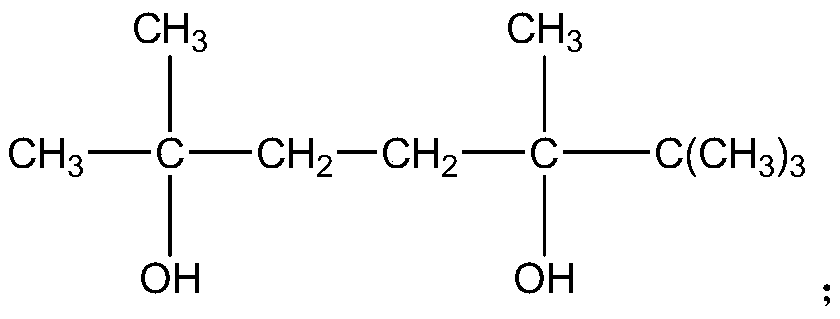

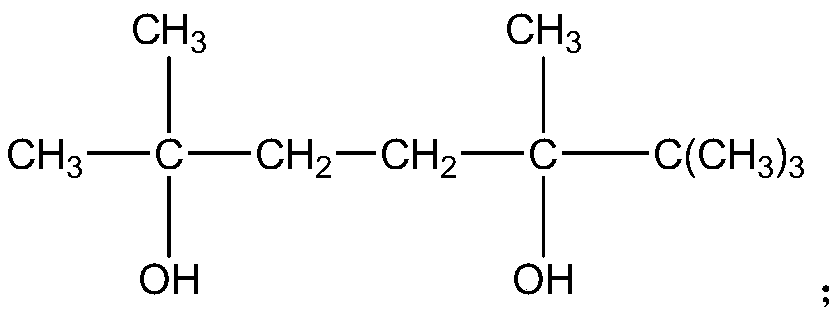

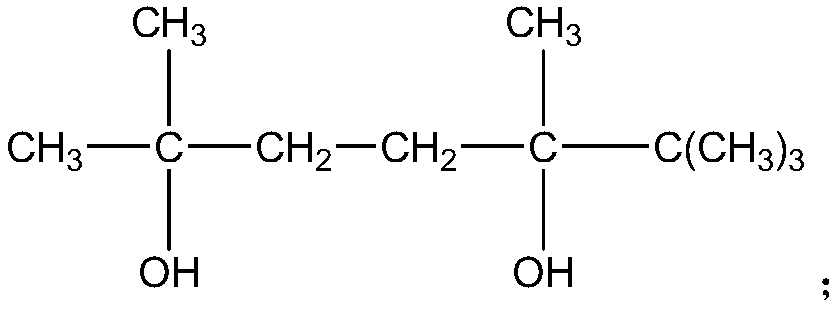

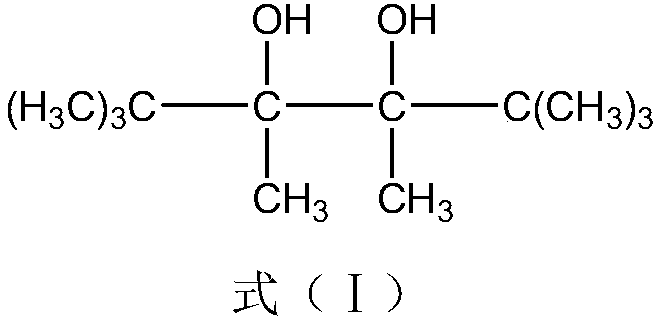

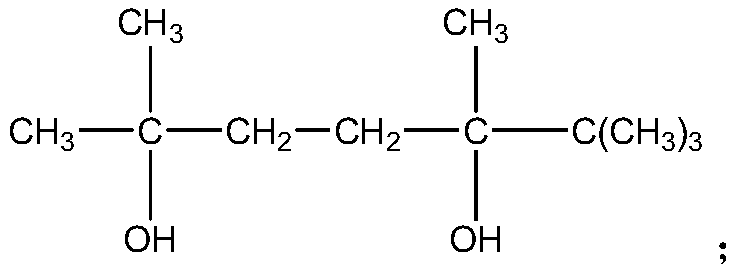

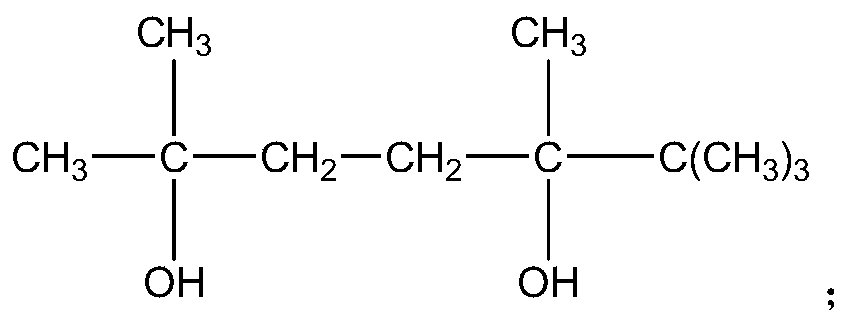

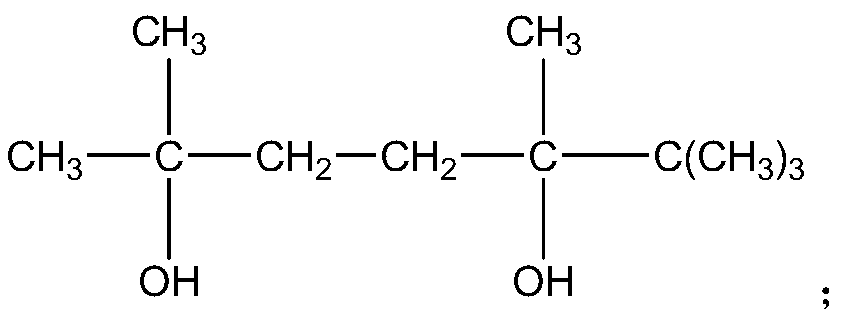

The invention relates to a flame-retardant polyester fiber and a preparation method thereof. The preparation method includes the step that modified polyester FDY yarn, namely the flame-retardant polyester fiber, is prepared from a modified polyester melt according to the FDY process. A preparation method of modified polyester comprises the step that terephthalic acid, ethylene glycol, 2-CEPPA, 2,5,6,6-tetramethyl-2,5-heptandiol and doped modified Bi2O3 powder are evenly mixed and subjected to an esterification reaction and a polycondensation reaction in sequence, wherein the structural formulaof 2,5,6,6-tetramethyl-2,5-heptandiol is shown in the description. The dye-uptake of the prepared product is 85.3-89.2% under the temperature condition of 120 DEG C, and the K / S value is 22.35-25.43;after the product is placed for 60 months under the condition that the temperature is 25 DEG C and the relative humidity is 65%, the characteristic viscosity of the product is reduced by 13-18%. Thepreparation method is low in cost and simple in process; the prepared product has excellent dyeing property and natural degradability.

