Platinoid bi-component catalyst as well as preparation method and application thereof

A catalyst, two-component technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Reduce the propylene yield and other problems, and achieve the effects of uniform distribution, high propane conversion, and good propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

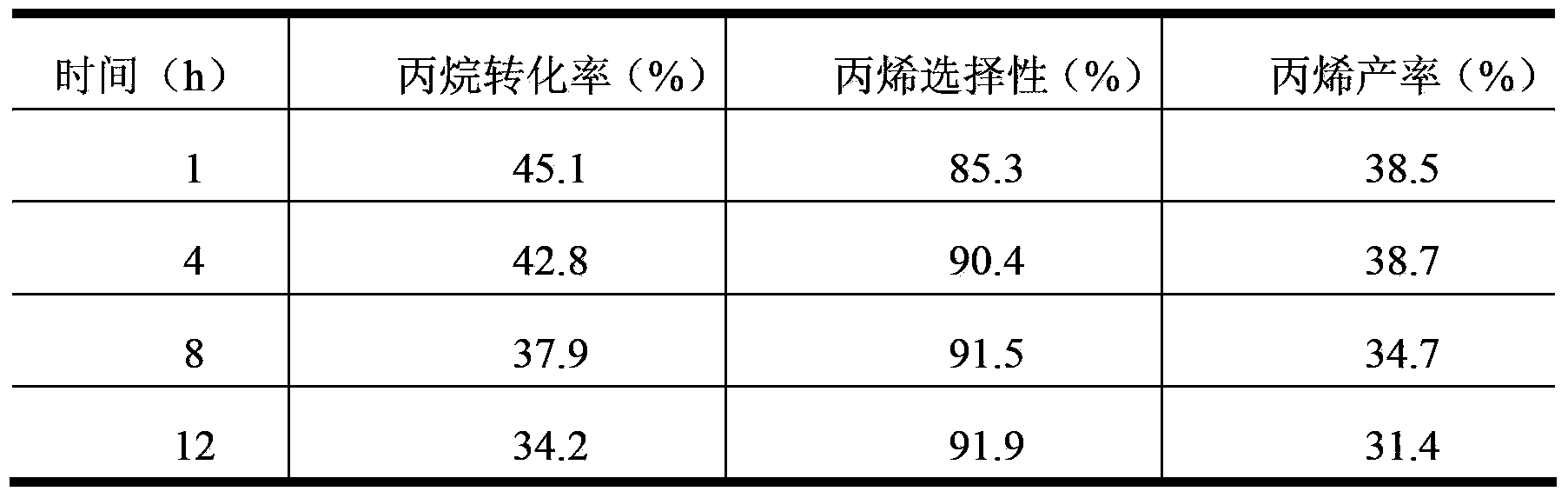

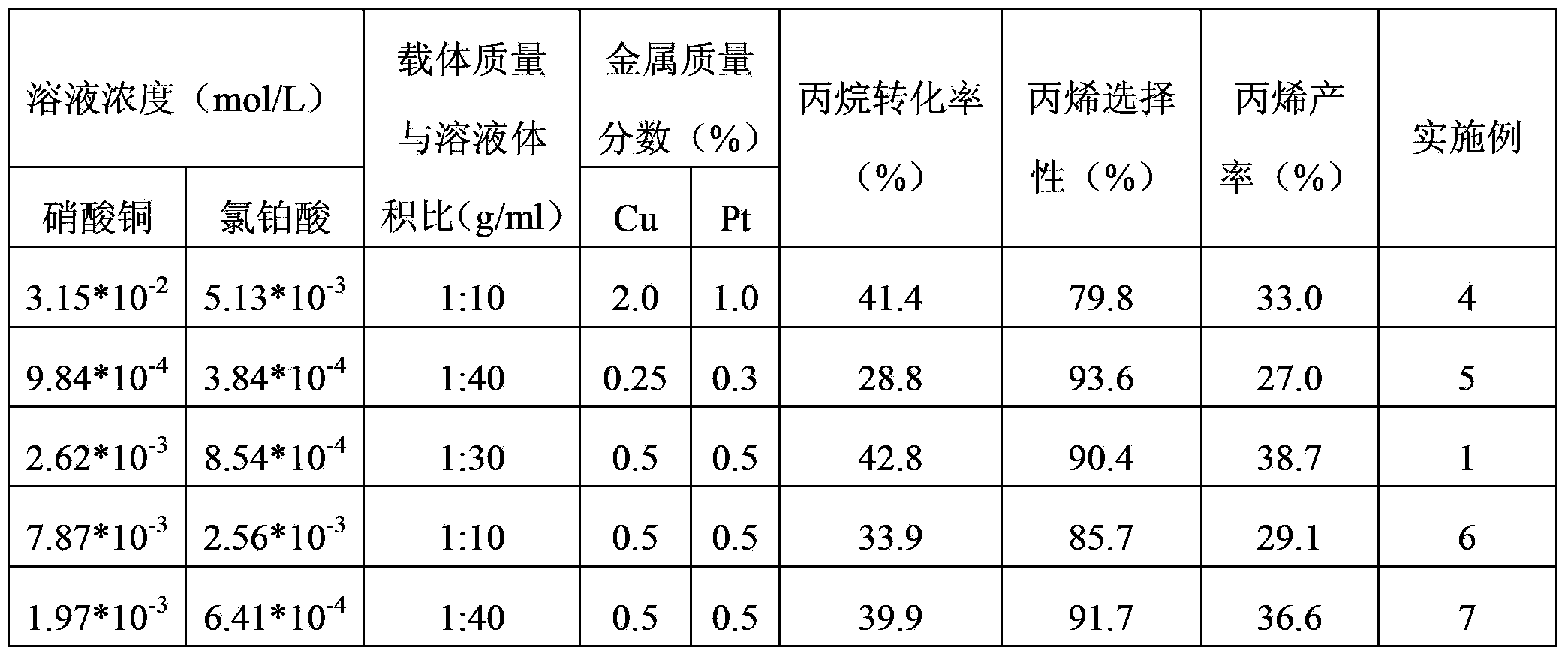

Embodiment 1

[0027] (1) The carrier γ-Al 2 o 3 The powder is placed at 2.62*10 at 60°C -3 Cu(NO 3 ) 2 Immerse in the aqueous solution for 6h, the ratio of carrier mass to solution volume is 1g:30ml;

[0028] (2) The eggplant-shaped bottle is connected to a rotary evaporator, and the rotary evaporator is connected to a vacuum pump. The solvent water is removed by a rotary evaporator under reduced pressure, dried at 120°C for 12 hours, and roasted at 550°C for 4 hours to obtain a copper-supported catalyst powder;

[0029] (3) At 60°C, place the prepared copper-supported catalyst powder at 8.54*10 -4 M of H 2 PtCl 6 Immerse in the aqueous solution for 6 hours, the ratio of the mass of the carrier to the volume of the solution is 1g:30ml;

[0030] (4) The eggplant-shaped bottle is connected to a rotary evaporator, and the rotary evaporator is connected to a vacuum pump. The solvent water is removed by a rotary evaporator under reduced pressure, dried at 120°C for 12 hours, and roasted at ...

Embodiment 2

[0040] The method in Example 1 was used for the reaction, the only difference being that the immersion temperatures of step (1) and step (3) were both 40°C.

Embodiment 3

[0042] The method of Example 1 was used for the reaction, the only difference being that the immersion temperatures of step (1) and step (3) were both 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com