Preparation method of high-performance bio-based water and fertilizer slow-release material

A slow-release material, bio-based technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as late research on controlled/slow-release fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

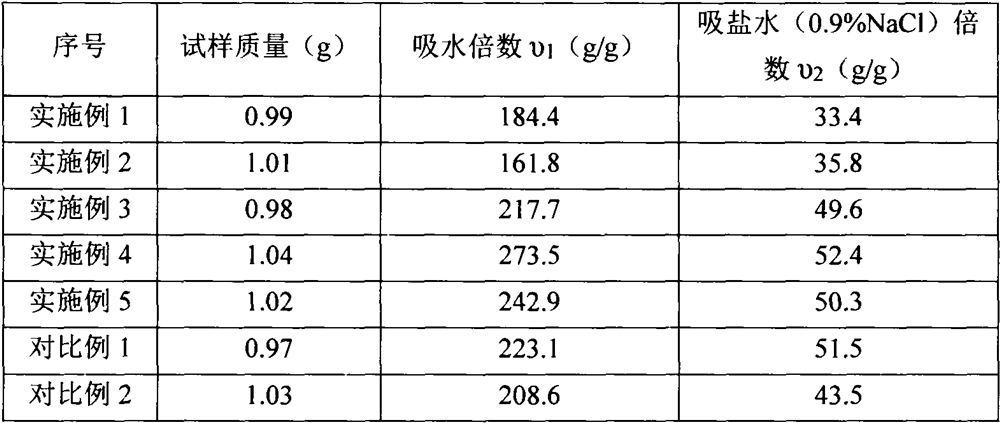

Examples

Embodiment 1

[0019] First crush 5g of corn stalks into 40-60mesh granules, add them to 50g of 10% potassium hydroxide solution under stirring conditions and react at 20°C for 100min to obtain an alkaline liquid mixture, then add 5g of kaolin to the alkali Stir in the alkaline liquid mixture for 10 minutes, and finally mix 10 g of acrylamide, humic acid, acetic acid, and ammonium persulfate at a mass ratio of 0.99:1:98:0.01 and add it to the alkaline liquid mixture, and continue the reaction at 20°C 100min. The reacted mixture is taken out, dried and dehydrated to obtain a high-performance bio-based water and fertilizer slow-release material.

Embodiment 2

[0021] 50g of soybean stalks were crushed into 120-160 mesh particles, added to 500g of sodium hydroxide solution with a mass fraction of 30% under stirring conditions and reacted at 100°C for 5min to obtain an alkaline liquid mixture, and then 50g of diatomaceous earth was added to the Stir in the alkaline liquid mixture for 1 min, and finally mix 100 g of polyacrylamide, humic acid, citric acid, and ammonium cerium nitrate in a mass ratio of 0.05:10:89:0.95 and add it to the alkaline liquid mixture. Continue to react for 1 min. The reacted mixture is taken out, dried and dehydrated to obtain a high-performance bio-based water and fertilizer slow-release material.

Embodiment 3

[0023] Crush 20g of plant stalks into 80-100mesh granules, add them to 100g of 20% sodium hydroxide solution under stirring conditions and react at 50°C for 40min to obtain an alkaline liquid mixture, then add 200g of clay to the alkaline Stir in the liquid mixture for 50 minutes, and finally mix 50 g of N,N-methylenebisacrylamide, humic acid, acrylic acid, and sodium persulfate in a mass ratio of 2:40:57:1 and add them to the alkaline liquid mixture , Continue to react at 50°C for 50min. The reacted mixture is taken out, dried and dehydrated to obtain a high-performance bio-based water and fertilizer slow-release material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com