A kind of degradable polyester fiber and preparation method thereof

A technology for degrading polyester and fiber, applied in the field of polyester fiber, can solve the problem that polyester fiber cannot be recycled, and achieve the effect of excellent degradable performance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

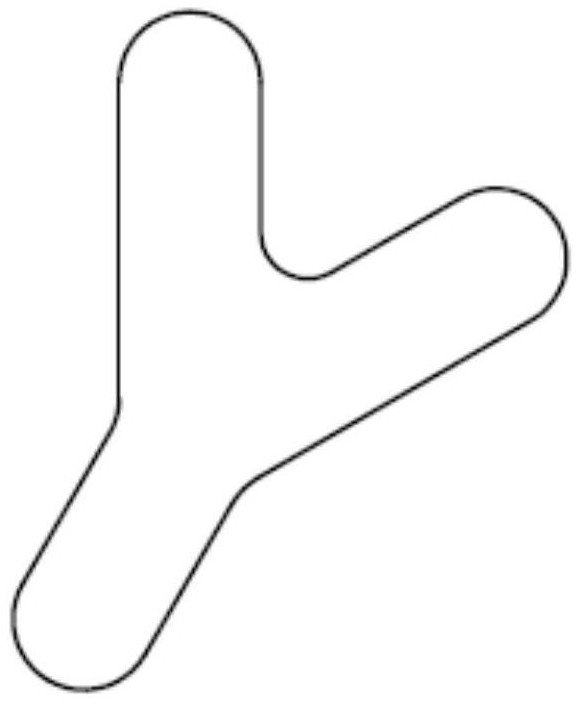

[0039] A preparation method of degradable polyester fiber, extruding PET melt with an intrinsic viscosity of 0.6dL / g from the three-lobed spinneret hole on the spinneret and cooling it with ring blowing, and making FDY yarn according to the FDY process , and then the degradable polyester fiber is obtained through relaxation heat treatment;

[0040] 0.03wt% doped modified ZrO dispersed in PET melt 2 , the process of doping modification is as follows: firstly, the concentration of 1wt% Mg(NO 3 ) 2 aqueous solution with a concentration of 20wt% ZrO 2 Nitric acid solution is mixed evenly, and then the ammoniacal liquor of concentration 2mol / L is added dropwise to the pH value of mixed solution to be 9 (when precipitation starts, Mg in mixed solution 2+ with Zr 4+ The molar ratio is 5:100), and finally the precipitated product is calcined (the precipitated product is washed and dried before the calcination, the drying temperature is 105°C, and the time is 2h), the calcining pro...

Embodiment 2

[0046] A preparation method of degradable polyester fiber, extruding PET melt with an intrinsic viscosity of 0.62dL / g from the three-lobed spinneret hole on the spinneret and cooling it by ring blowing, and making FDY yarn according to the FDY process , and then the degradable polyester fiber is obtained through relaxation heat treatment;

[0047] 0.03wt% doped modified ZrO dispersed in PET melt 2 , the process of doping modification is as follows: firstly, the concentration of 1wt% Mg(NO 3 ) 2 aqueous solution with a concentration of 21wt% ZrO 2 Nitric acid solution is mixed evenly, and then the ammoniacal liquor of concentration 2mol / L is added dropwise to the pH value of mixed solution to be 9 (when precipitation starts, Mg in mixed solution 2+ with Zr 4+ The molar ratio is 8:100), and finally the precipitated product is calcined (the precipitated product is washed and dried before calcination, the drying temperature is 105°C, and the time is 2h). 3h, then heat up to 7...

Embodiment 3

[0053] A preparation method of degradable polyester fiber, extruding PET melt with an intrinsic viscosity of 0.61dL / g from the three-lobed spinneret hole on the spinneret and then cooling it by ring blowing, and making FDY yarn according to the FDY process , and then the degradable polyester fiber is obtained through relaxation heat treatment;

[0054] 0.03wt% doped modified ZrO dispersed in PET melt 2 , the process of doping modification is as follows: firstly, LiNO with a concentration of 1wt% 3 aqueous solution with a concentration of 25wt% ZrO 2 The nitric acid solution is mixed evenly, and then the ammoniacal liquor of concentration 2mol / L is added dropwise to the pH value of mixed solution to be 9 (when precipitation starts, Li in mixed solution + with Zr 4+ The molar ratio is 5:100), and finally the precipitated product is calcined (the precipitated product is washed and dried before the calcination, the drying temperature is 105°C, and the time is 2h), the calcining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com