Owner:JIANGSU HENGLI CHEM FIBER

Light heat-preservation fiber and preparation method thereof

ActiveCN109750375AImprove dye uptakeShorten the timeHollow filament manufactureFilament/thread formingYarnFiber

The invention relates to a light heat-preservation fiber and a preparation method thereof. The preparation method comprises the steps: a hollow spinneret plate is adopted, and modified polyester fullydrawn yarn (FDY), namely the light heat-preservation fiber is prepared from modified polyester melt according to a FDY process; and a molecular chain of modified polyester comprises a terephthalic acid chain segment, an ethanediol chain segment and a 2,5,6,6-tetramethyl-2,5-heptanediol chain segment, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is as followings (please see the specifications for the structural formula), and solid heteropoly acid powder roasted at the high temperature is dispersed in the modified polyester. According to the prepared product, when the temperature is 120 DEG C, the dye-uptake is 85.7-90.5%, and the K / S value is 22.54-25.87; and after the product is placed at the temperature of 25 DEG C and the relative humidity of 65% for 60 months, the intrinsic viscosity of the product is decreased by 13-17%. The preparation method is low cost and simple in process; and the prepared product is excellent in dyeing performance, and high in natural degradation rate, and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Semi-dull polyester drawn yarn and preparing method thereof

ActiveCN109722738AImprove dyeing effectPromote degradationMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to a semi-dull polyester drawn yarn and a preparing method thereof. The preparing method includes the step of repairing the semi-dull polyester drawn yarn from modified polyestermelt through an FDY process. A preparing method of modified polyester includes the steps of evenly mixing phthalic acid, ethylene glycol, dibasic alcohol with silicon in the main chain, fluorinated dibasic acid, a matting agent and doped and modified Bi2O3 powder, and sequentially conducting esterification reaction and condensation polymerization reaction, wherein the fluorinated dibasic acid is2,2-difluoro-1,3-malonic acid, 2,2-difluoro-1,4-succinic acid, 2,2-difluoro-1,5-glutaric acid or 2,2,3,3-tetrafluoro-1,4-succinic acid. The prepared product has the dye-uptake of 87.5-91.8% under thetemperature condition of 120 DEG C, and the specific viscosity of the product is reduced by 18-26% after the product is placed under the temperature of 25 DEG C and the relative humidity of 65% for 60months. The preparing method is simple in process, and the prepared product is good in dyeing and degrading performance.

Owner:JIANGSU HENGLI CHEM FIBER

Melt direct-spinning online added colored polyester fibers and preparation method thereof

ActiveCN109735939AIncrease the void free volumeIncrease natural degradation ratePigment addition to spinning solutionMonocomponent polyesters artificial filamentDibasic acidYarn

The invention relates to melt direct-spinning online added colored polyester fibers and a preparation method thereof. The preparation method comprises the following steps: combining a melt direct-spinning online adding process with a FDY process and preparing the melt direct-spinning online added colored polyester fibers from a modified polyester melt according to the combined process; and addingcolor masterbatch online into the modified polyester melt in the melt direct-spinning process, wherein the prepared melt direct-spinning online added colored polyester fibers are modified polyester FDY yarns, and molecular chains of the modified polyester comprise a terephthalic acid chain section, an ethylene glycol chain section, a binary acid chain section with a tertiary butyl side group, a fluorine-containing binary acid chain section and a 2,5,6,6-tetramethyl-2,5-heptandiol chain section. The preparation method is simple. By modifying the polyester by means of the fluorine-containing binary acid, the binary acid with the tertiary butyl side group and the 2,5,6,6-tetramethyl-2,5-heptandiol, the hydrolysis rate of the polyester is improved, the natural degrading performance of the polyester fibers is improved, and the prepared product is excellent in mechanical property.

Owner:JIANGSU HENGLI CHEM FIBER

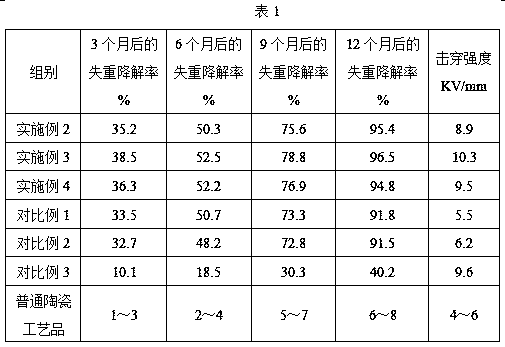

Environment-friendly ceramic artware and preparation method thereof

InactiveCN111099878AIncrease natural degradation rateGood adhesionCeramic materials productionCeramicwareMetallurgyNanostructured carbon

The invention discloses environment-friendly ceramic artware and a preparation method thereof. The environment-friendly ceramic artware comprises the following raw materials in parts by weight: 40-50parts of ceramic waste, 10-20 parts of fly ash, 10-15 parts of natural clay, 5-10 parts of sludge, 5-10 parts of natural straw, 2-8 parts of a binder, 5-10 parts of a pore-forming agent, 8-15 parts ofnano calcium carbonate and 5-10 parts of a fluxing agent. The environment-friendly ceramic artware disclosed by the invention is prepared from finely selected ceramic raw materials, the content of each raw material is optimized, the ceramic waste, the fly ash, the natural clay, the sludge, the natural straw, the binder, the pore-forming agent, the nano calcium carbonate and the fluxing agent areselected according to a proper ratio, the respective advantages are brought into full play, mutual complementation and mutual promotion are achieved, the natural degradation rate of the prepared environment-friendly ceramic artware is obviously increased, and the prepared environment-friendly ceramic artware is environmentally friendly, free of pollution and non-toxic and harmless to human bodiesand the environment. Moreover, the strength and the hardness of the ceramic artware can meet the use requirements.

