High strength and toughness deformation magnesium alloy and preparation method thereof

A technology for deforming magnesium alloys and magnesium alloys, applied in the field of magnesium alloys, can solve problems such as increasing costs, and achieve the effects of improving corrosion resistance, alloy plasticity, and room temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention proposes a method for preparing a high-strength toughness deformed magnesium alloy, which includes the following preparation steps:

[0039] Steps to dose ingredients by target;

[0040] According to mass percentage, adopt industrial pure aluminum (Al), industrial pure zinc (Zn), Mg-20Ca master alloy and Mg-5Mn master alloy and industrial pure magnesium (Mg) to carry out batching, obtain first raw material and second raw material respectively, stand-by;

[0041] The first raw material is industrial pure magnesium (Mg);

[0042] The second raw material is industrial pure aluminum (Al), industrial pure zinc (Zn), Mg-20Ca master alloy and Mg-5Mn master alloy;

[0043] the step of melting the ingot;

[0044] Step 21, preheat the crucible; place the graphite crucible in a resistance furnace, raise the temperature to 320°C-350°C at a heating rate of 5°C-10°C / min, keep it warm for 10-20min, and evenly sprinkle the first RJ- 6 materials; the mass perce...

Embodiment 1

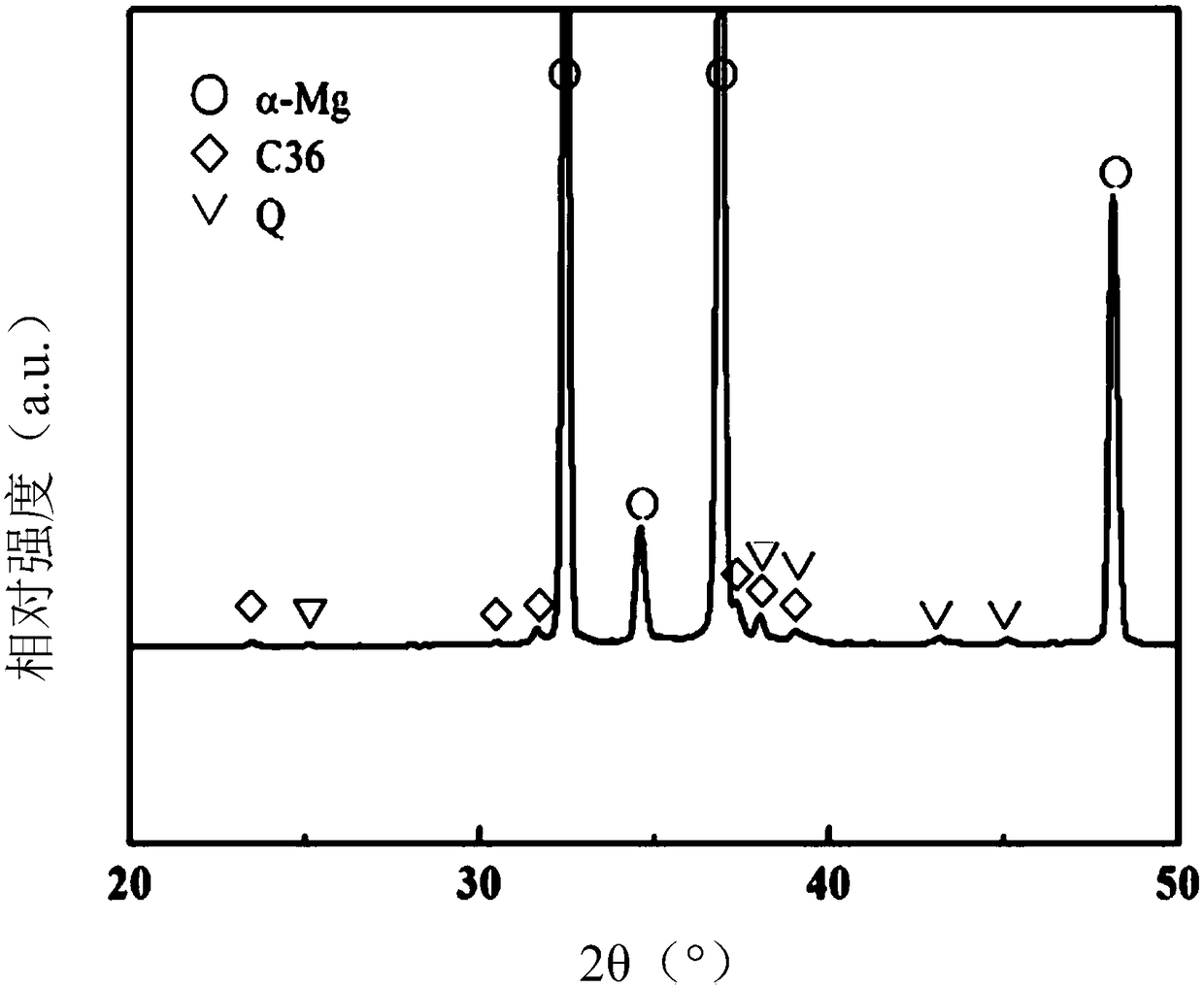

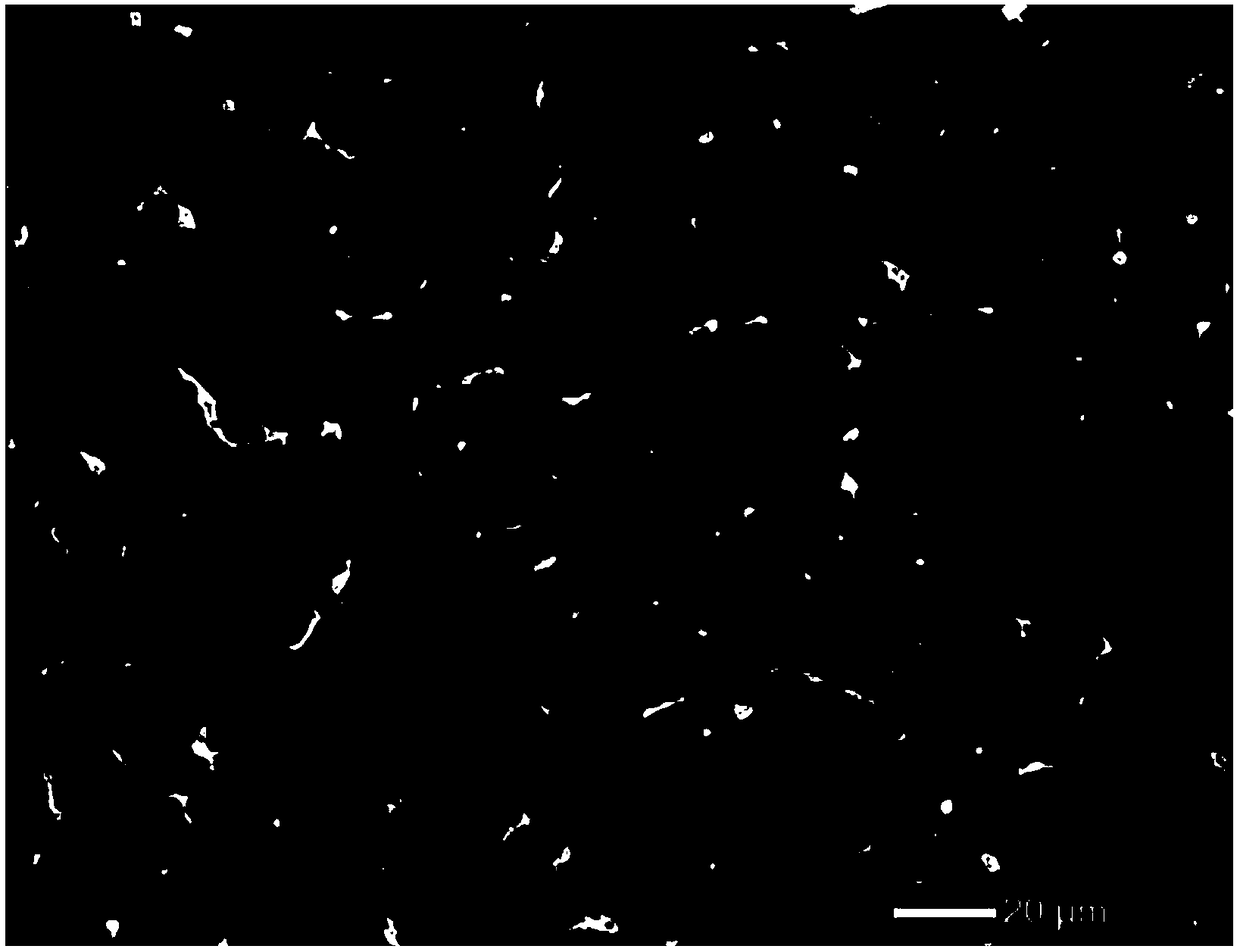

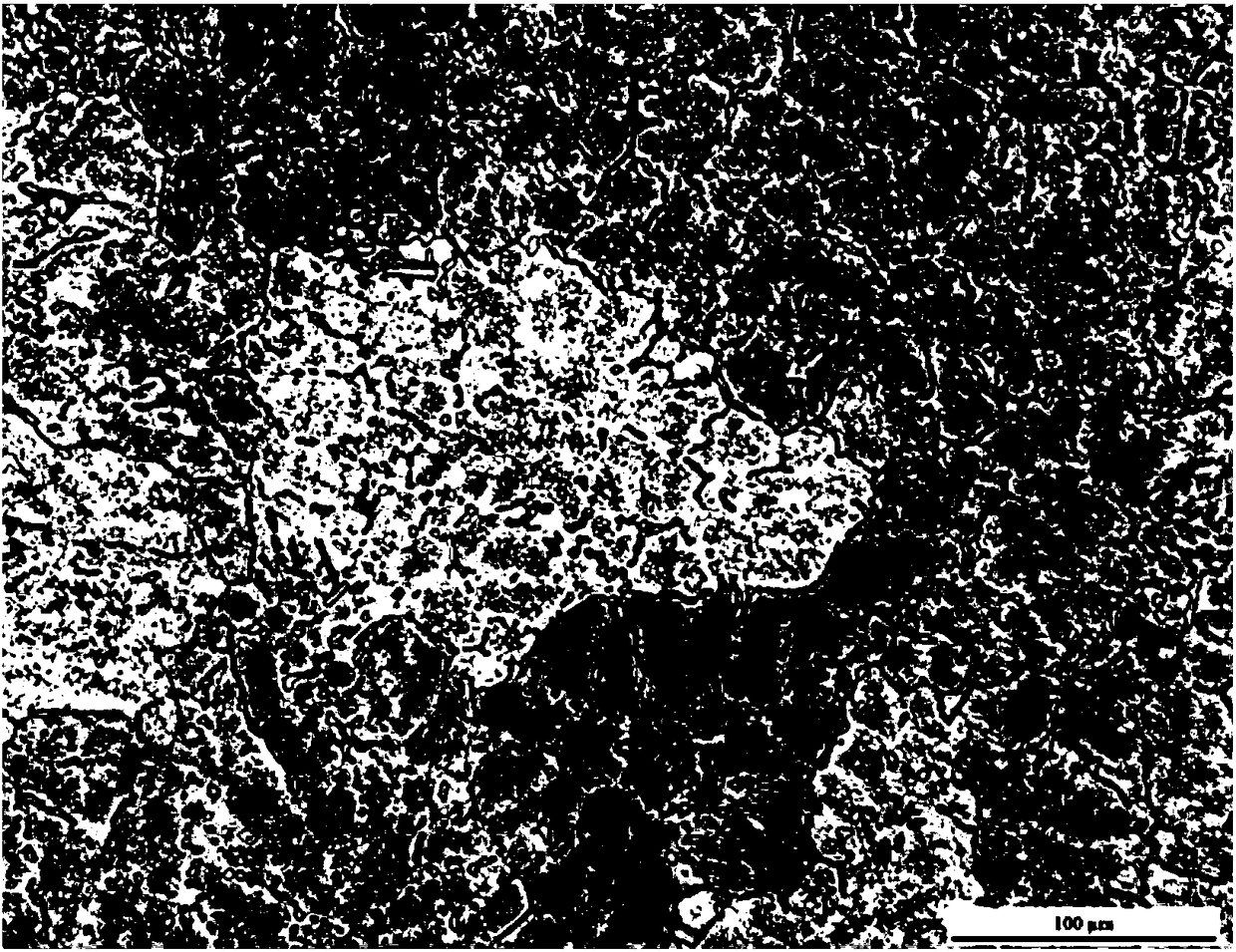

[0059] Preparation of heat treatable strengthened Mg-4Al-4Zn-2Ca-0.4Mn high-strength wrought magnesium alloy in which the Mg-Al-Ca phase of solid solution Zn is the main reinforcing phase, and its target composition and mass percentage are: Al 4%, Zn 4% , Ca 2%, Mn 0.4% and the balance is Mg, the total mass is 100%.

[0060] The method for preparing Mg-4Al-4Zn-2Ca-0.4Mn high-strength wrought magnesium alloy is as follows:

[0061] Steps to dose ingredients by target;

[0062] According to mass percentage, industrial pure aluminum (Al), industrial pure zinc (Zn), Mg-20Ca master alloy (produced by Wenxi County Xinglin Nonferrous Metal Materials Co., Ltd.) and Mg-5Mn master alloy (selected from Wenxi County Xinglin Lin Nonferrous Metal Materials Co., Ltd.) and commercially pure magnesium (Mg) are batched, and the first raw material and the second raw material are obtained respectively, and are for use;

[0063] The first raw material is industrial pure magnesium (Mg);

[0064]...

Embodiment 2

[0079] Preparation of heat treatable strengthened Mg-6Al-4Zn-3Ca-0.4Mn high-strength wrought magnesium alloy in which the Mg-Al-Ca phase of solid solution Zn is the main reinforcing phase, and its target composition and mass percentage are: Al 6%, Zn 4% , Ca 3%, 0.4% Mn and the balance is Mg, the total mass is 100%.

[0080] The method for preparing Mg-6Al-4Zn-3Ca-0.4Mn high-strength wrought magnesium alloy is as follows:

[0081] Steps to dose ingredients by target;

[0082] According to mass percentage, adopt industrial pure aluminum (Al), industrial pure zinc (Zn), Mg-20Ca master alloy, Mg-5Mn master alloy and industrial pure magnesium (Mg) to carry out batching, obtain first raw material and second raw material respectively, stand-by;

[0083] The first raw material is industrial pure magnesium (Mg);

[0084] The second raw material is industrial pure aluminum (Al), industrial pure zinc (Zn), Mg-20Ca master alloy and Mg-5Mn master alloy;

[0085] the step of melting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com