Solid heteropoly acid-containing modified POY (Polyester) fibre and preparation method thereof

A technology of solid heteropolyacid and modified polyester, which is applied in the direction of fiber chemical characteristics, single-component polyester rayon, rayon manufacturing, etc., and can solve the problems that are also relatively large, unfavorable for polyester environmental protection production, antimony system Problems such as large amount of catalyst added to achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A kind of preparation method of the modified polyester POY fiber containing solid heteropolyacid, the steps are as follows:

[0081] (1) prepare modified polyester;

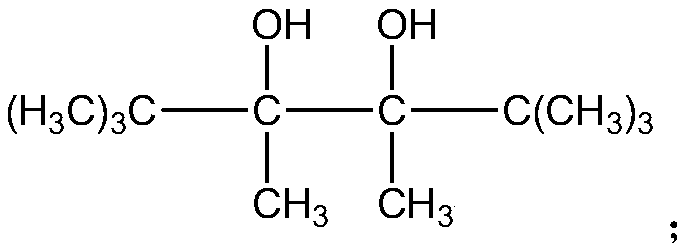

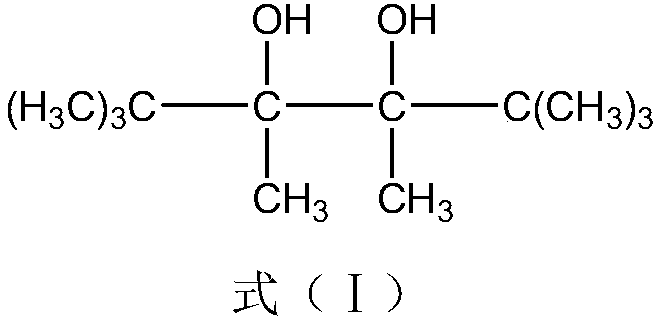

[0082] (1.1) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after mixing palladium acetate and dimethyl di-tert-butylethylene, add mass concentration It is 10% hydrogen peroxide solution, reacted at 72°C for 3 hours, cooled, crystallized and refined to obtain 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, wherein The mass ratio of dimethyldi-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:2.0:0.015, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as follows Shown in formula (I);

[0083] (1.2) Preparation of doped modified Sb 2 o 3 ;

[0084] (1.2.1) Mg(NO 3 ) 2 aqueous solution with a concentration of 8 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, the Mg in the mixture 2+ with Sb 3...

Embodiment 2

[0101] A kind of preparation method of the modified polyester POY fiber containing solid heteropolyacid, the steps are as follows:

[0102] (1) prepare modified polyester;

[0103] (1.1) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after mixing palladium acetate and dimethyl di-tert-butylethylene, add mass concentration It is 11% hydrogen peroxide solution, reacted at 70°C for 4 hours, cooled, crystallized and refined to obtain 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, wherein The mass ratio of dimethyldi-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:1.8:0.015, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as follows Shown in formula (I);

[0104] (1.2) Preparation of doped modified Sb 2 o 3 ;

[0105] (1.2.1) Ca(NO 3 ) 2 Aqueous solution with a concentration of 5 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, the Ca in the mixture 2+ with Sb 3...

Embodiment 3

[0117] A kind of preparation method of the modified polyester POY fiber containing solid heteropolyacid, the steps are as follows:

[0118] (1) prepare modified polyester;

[0119] (1.1) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after mixing palladium acetate and dimethyl di-tert-butylethylene, add mass concentration It is 12% hydrogen peroxide solution, reacted at 74°C for 4 hours, cooled, crystallized and refined to obtain 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, wherein The mass ratio of dimethyldi-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:1.6:0.015, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as follows Shown in formula (I);

[0120] (1.2) Preparation of doped modified Sb 2 o 3 ;

[0121] (1.2.1) Ba(NO 3 ) 2 Aqueous solution with a concentration of 10 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, Ba in the mixture 2+ with Sb 3+ T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com