Ultra-fine denier polyester low elastic yarn and preparation method thereof

A technology of ultra-fine denier polyester and low-elastic yarn, applied in the field of modified polyester fibers, can solve the problems of poor dyeing performance and slow natural degradation rate of ultra-fine denier polyester low-elastic yarn, so as to improve the dyeing performance and improve the dyeing performance. rate, the effect of improving the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method of ultra-fine denier polyester low elastic yarn, the steps are as follows:

[0063] (1) prepare modified polyester;

[0064] (1.1) prepare MgO powder;

[0065] First heat MgO to 400°C and keep it warm for 2 hours, then raise the temperature to 700°C and keep it warm for 1 hour, then cool it in the air, and finally pulverize it to obtain MgO powder with an average particle size of 0.49 microns;

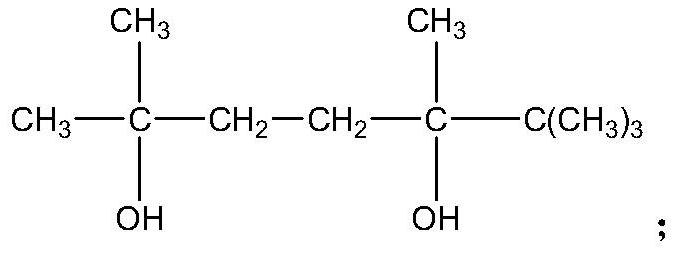

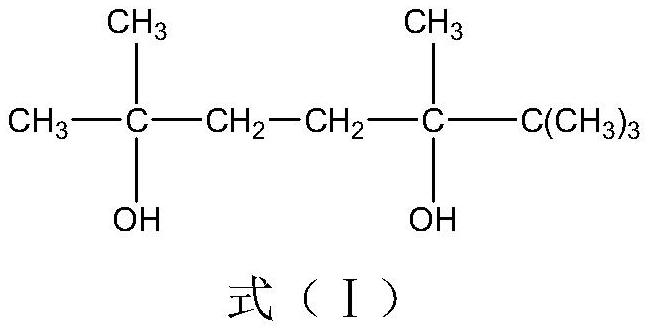

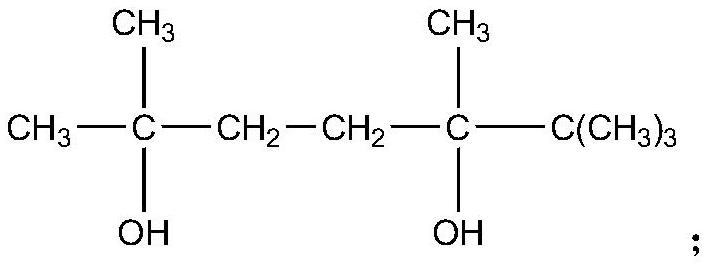

[0066] (1.2) Synthesis of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0067] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1:1:1.2:2.0, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

[0068] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 40°C for 50 minutes, continuously feed hydrogen duri...

Embodiment 2

[0083] The preparation method of ultra-fine denier polyester low elastic yarn, the steps are as follows:

[0084] (1) prepare modified polyester;

[0085] (1.1) Preparation of 2-tert-butyl-1,6-hexanedicarboxylic acid;

[0086] First, mix tungstic acid and hydrogen peroxide, stir at room temperature for 10 minutes, then add 2-tert-butylcyclohexanol and react at 80°C for 1 hour, then raise the temperature to 94°C for 2 hours. During the reaction, the reactants are always It is in a reflux state, and finally carries out cooling crystallization, washing and refining, wherein at the beginning of the reaction, the molar ratio of tungstic acid, 2-tert-butylcyclohexanol and hydrogen peroxide is 1:35:120;

[0087] (1.2) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0088] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether in a molar ratio of 1.1:1:1.2:2.3, and place in an ice bath Under the conditions of reaction for 2h, cooling crystal...

Embodiment 3

[0101] The preparation method of ultra-fine denier polyester low elastic yarn, the steps are as follows:

[0102] (1) prepare modified polyester;

[0103] (1.1) Preparation of 2-tert-butyl-1,6-hexanedicarboxylic acid;

[0104] First, mix tungstic acid and hydrogen peroxide, stir at room temperature for 12 minutes, then add 2-tert-butylcyclohexanol and react at 83°C for 1.5h, then raise the temperature to 90°C for 2h. During the reaction, the reactants Always in a reflux state, and finally carry out cooling crystallization, washing and refining, wherein at the beginning of the reaction, the molar ratio of tungstic acid, 2-tert-butylcyclohexanol and hydrogen peroxide is 1:33:120;

[0105] (1.2) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0106] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.2:1:1.25:2.0, and place in an ice bath Under the conditions of reaction for 3 hours, after the reaction is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com