Full-dull polyester low elastic yarn and preparation method thereof

A technology of fully matte polyester and low elastic yarn is applied in the field of modified polyester fibers, which can solve the problems of low processing efficiency, time-consuming and labor-intensive, environmental pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] A kind of preparation method of all-dull polyester low elastic yarn, the steps are as follows:

[0097] (1) prepare modified polyester;

[0098] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0099] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1:1:1.2:2.0, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

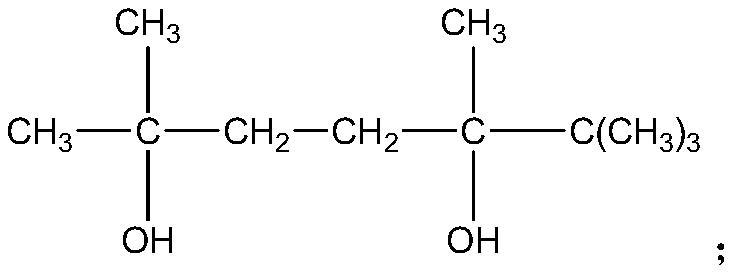

[0100] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 40°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

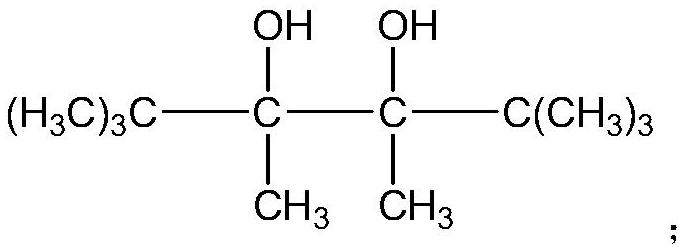

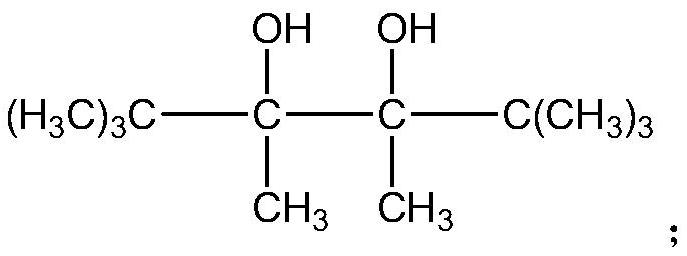

[0101] (1.2) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after ...

Embodiment 2

[0122] A kind of preparation method of all-dull polyester low elastic yarn, the steps are as follows:

[0123] (1) prepare modified polyester;

[0124] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0125] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.1:1:1.2:2.3, and place in an ice bath Under the conditions of reaction for 2h, cooling crystallization, centrifugation, washing, refining and drying are carried out after the reaction to obtain octyne diol;

[0126] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 2:10:0.01, react at a temperature of 45°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0127] (1.2) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: afte...

Embodiment 3

[0144] A kind of preparation method of all-dull polyester low elastic yarn, the steps are as follows:

[0145] (1) prepare modified polyester;

[0146] (1.1) Preparation of 2,5,6,6-tetramethyl-2,5-heptanediol;

[0147] (a) Mix KOH powder, 3-methyl-3-hydroxybutyne, 3,3-dimethyl-2-butanone and isopropyl ether at a molar ratio of 1.2:1:1.25:2.0, and place in an ice bath Under the conditions of reaction for 3 hours, after the reaction is completed, cooling and crystallization, centrifugation, washing, refining and drying are carried out to obtain octyne diol;

[0148] (b) Mix octynediol, ethanol and palladium catalyst in a weight ratio of 3:10:0.03, react at 40°C for 50 minutes, continuously feed hydrogen during the reaction, and separate and purify after the reaction to obtain 2,5,6,6-tetramethyl-2,5-heptanediol, the structural formula of 2,5,6,6-tetramethyl-2,5-heptanediol is shown in formula (I);

[0149] (1.2) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com