Owner:QUANZHOU SUNSHINE CREATIVE CERAMICS CO LTD

Sheath-core flame retardant filament and preparation method thereof

ActiveCN109722741AEnhanced Offensive CapabilitiesIncreased degradation rateFlame-proof filament manufactureConjugated synthetic polymer artificial filamentsSolid baseRelative humidity

The invention relates to a sheath-core flame retardant filament and a preparation method thereof. The preparation method comprises the steps that the sheath-core flame retardant filament is prepared from chinlon and polyester according to an FDY process by means of a sheath-core composite spinning method; both chinlon and polyester contain fire retardant and solid base catalyst powder subjected tohigh-temperature calcining, the high-temperature calcining temperature is 400-700 DEG C, and the solid base catalyst is one or more of MgO, BaO and SiO2-BaO. The limit oxygen index of the prepared product is 28-30; after the product is placed for 60 months on the condition that the temperature is 25 DEG C, and the relative humidity is 65%, the cortical characteristic viscosity is lowered by 13-18%, and the core layer viscosity is lowered by 10-16%. The preparation method is low in cost and simple in process; the prepared product is excellent in flame retardant property and high in natural degradation rate, and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Moisture-absorbing and sweat-releasing polyester fibre and preparation method thereof

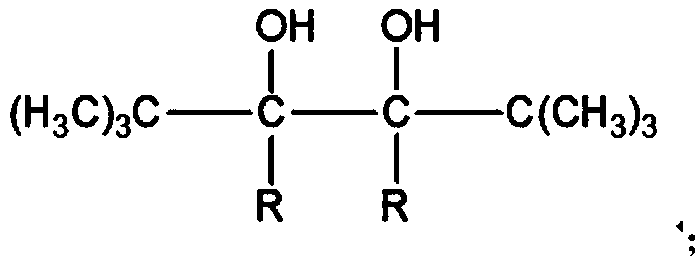

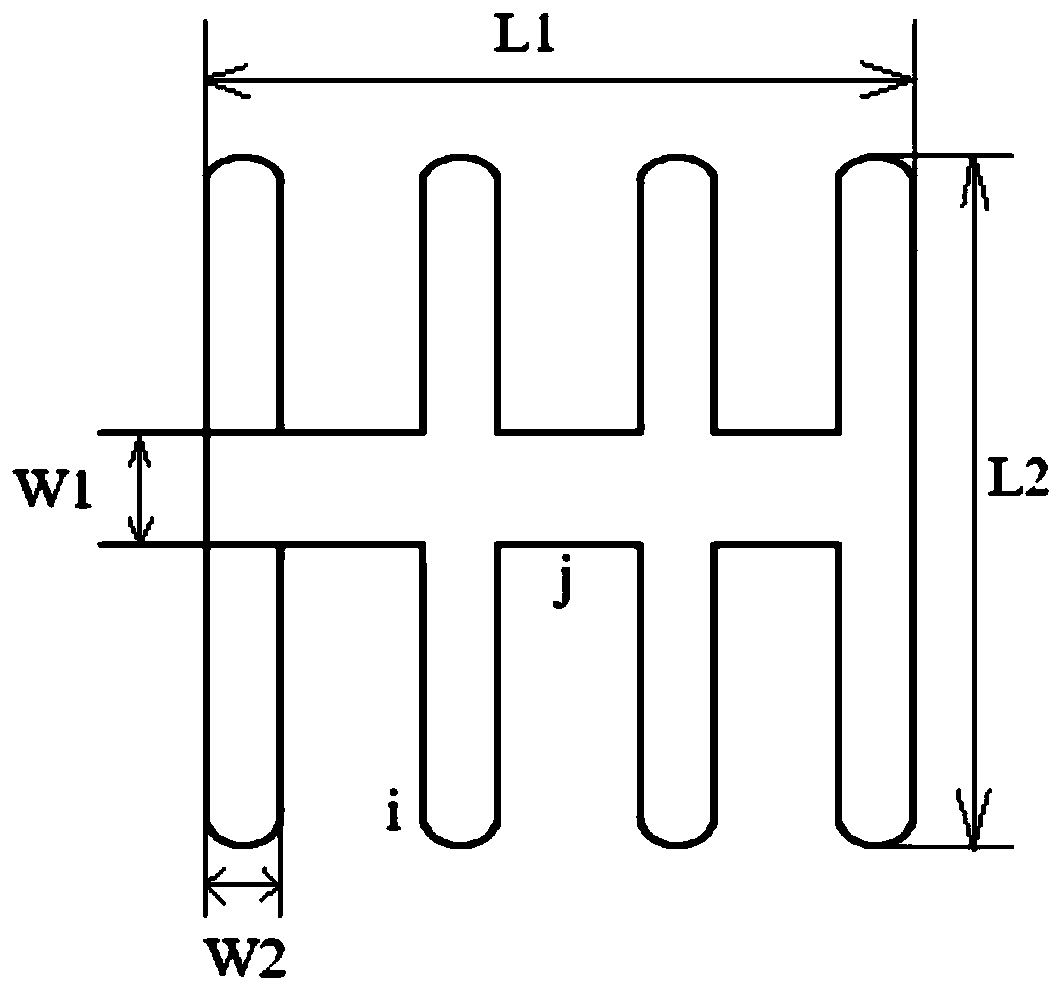

ActiveCN109666982AImprove dyeing performance (dye uptake)Increase speedMelt spinning methodsMonocomponent polyesters artificial filamentNatural degradationPolyester resin

