Double-component orange slice type compound fibers and preparation method thereof

A segmented orange-shaped, composite fiber technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of long natural degradation time, limit the application of chemical degradation and recycling, and achieve the increase of free volume of voids, specific The effect of increasing the surface area and increasing the free volume of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A kind of preparation method of two-component segmented orange type composite fiber, its specific steps are as follows:

[0073] (1) prepare modified polyester;

[0074] (1.1) Preparation of doped modified Bi 2 o 3 Powder;

[0075] (1.1.1) The concentration of 2.5wt% Ca(NO 3 ) 2 Aqueous solution with concentration of 22wt% Bi 2 o 3 The solution is mixed evenly, Bi 2 o 3 The solvent of the solution is nitric acid, the Ca in the mixture 2+ with Bi 3+ The mol ratio is 7:100;

[0076] (1.1.2) Add dropwise ammonia water with a concentration of 2 mol / L until the pH value of the mixed solution is 10 to obtain a precipitated product, wash and dry the precipitated product at a temperature of 105°C for 2.5 hours;

[0077] (1.1.3) Heat the dried product to 400°C and keep it warm for 2.5h, then heat it up to 700°C and keep it warm for 1.5h, and finally cool it in air and pulverize it to obtain doped modified Bi with an average particle size of 0.45 microns 2 o 3 Powder...

Embodiment 2

[0101] A kind of preparation method of two-component segmented orange type composite fiber, its specific steps are as follows:

[0102] (1) prepare modified polyester;

[0103] (1.1) Preparation of 3-trimethylsilyl-3-methyl-1,2-propanediol;

[0104] (1.1) Mix 3-trimethylsilyl-3-methylpropene, peracetic acid and dichloromethane at a molar ratio of 1:5:10, and react at a temperature of 35°C for 5 hours with stirring during the reaction. After the end, the solvent is removed, and trimethylsilylpropylene epoxide is obtained through purification and refining;

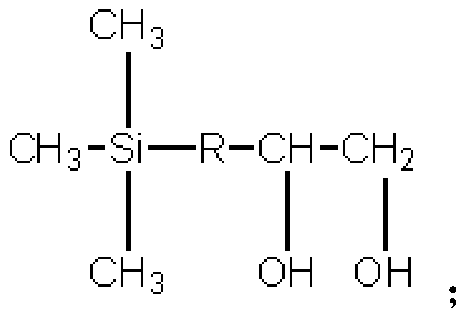

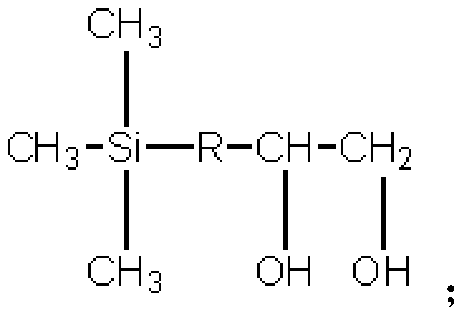

[0105] (1.2) Mix water, concentrated sulfuric acid and trimethylsilyl propylene epoxide, heat it in a water bath to 80°C under stirring conditions, keep it warm for 10 minutes, cool to room temperature after the reaction, and obtain such as 3-trimethylsilyl-3-methyl-1,2-propanediol shown in formula (I), R in formula (I) is -CH(CH 3 )-, concentrated sulfuric acid is the sulfuric acid that mass concentration is 70%, when re...

Embodiment 3

[0119] A kind of preparation method of two-component segmented orange type composite fiber, its specific steps are as follows:

[0120] (1) prepare modified polyester;

[0121] (1.1) Preparation of 3-trimethylsilyl-3-methyl-1,2-propanediol;

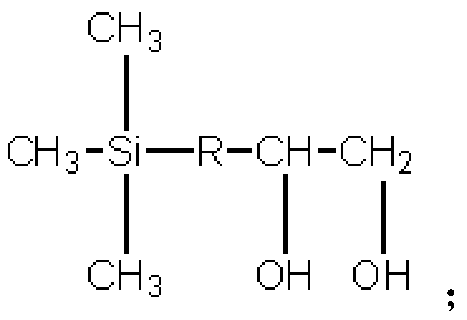

[0122] (1.1.1) Mix 3-trimethylsilyl-3-methylpropene, peracetic acid and dichloromethane at a molar ratio of 1:10:15, and react at a temperature of 40°C for 8 hours with stirring , the solvent is removed after the reaction, and trimethylsilylpropylene epoxide is obtained through purification and refinement;

[0123] (1.1.2) Mix water, concentrated sulfuric acid and trimethylsilyl propylene epoxide, heat it in a water bath to 85°C under stirring conditions, keep it warm for 15 minutes, cool to room temperature after the reaction, neutralize, distill, separate and purify Obtain 3-trimethylsilyl-3-methyl-1,2-propanediol as shown in formula (I), R in formula (I) is-CH(CH 3 )-, concentrated sulfuric acid is the sulfuric acid that mass concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com