cBN-high speed steel composite material and preparation method thereof

A technology of composite materials and high-speed steel, applied in the field of cBN, can solve problems such as high sintering temperature and cBN erosion, achieve excellent pressing performance, prevent powder segregation, and get rid of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

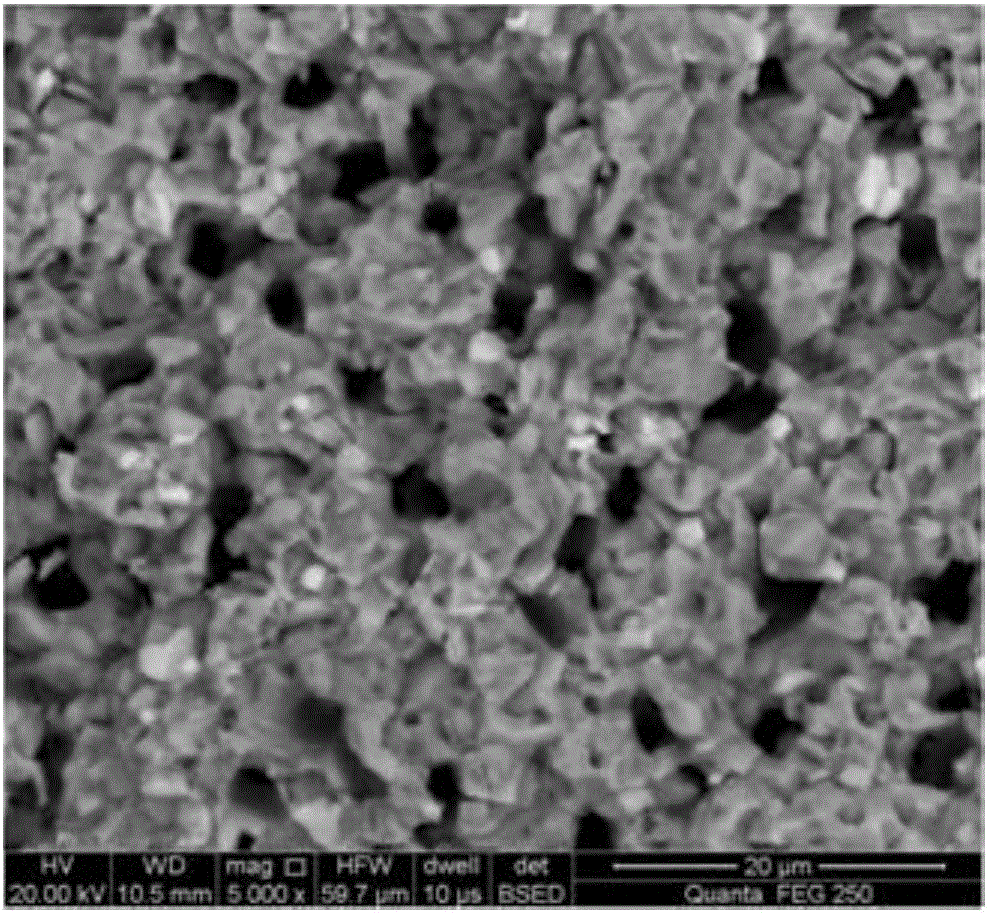

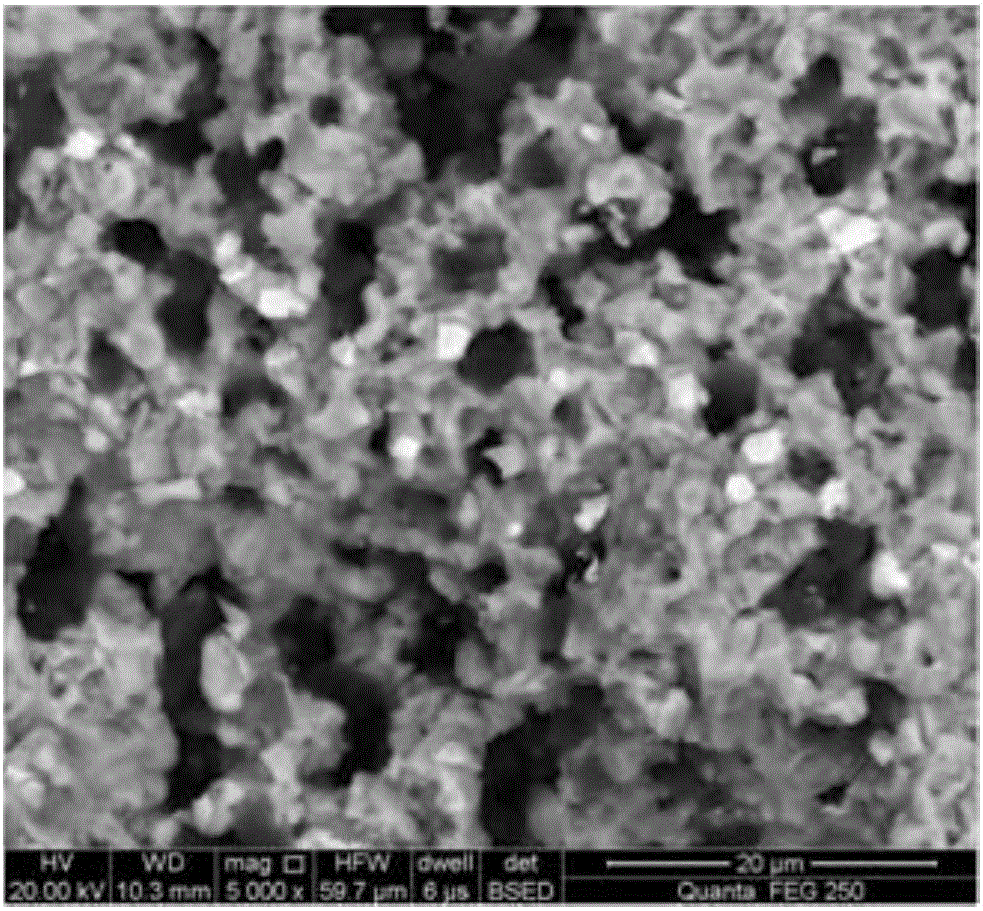

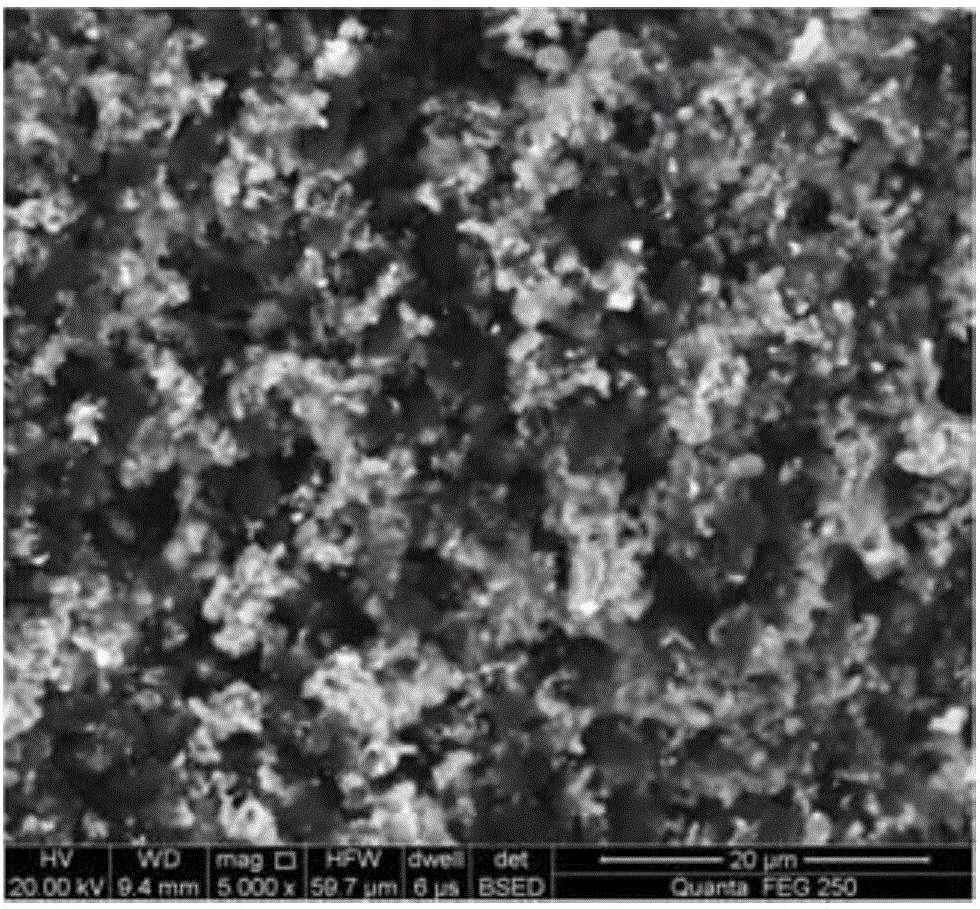

Image

Examples

Embodiment Construction

[0032] Beneficial effects of the present invention will be further described below by way of examples.

[0033] The difference between Examples 1-5 is only that: the proportioning ratio of the high-speed steel precursor powder mixture is different, and correspondingly the composition of the cBN-high-speed steel composite material is also different; the difference between Examples 3 and 6-9 is only that: the high-speed steel The proportion of carbides in the precursor powder mixture is different, and correspondingly the composition of the cBN-high-speed steel composite material is also different; the difference between Examples 3 and 10-13 is only: the cBN-high-speed steel composite material precursor powder mixture The proportions are different, and correspondingly the composition of the cBN-high-speed steel composite material is also different; see Table 3 for details, wherein the carbide powder is composed of WC powder, Mo 2 C powder, Cr 3 C 2 powder and VC powder, WC powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com