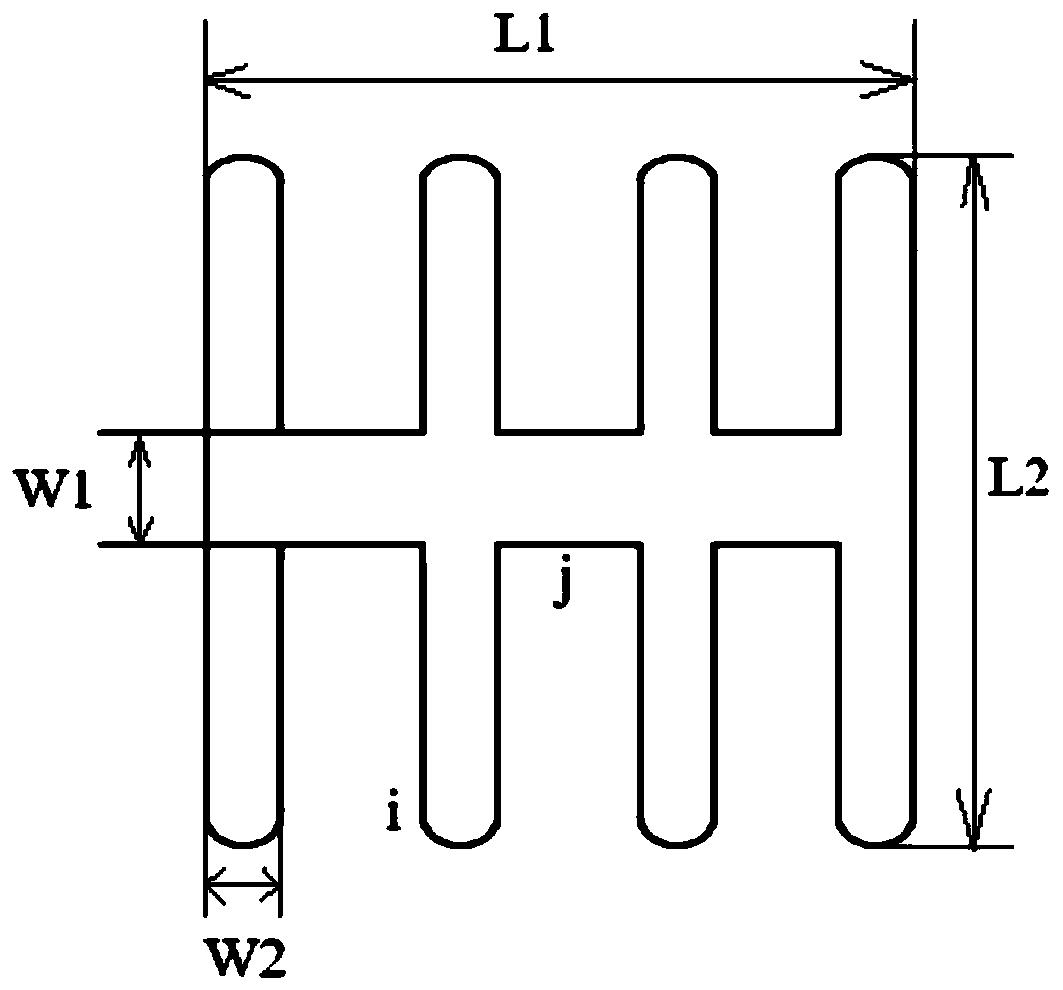

The invention relates to a moisture-absorbing and sweat-releasing polyester fibre and a preparation method thereof. The preparation method comprises the following steps: adopting an H-shaped spinneretplate to prepare modified polyester FDY filaments from modified polyester melt according to an FDY process, thereby obtaining the moisture-absorbing and sweat-releasing polyester fibre. The preparation method for modified polyester comprises the following steps: sequentially performing esterification reaction and polycondensation reaction after terephthalic acid, glycol, hexylene glycol with a tertiary butyl side group and doped modified ZrO2 powder are uniformly mixed. A structural formula of the hexylene glycol with the tertiary butyl side group is as follows: the formula is shown in the description. The prepared product has a dyeing rate of 86.7-90.2% under a temperature condition of 120 DEG C, and has a K / S value of 22.58-25.72; after being placed for 60 months under conditions with atemperature of 25 DEG C and relative humidity of 65%, intrinsic viscosity of the moisture-absorbing and sweat-releasing polyester fibre is reduced by 14-21%. The preparation method disclosed by the invention is low in cost and is simple in process; and the prepared product is excellent in dyeing performance, is quick in natural degradation rate, and has a promising application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Modified polyester fibers containing solid base catalyst and preparation method thereof

ActiveCN109722737ANo corrosionHigh selectivityMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to modified polyester fibers containing a solid base catalyst and a preparation method thereof. The preparation method includes the steps that according to a POY technology, after modified polyester melts are prepared into modified polyester POY filaments, and then according to a DTY technology, the modified polyester POY filaments are processed and prepared into the modifiedpolyester fibers containing the solid base catalyst; a modified polyester molecular chain comprises a terephthalic acid chain segment, an ethylene glycol chain segment and 2,5,6,6-tetramethyl-2,5-heptanediol chain segment, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in the specification, and solid base catalyst powder which is roasted at high temperature and doped and modified Sb2O3 powder are dispersed in modified polyesters. After the prepared product is put for 60 months under the conditions that the temperature is 25 DEG C and relative humidity is 65%, the intrinsic viscosity is decreased by 18-24%. The preparation method is low in cost and simple in technology; the prepared product is high in natural degrading rate and has broad application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Solid heteropoly acid-containing modified POY (Polyester) fibre and preparation method thereof

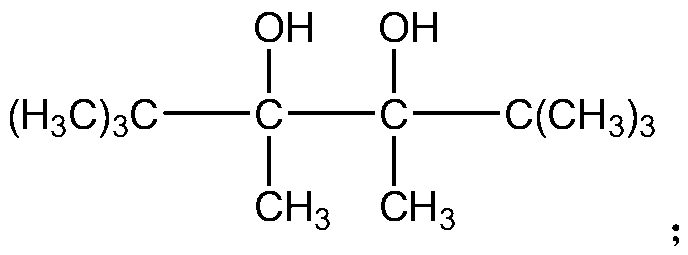

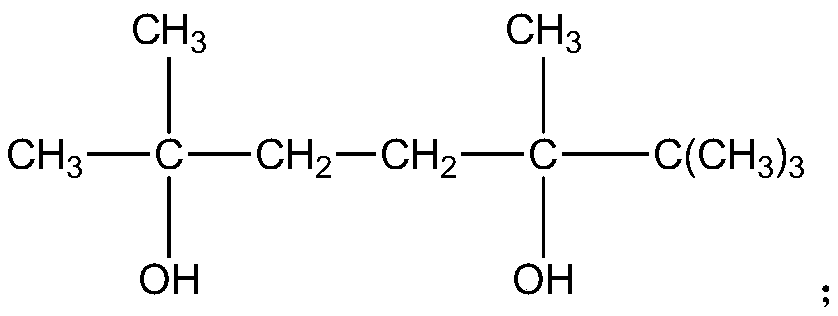

ActiveCN109666984AIncrease natural degradation rateHigh catalytic activityMonocomponent polyesters artificial filamentArtifical filament manufactureTO-18Polymer science

