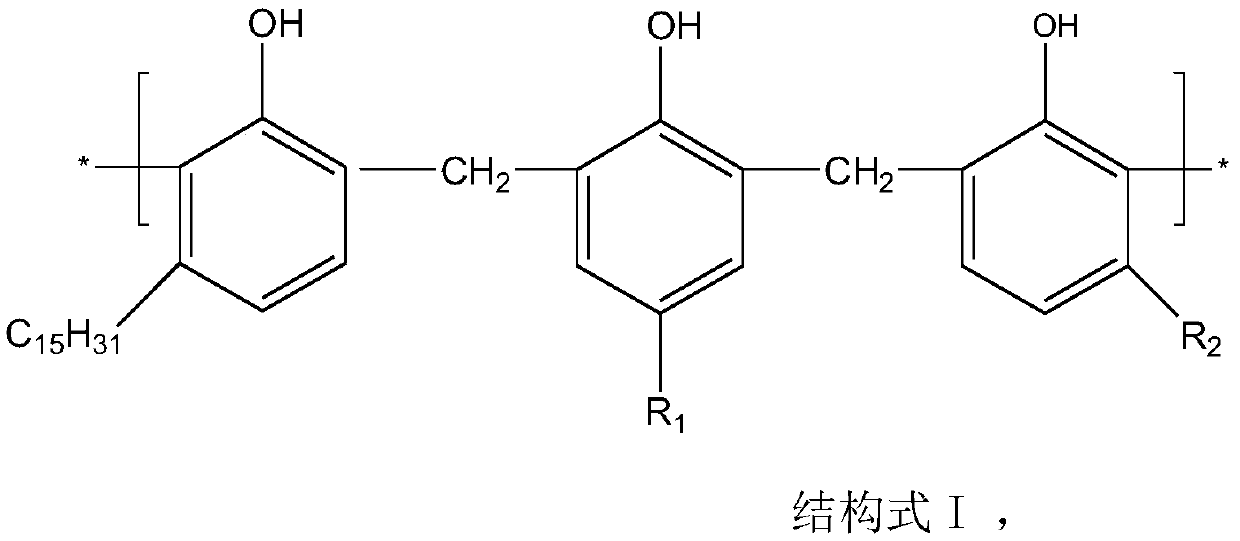

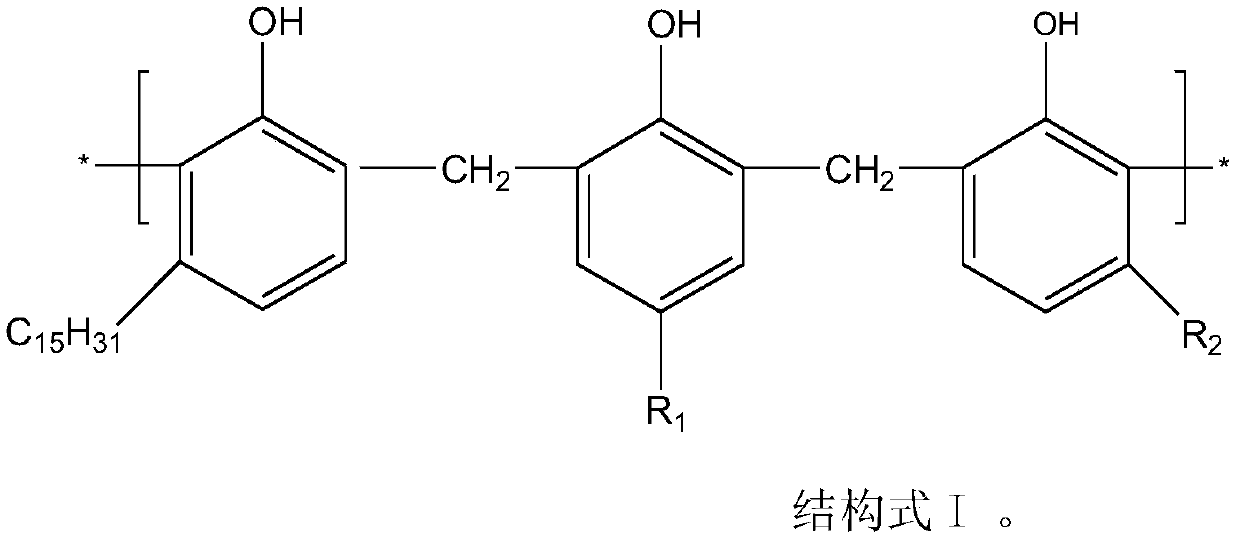

3-pentadecyl-phenol phenolic resin as well as preparation method and application thereof

