Environment-friendly ceramic artware and preparation method thereof

A ceramic handicraft and environmental protection technology, applied in the field of ceramic products, can solve the problems of product strength and hardness that cannot meet the use requirements, slow natural degradation rate, low waste utilization rate, etc., to achieve increased natural degradation rate, good synergy, and save production The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

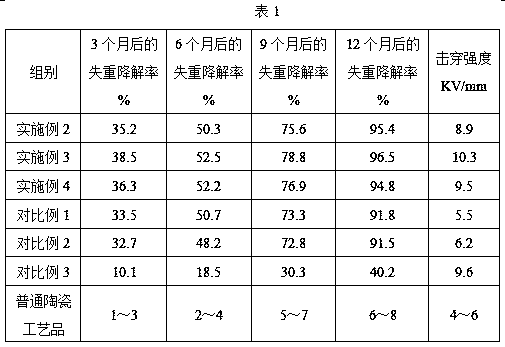

Examples

Embodiment 1

[0038] An environmentally friendly ceramic handicraft, comprising the following raw materials in parts by weight: 40-50 parts of ceramic waste, 10-20 parts of fly ash, 10-15 parts of natural clay, 5-10 parts of sludge, 5-10 parts of natural straw, clay 2-8 parts of binder, 5-10 parts of pore-forming agent, 8-15 parts of nano calcium carbonate and 5-10 parts of flux.

[0039] In this embodiment, it is preferable to include the following raw materials in parts by weight: 45 parts of ceramic waste, 15 parts of fly ash, 10 parts of natural clay, 8 parts of sludge, 8 parts of natural straw, 5 parts of binder, and 6 parts of pore-forming agent 12 parts, 12 parts of nano calcium carbonate and 7 parts of flux.

[0040] In this embodiment, the binder is preferably composed of polyvinyl alcohol with a mass fraction of 30-60% and hydroxyethyl cellulose with a mass fraction of 40-70%, and the sum of the mass fractions of the above components is 100% .

[0041] In this embodiment, the sl...

Embodiment 2

[0057] An environmentally friendly ceramic handicraft, comprising the following raw materials in parts by weight: 40 parts of ceramic waste, 10 parts of fly ash, 10 parts of natural clay, 5 parts of sludge, 5 parts of natural straw, 5 parts of binder, and 5 parts of pore-forming agent , 8 parts of nano calcium carbonate and 6 parts of flux.

[0058] In this embodiment, the binder is composed of polyvinyl alcohol with a mass fraction of 30% and hydroxyethyl cellulose with a mass fraction of 70%.

[0059] In this example, the sludge is composed of humic sludge with a mass fraction of 80% and activated sludge with a mass fraction of 20%.

[0060] In this embodiment, the pore-forming agent is composed of carbon powder with a mass fraction of 20% and sodium carbonate powder with a mass fraction of 80%.

[0061] In this embodiment, the flux is a combination of limestone, calcite and diopside.

[0062] In this embodiment, the ceramic waste is ceramic scrap.

[0063] In this embodi...

Embodiment 3

[0075] An environmentally friendly ceramic handicraft, comprising the following raw materials in parts by weight: 45 parts of ceramic waste, 15 parts of fly ash, 10 parts of natural clay, 8 parts of sludge, 8 parts of natural straw, 5 parts of binder, and 6 parts of pore-forming agent , 12 parts of nano calcium carbonate and 7 parts of flux.

[0076] In this embodiment, the binder is composed of polyvinyl alcohol with a mass fraction of 60% and hydroxyethyl cellulose with a mass fraction of 40%.

[0077] In this example, the sludge is composed of humic sludge with a mass fraction of 80% and activated sludge with a mass fraction of 20%.

[0078] In this embodiment, the pore-forming agent is composed of carbon powder with a mass fraction of 30% and sodium carbonate powder with a mass fraction of 70%.

[0079] In this embodiment, the flux is a combination of limestone, calcite and diopside.

[0080] In this embodiment, the ceramic waste is a combination of ceramic polishing was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com