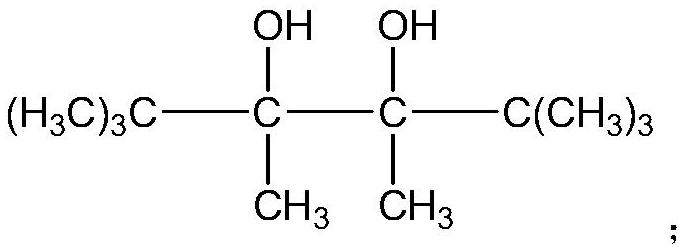

The invention relates to a solid heteropoly acid-containing modified POY (Polyester) fibre and a preparation method thereof. The preparation method comprises the following steps of: measuring modifiedpolyester melt, extruding the measured modified polyester melt through a spinneret plate, cooling, applying oil and winding to obtain the solid heteropoly acid-containing modified POY fibre; the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment, and a 2,2,3,4,5,5-hexamethyl-3,4-hexanediol chain segment; the structural formula of the 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as shown in the description; and solid heteropoly acid powder which is roasted at a high temperature and doped modified Sb2O3 powder are dispersed in themodified polyester. After the prepared product is placed for 60 months at the temperature of 25 DEG C and the relative humidity of 65 percent, the intrinsic viscosity is reduced by 12 to 18 percent.The preparation method provided by the invention is low in cost and simple in process; and the prepared product is high in natural degradation rate, and has a great application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Moisture absorption and perspiration polyester fiber and preparation method thereof

ActiveCN109505026BIncrease natural degradation rateSimple processMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to moisture absorbing and sweat releasing polyester fibers and a preparation method thereof. The preparation method comprises the following step: preparing polyester FDY yarns from a polyester melt according to a FDY process by using a cross-shaped spinneret plate to obtain the moisture absorbing and sweat releasing polyester fibers, wherein doped and modified ZrO powder is dispersed in the polyester melt. The doping and modifying process comprises the following steps: first, mixing a solution containing metal ions Mx<+> and a solution containing Zr4<+> uniformly; then dropwise adding a precipitator till the pH value of the solution is 9-10; and finally, calcining the precipitated product, wherein the metal ions Mx<+> are more than one of Mg2<+>, Li<+> and Zn2<+>. Thecross sections of the prepared moisture absorbing and sweat releasing polyester fibers are cross-shaped. The intrinsic viscosity of the moisture absorbing and sweat releasing polyester fibers is reduced by 10-16% if being placed for 60 months under the condition that the temperature of the moisture absorbing and sweat releasing polyester fibers is 25 DEG C and the relative humidity is 65%. The preparation method is simple in process and low in price. The prepared product is high in natural degrading speed, excellent in mechanical property and moisture absorbing and sweat releasing property, and has a good application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Skin core thermofuse and preparation method thereof

ActiveCN109853082ANatural degradation rate is fastImprove mechanical propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsMechanical propertyTerephthalic acid

The invention relates to a skin core thermofuse and a preparation method thereof. The preparation method comprises the step that a skin core composite spinning method is adopted for manufacturing theskin core thermofuse by adopting low-melting-point polyester as a skin layer and adopting PET as a core layer according to the FDY technology. The preparation method of PET comprises the steps that terephthalic acid, ethylene glycol, multi-phase solid acid-base powder calcinated under the temperature of 400-700 DEG C and doped and modified ZrO2 are mixed to be uniform, an esterification reaction and a condensation polymerization are performed successively, and multi-phase solid acid-base is SiO2-Al2O3 and / or SiO2-MgO. The obtained skin core thermofuse is placed under the temperature of 25 DEGC and the relative humidity of 65% for 60 months, then, the characteristic viscosity of the skin layer is lowered by 12-16%, and the characteristic viscosity of the core layer is lowered by 12-16%. The method is simple in technology, and the obtained skin core thermofuse is high in natural degradation rate and good in mechanical performance and has the application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Imitation feather yarn polyester fiber and preparation method thereof

ActiveCN109750369BIncrease natural degradation rateImprove dye uptakeFilament/thread formingMonocomponent copolyesters artificial filamentYarnFiber

Owner:JIANGSU HENGLI CHEM FIBER

A kind of degradable polyester fiber and preparation method thereof

ActiveCN111118650BIncrease natural degradation rateSimple processPlastic recyclingFilament/thread formingPolyesterFiber