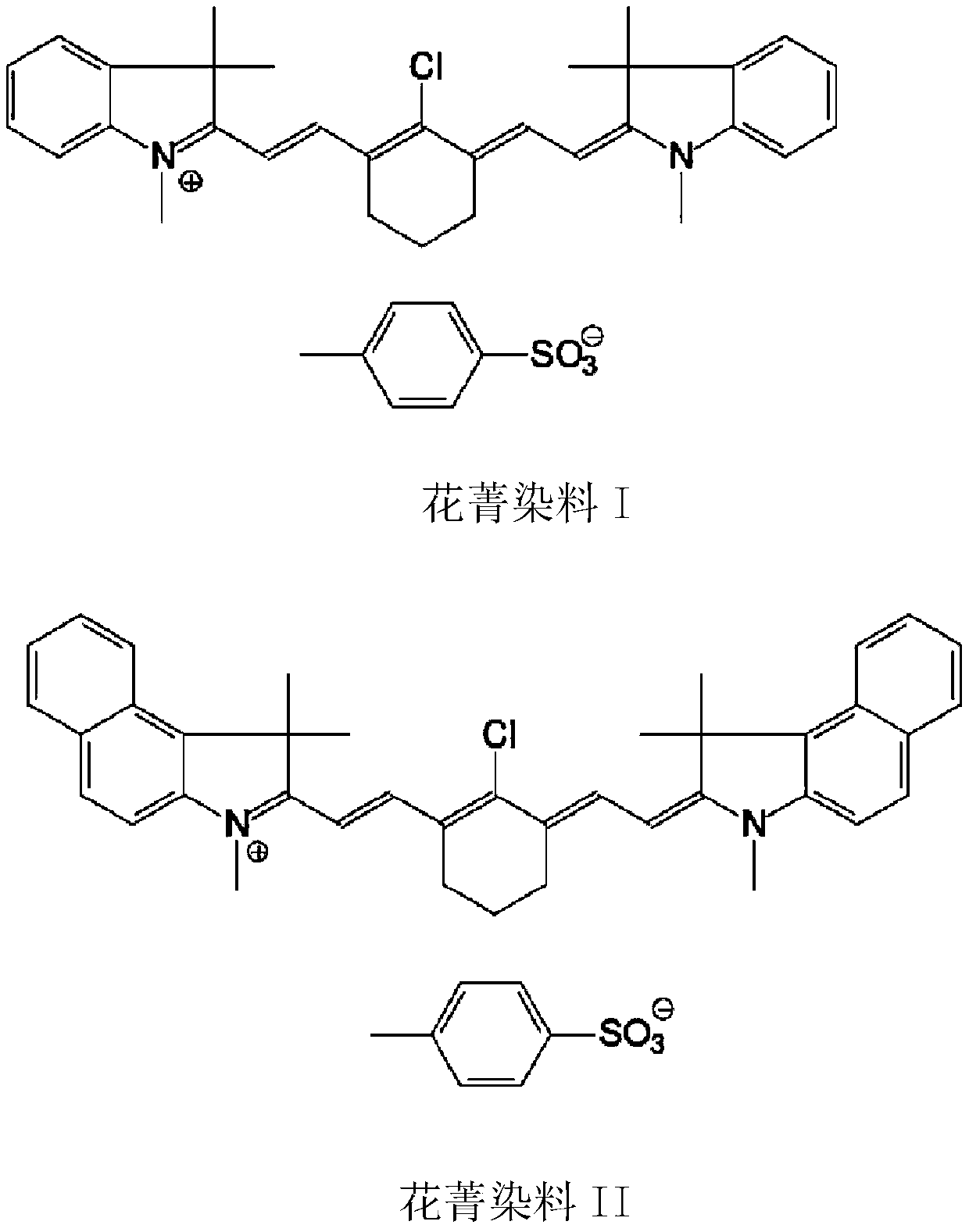

A technology of pentadecylphenol and phenolic resin, which is applied in the direction of photosensitive materials used in optomechanical equipment, etc., and can solve the problems of low sensitivity and poor solubility of the composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0057] Embodiment 1-10 is the specific synthetic example of special phenolic resin:

Embodiment 1

[0058] The synthesis of the pentadecylphenol type phenolic resin (P1) between embodiment 1

[0059] In a four-necked flask equipped with a stirrer and a thermometer, put 142g of m-pentadecylphenol, 22g of phenol, 25g of m-cresol, 25g of p-cresol, 1g of oxalic acid and 50g of formaldehyde solution with a mass of 37%, heat up, stir and heat The mixture was refluxed for 30min. Add 1 gram of oxalic acid and continue to reflux for 1 hour. After cooling, let stand for 30 minutes to siphon out the upper layer of water, then vacuum distill and heat to raise the temperature in the bottle to 120°C to obtain m-pentadecylphenol-type phenolic resin (P1). 208g. The GPC measurement results of the phenolic resin (P1) are: the number average molecular weight (Mn) is 2825, the weight average molecular weight (Mw) is 7680, and the polydispersity index (Mw / Mn)=2.719.

Embodiment 2

[0060] The synthesis of the pentadecylphenol type phenolic resin (P2) between embodiment 2

[0061] In a four-necked flask equipped with a stirrer and a thermometer, 160 g of m-pentadecylphenol, 20 g of phenol, 17 g of p-cresol, 17 g of m-cresol, 4 grams of zinc acetate, 50 g of aqueous formaldehyde solution of 37% quality and 1 g of oxalic acid were added. 0.5g of p-toluenesulfonic acid, stirred and heated the mixture, and refluxed for 30min. Add 1 gram of oxalic acid, and continue to reflux for 1 hour. After cooling, let stand for 30 minutes to siphon out the upper layer of water, and then vacuum distill and heat to raise the temperature in the bottle to 120°C to obtain m-pentadecylphenol-type phenolic resin (P2). 190g. The GPC measurement results of the phenolic resin (P2) are: the number average molecular weight (Mn) is 5080, the weight average molecular weight (Mw) is 11630, and the polydispersity index (Mw / Mn)=2.289.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com