System for preparing recycled aggregate from waste concrete on basis of particle impact crushing

A technology for waste concrete and recycled aggregate, which is applied in solid waste management, sustainable waste treatment, grain treatment, etc. The effect of a large amount of sandblasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In this example, the concrete block is waste concrete from construction waste, and after screening, it does not contain impurities such as steel bars, wood, and rubber. By adopting the aggregate regeneration system of the present invention, the aggregate and cement mortar of waste concrete can be completely separated efficiently. The present invention will be further described below through specific embodiments.

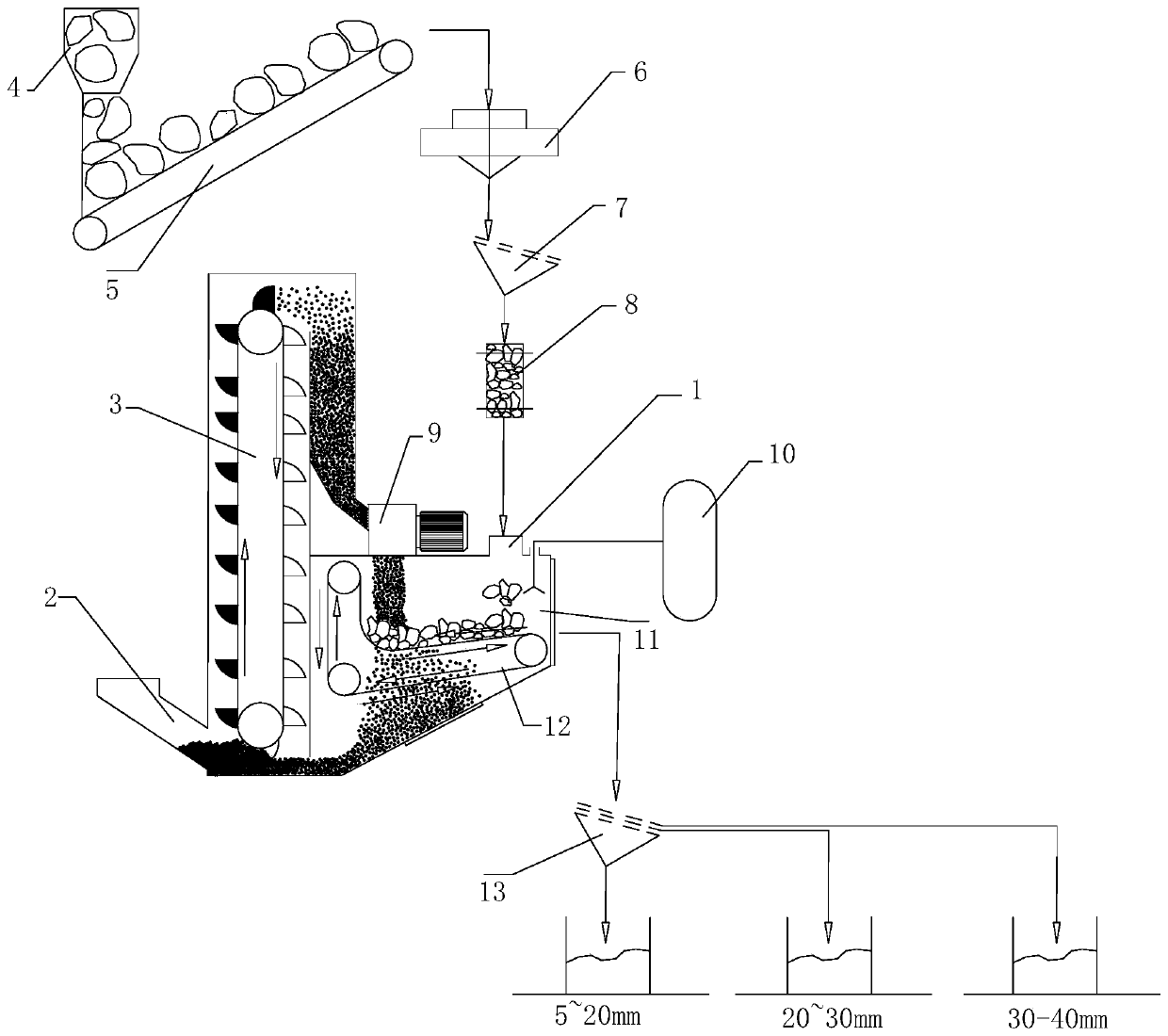

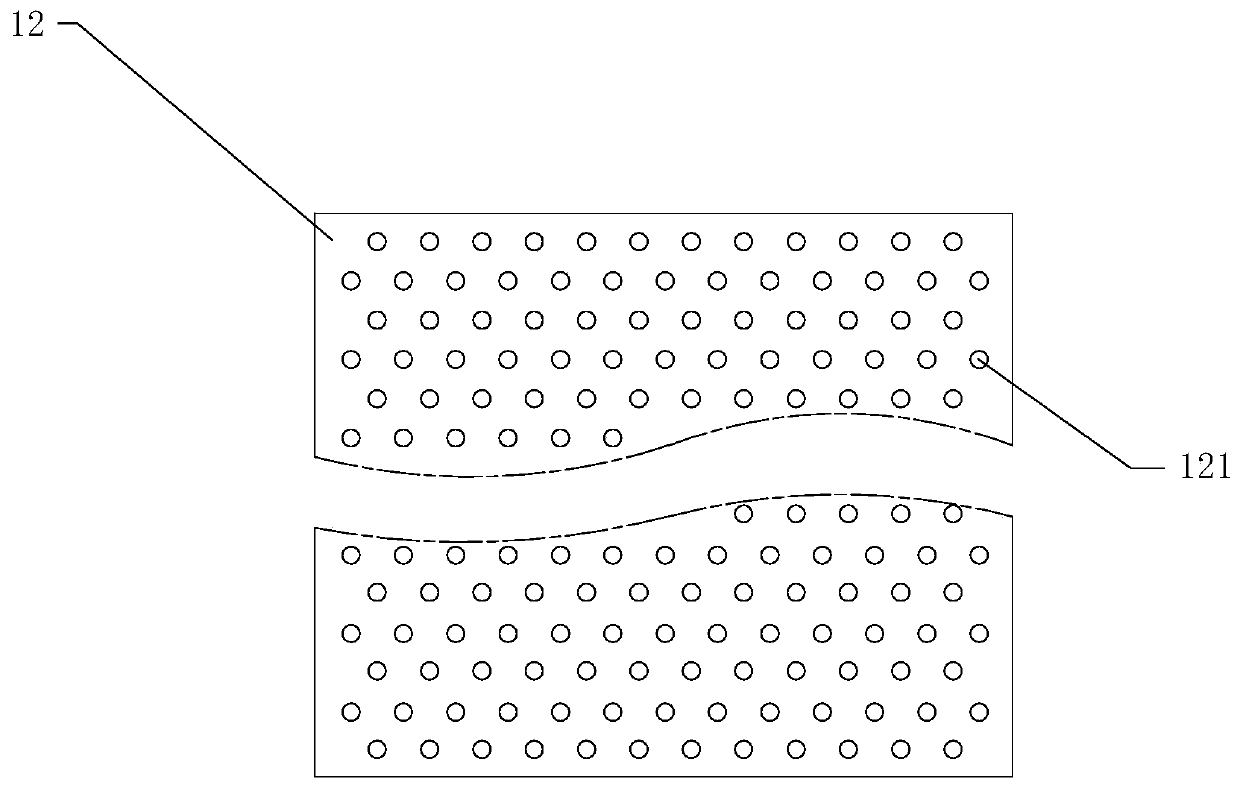

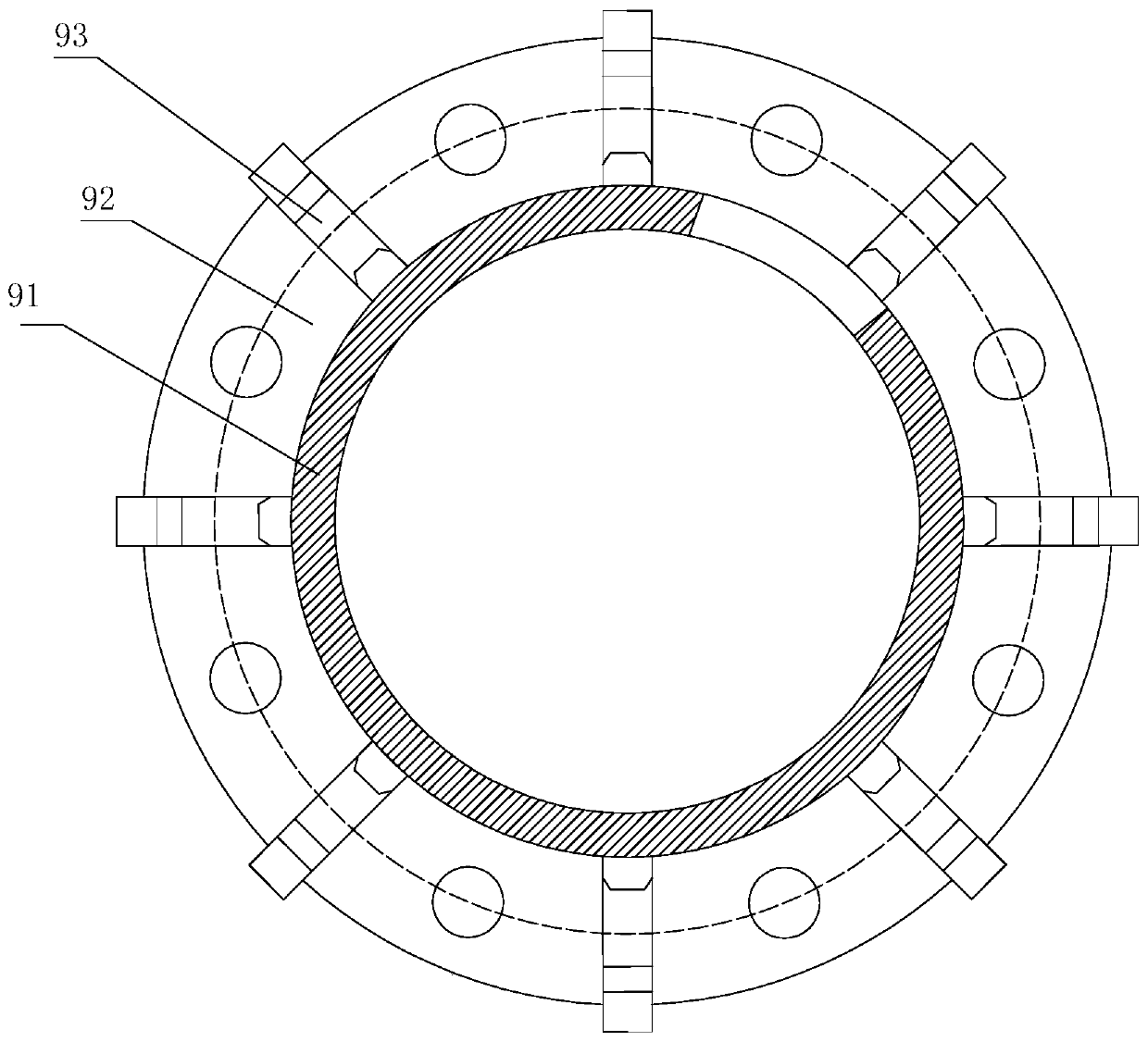

[0028] figure 1 It is a schematic structural diagram of a system for preparing recycled aggregates based on particle impact crushed waste concrete, which includes: a first inlet 1, a second inlet 2, a lifting device 3, a silo 4, a conveyor belt 5, a crusher 6, The first vibrating screen 7, the heating furnace 8, the particle accelerator 9, the dust collector 10, the spray grinding chamber 11, the crawler belt 12, and the second vibrating screen 13.

[0029] The silo 4 is used to store concrete blocks with a particle size greater than 40mm after primary crushing. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com