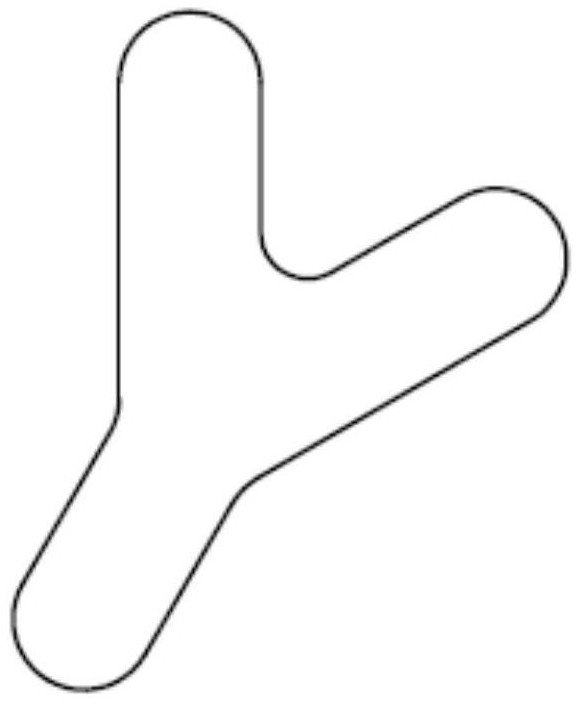

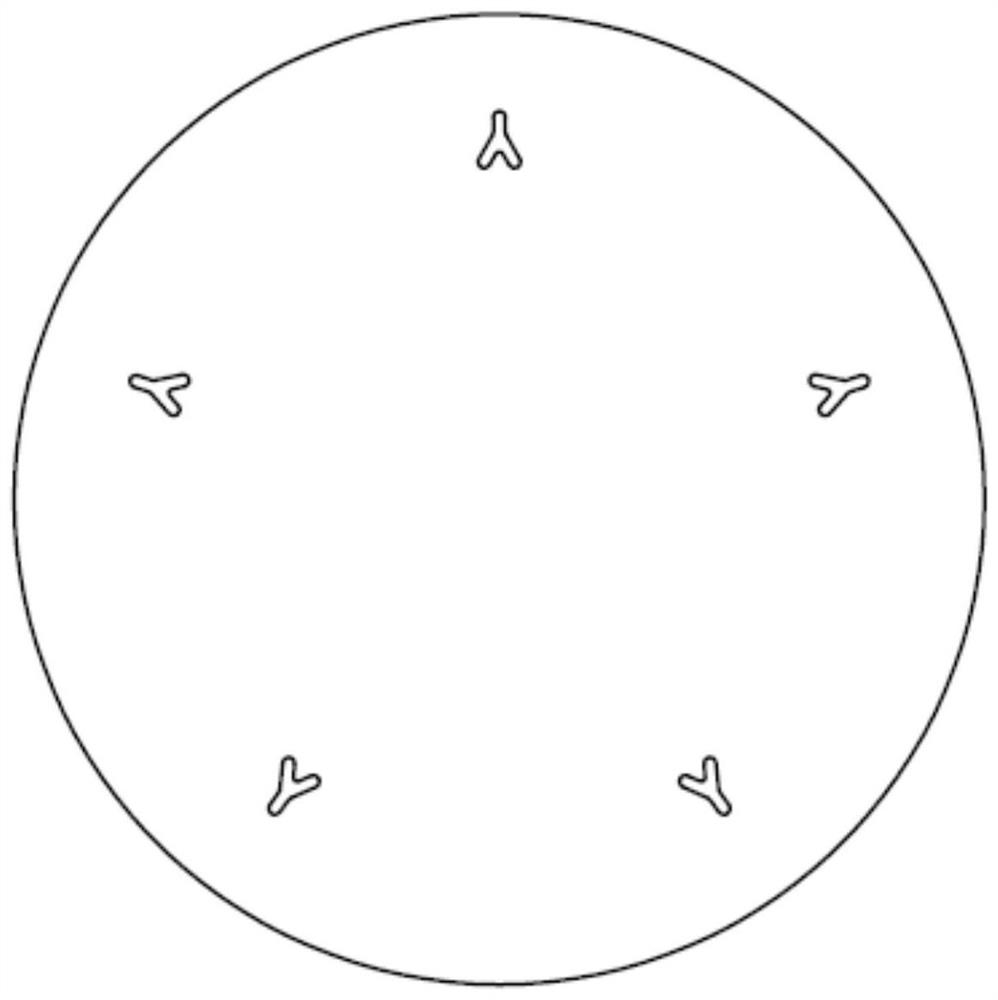

The invention relates to a degradable polyester fiber and a preparation method thereof. The preparation method is: dispersing doped and modified ZrO 2 The PET melt is extruded from the three-lobed spinneret hole on the spinneret and cooled by ring air, and FDY filaments are produced according to the FDY process, and then degradable polyester fibers are obtained through relaxation heat treatment; among them, the spinneret The three-lobed spinneret hole is a spinneret hole whose three lobes are not completely equal in length and the included angle between the three lobes is not exactly equal. All the three-lobed spinneret holes are distributed in concentric circles. The center line of the leaves opposite to the minimum angle passes through the center of the circle and points away from the center of the circle; the prepared degradable polyester fiber has a three-dimensional curled shape, and after being placed for 60 months at a temperature of 25°C and a relative humidity of 65%, Its intrinsic viscosity drops by 10-16%. The process of the invention is simple, and the prepared degradable polyester fiber has excellent degradability and good elasticity.

Owner:JIANGSU HENGLI CHEM FIBER

Complete extinction dacron pre-orientated yarns and preparation method thereof

ActiveCN109735934AImprove dyeing performance and natural degradation efficiencyHigh natural degradation efficiencyMonocomponent polyesters artificial filamentArtifical filament manufactureExtinctionIntrinsic viscosity

The invention relates to complete extinction dacron pre-orientated yarns and a preparation method thereof. The preparation method comprises the following step: preparing modified polyester POY yarns from a modified polyester melt according to a POY process to obtain the complete extinction dacron pre-orientated yarns; the preparation method of the modified polyester comprises the following steps:uniformly mixing terephthalic acid, ethylene glycol, 2,5,6,6-tetramethyl-2,5-heptandiol, fluorine-containing binary acid with a tertiary butyl side group, an extinction agent, dihydric alcohol with silicon on main chain, an extinction agent and multiphase solid acid-base powder roasted at a high temperature; and successively carrying out esterification reaction and polycondensation, wherein the multiphase solid acid-base is SiO2-Al2O3 and / or SiO2-MgO. The dye-uptake of a prepared product is 88.3-91.7% at a temperature of 125 DEG C, and the intrinsic viscosity of the product placed for 60 months at a temperature of 25 DEG C and relatively humidity of 65% is reduced by 16-20%. The preparation method is simple in process. The prepared product is good in dyeing performance and natural degrading performance.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of flame-retardant polyester fiber and preparation method thereof

ActiveCN109706542BImprove dye uptakeLower dyeing temperatureMonocomponent polyesters artificial filamentArtifical filament manufactureFiberYarn

The invention relates to a flame-retardant polyester fiber and a preparation method thereof. The preparation method includes the step that modified polyester FDY yarn, namely the flame-retardant polyester fiber, is prepared from a modified polyester melt according to the FDY process. A preparation method of modified polyester comprises the step that terephthalic acid, ethylene glycol, 2-CEPPA, 2,5,6,6-tetramethyl-2,5-heptandiol and doped modified Bi2O3 powder are evenly mixed and subjected to an esterification reaction and a polycondensation reaction in sequence, wherein the structural formulaof 2,5,6,6-tetramethyl-2,5-heptandiol is shown in the description. The dye-uptake of the prepared product is 85.3-89.2% under the temperature condition of 120 DEG C, and the K / S value is 22.35-25.43;after the product is placed for 60 months under the condition that the temperature is 25 DEG C and the relative humidity is 65%, the characteristic viscosity of the product is reduced by 13-18%. Thepreparation method is low in cost and simple in process; the prepared product has excellent dyeing property and natural degradability.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester nylon sheath-core composite yarn and preparation method thereof

ActiveCN109680362BNatural degradation rate is fastImprove mechanical propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolymer science

The invention relates to a polyester and nylon sheath core composite filament and a preparation method thereof. The method comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol, fluorine-containing binary acid and multi-phase solid acid-base powder which is roasted at a high temperature, and sequentially performing esterification and condensation polymerization to prepare modified polyester; preparing the polyester and nylon sheath core composite filament by using nylon and modified polyester as a sheath material and a core material by adopting a sheath-core compound spinning method according to the FDY process, wherein the high-temperature roasted multi-phase solid acid-base powder is dispersed in the nylon, and the multi-phase solid acid-base is SiO2-Al2O3 and / or SiO2-MgO; after the product is placed for 60 months at the temperature of 25 DEG C and the relative humidity of 65 percent, the sheath intrinsic viscosity is reduced by 13-18 percent, and the core intrinsic viscosity is reduced by 12-16 percent. The method has a simple process, and the polyester-nylon sheath-core composite filament has high natural degradation efficiency.

