Coarse particle polycrystalline diamond synthesizing technology

A technology of polycrystalline diamond and synthesis process, which is applied in the application of ultra-high pressure process, etc., can solve the problems of low impact toughness, poor thermal stability, and low yield of polycrystalline diamond, and achieve irregular shape, rough surface, and impurities little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

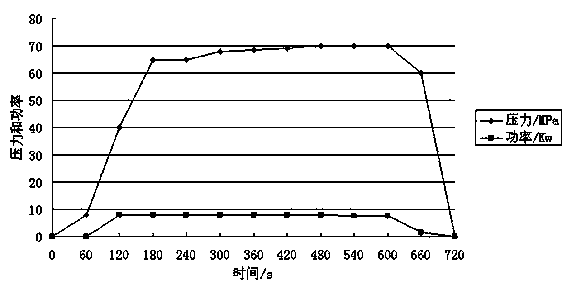

[0018] like figure 1 The synthetic process of coarse-grained polycrystalline diamond shown comprises the following steps:

[0019] 1) Put the synthetic block into the press;

[0020] 2), Boost to 8MPa within 0~60s;

[0021] 3) Boost the pressure from 8MPa to 40MPa within 60s~120s, and increase the heating power from 0 to 8kw at the same time;

[0022] 4) Slowly increase the pressure from 40MPa to 65MPa within 120s~180s, then keep the pressure for 60s, and keep the heating power at 8kw for 240s;

[0023] 5) Slowly increase the pressure from 65MPa to 70MPa within 240s ~ 480s, and then hold the pressure for 120s; slowly reduce the heating power from 8kw to 7.6kw within 360s ~ 600s;

[0024] 6) The pressure is reduced from 70MPa to 60MPa within 600s~660s, and the heating power is suddenly dropped from 7.6kw to 1.5kw;

[0025] 7) Step down the pressure and reduce the heating power to 0 within 660s~720s, and then cool down for 400s;

[0026] 8) Take out the synthetic block.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com