Owner:JIANGSU HENGLI CHEM FIBER

Anti-wear hydraulic oil and production process thereof

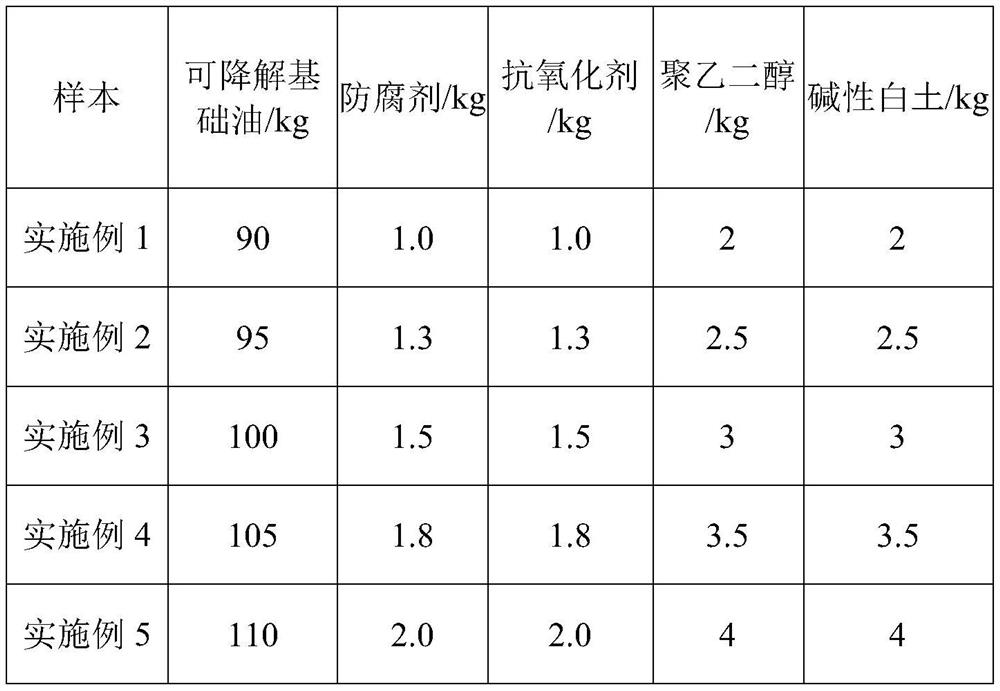

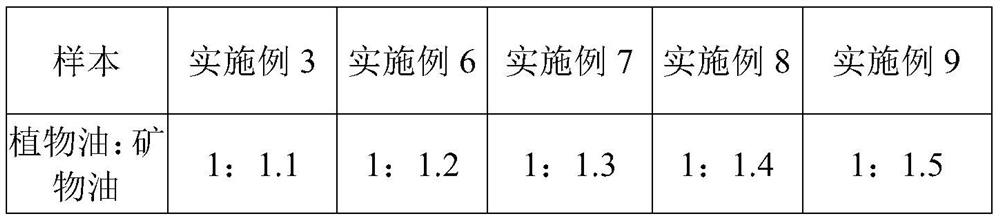

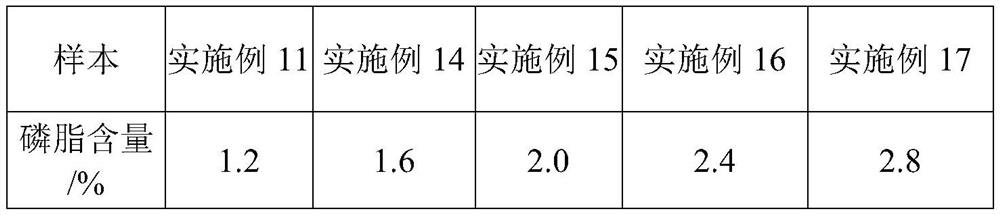

PendingCN113528223AExtended service lifeIncrease natural degradation rateLubricant compositionVegetable oilPreservative

The invention relates to the technical field of hydraulic oil, and particularly discloses anti-wear hydraulic oil and a production process thereof. The formula of the anti-wear hydraulic oil comprises the following raw materials in parts by weight: 90-110 parts of degradable base oil, 1-2 parts of a preservative, 1-2 parts of an antioxidant, 2-4 parts of polyethylene glycol and 2-4 parts of alkaline carclazyte, wherein the degradable base oil is prepared by compounding vegetable oil and mineral oil. The polyethylene glycol and the alkaline carclazyte have a synergistic effect, so that the possibility of degradation of the anti-wear hydraulic oil in the use process is reduced, and the service life of the anti-wear hydraulic oil is prolonged.

Owner:陕西喜盛石油化工有限公司

Degradable polyester fiber and its preparation method

ActiveCN109722740BIncrease natural degradation rateLow costMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a degradable polyester fiber and a preparation method thereof. The preparation method is as follows: a modified polyester FDY filament is prepared from a modified polyester melt according to an FDY process, and a degradable polyester fiber is obtained; the modified polyester The molecular chain of the ester includes a terephthalic acid segment, an ethylene glycol segment, a 2,5,6,6-tetramethyl-2,5-heptanediol segment and a fluorine-containing dibasic acid segment; The dibasic acid is 2,2-difluoro-1,3-malonic acid, 2,2-difluoro-1,4-succinic acid, 2,2-difluoro-1,5-glutaric acid or 2 ,2,3,3‑tetrafluoro‑1,4‑succinic acid; doped modified ZrO dispersed in modified polyester 2 Powder. After the prepared product is placed for 60 months under the condition of 25°C and 65% relative humidity, its intrinsic viscosity decreases by 23-28%. The preparation method of the invention has low cost and simple process; the obtained product has a fast natural degradation rate and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of lightweight thermal fiber and preparation method thereof

ActiveCN109750375BImprove dye uptakeShorten the timeHollow filament manufactureFilament/thread formingFiberYarn

The invention relates to a light heat-preservation fiber and a preparation method thereof. The preparation method comprises the steps: a hollow spinneret plate is adopted, and modified polyester fullydrawn yarn (FDY), namely the light heat-preservation fiber is prepared from modified polyester melt according to a FDY process; and a molecular chain of modified polyester comprises a terephthalic acid chain segment, an ethanediol chain segment and a 2,5,6,6-tetramethyl-2,5-heptanediol chain segment, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is as followings (please see the specifications for the structural formula), and solid heteropoly acid powder roasted at the high temperature is dispersed in the modified polyester. According to the prepared product, when the temperature is 120 DEG C, the dye-uptake is 85.7-90.5%, and the K / S value is 22.54-25.87; and after the product is placed at the temperature of 25 DEG C and the relative humidity of 65% for 60 months, the intrinsic viscosity of the product is decreased by 13-17%. The preparation method is low cost and simple in process; and the prepared product is excellent in dyeing performance, and high in natural degradation rate, and has great application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

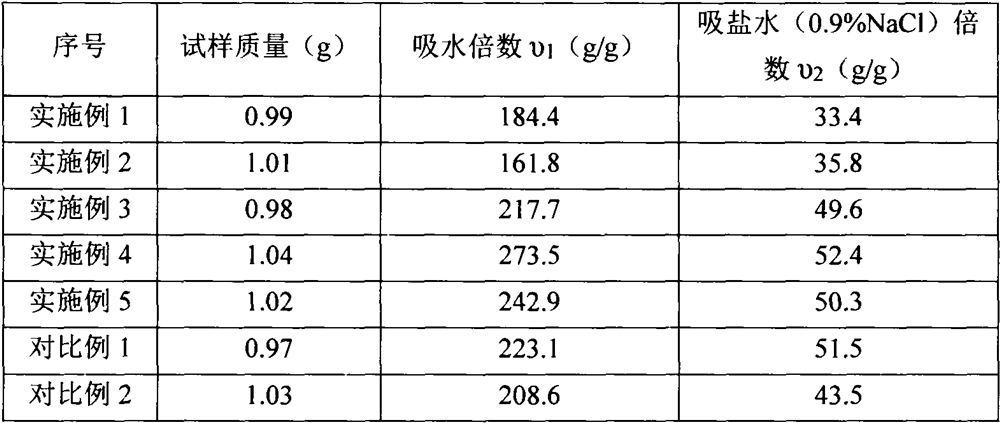

Preparation method of high-performance bio-based water and fertilizer slow-release material

InactiveCN112661573AImprove water absorption and retention capacityIncrease natural degradation rateFertilizer mixturesInorganic saltsOrganic acid

The invention provides a preparation method of a high-performance bio-based water and fertilizer slow-release material, which comprises the following steps: pulverizing a certain mass of plant straw into particles, adding the particles into a prepared strong alkali solution under stirring, and performing reacting at a certain temperature to obtain an alkaline liquid mixture; then adding a certain mass of inorganic porous material into the alkaline liquid mixture, performing stirring, finally mixing organic amide, humic acid, organic acid and a metal inorganic salt initiator according to a certain proportion, adding the mixture into the alkaline liquid mixture, and continuously performing reacting at a certain temperature; and taking out the reacted mixture, and performing drying to obtain the high-performance bio-based water and fertilizer slow-release material. On the basis of existing research, the preparation process of the bio-based high-water-absorptivity water-fertilizer slow-release material is optimized, the preparation method which is easy to operate, easy to control, low in cost and efficient in yield is obtained, and the preparation method is particularly suitable for meeting the requirement for application and popularization of the water-fertilizer slow-release material in agricultural production.

Owner:TIANJIN AGRICULTURE COLLEGE

A kind of modified polyester fiber containing solid alkali catalyst and preparation method thereof

ActiveCN109722737BIncrease natural degradation rateHigh catalytic activityMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to modified polyester fibers containing a solid base catalyst and a preparation method thereof. The preparation method includes the steps that according to a POY technology, after modified polyester melts are prepared into modified polyester POY filaments, and then according to a DTY technology, the modified polyester POY filaments are processed and prepared into the modifiedpolyester fibers containing the solid base catalyst; a modified polyester molecular chain comprises a terephthalic acid chain segment, an ethylene glycol chain segment and 2,5,6,6-tetramethyl-2,5-heptanediol chain segment, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in the specification, and solid base catalyst powder which is roasted at high temperature and doped and modified Sb2O3 powder are dispersed in modified polyesters. After the prepared product is put for 60 months under the conditions that the temperature is 25 DEG C and relative humidity is 65%, the intrinsic viscosity is decreased by 18-24%. The preparation method is low in cost and simple in technology; the prepared product is high in natural degrading rate and has broad application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

Full-dull polyester low elastic yarn and preparation method thereof

ActiveCN109735927BIncreased free volumeImprove dye uptakeMonocomponent polyesters artificial filamentArtifical filament manufactureYarnColour fastness

The invention relates to complete extinction dacron low stretch yarns and a preparation method thereof. The preparation method comprises the following steps: preparing modified polyester POY yarns from a modified polyester melt according to a POY process; and then preparing modified polyester DTY yarns from the modified polyester POY yarns according to a DTY process to obtain the complete extinction dacron low stretch yarns. A 2,5,6,6-tetramethyl-2,5-heptandiol chain segment, a fluorine-containing binary acid chain segment and a 2,2,3,4,5,5-hexamethyl-3,4-hexamethyl chain segment are introduced in molecular chains of the modified polyester, and an extinction agent, solid heteropolyacid powder roasted at a high temperature and doped and modified ZrO2 powder are dispersed in the modified polyester. The content of the extinction agent is greater than or equal to 2.0 wt%. The dye-uptake, the K / S value, the color fastness and the natural degrading efficiency of the prepared complete extinction dacron low stretch yarns are high. The method is simple in process, and the prepared complete extinction dacron low stretch yarns is good in dyeing performance and high in natural degrading efficiency.

Owner:JIANGSU HENGLI CHEM FIBER

Ultra-fine denier polyester low elastic yarn and preparation method thereof

ActiveCN109666989BIncrease natural degradation rateIncreased free volumeMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnFiber

The invention relates to ultrafine-denier polyester fiber low-stretch yarn and a preparation method thereof. The preparation method comprises the steps: preparing modified polyester POY (Pre-OrientedYarn) from modified polyester melt by a POY process, and preparing modified polyester DTY (Draw Textured Yarn) from the modified polyester POY by a DTY process, thereby obtaining the ultrafine-denierpolyester fiber low-stretch yarn, wherein a molecular chain of modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment, a tert-butyl side group containing diacid chain segment and a 2,5,6,6-tetramethyl-2,5-heptandiol chain segment; solid base catalyst powder subjected to high-temperature roasting is dispersed in the modified polyester. Characteristic viscosity of the prepared product is lowered by 13% to 20% after the prepared product is placed for 60 months under the condition that the temperature is 25 DEG C and the relative humidity is 65%; the dye uptake is 86.3% to 91.5% at the temperature of 123 DEG C. The preparation method disclosed by the invention is simple in process and low in cost; the prepared product is excellent in dyeing behavior, high in natural degradation rate and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com