A kind of platinum/cerium oxide@silica porous catalyst and its preparation method

A porous catalyst, catalyst technology, used in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. Affecting catalytic activity and other problems, to achieve the effect of enriching preparation methods, good stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

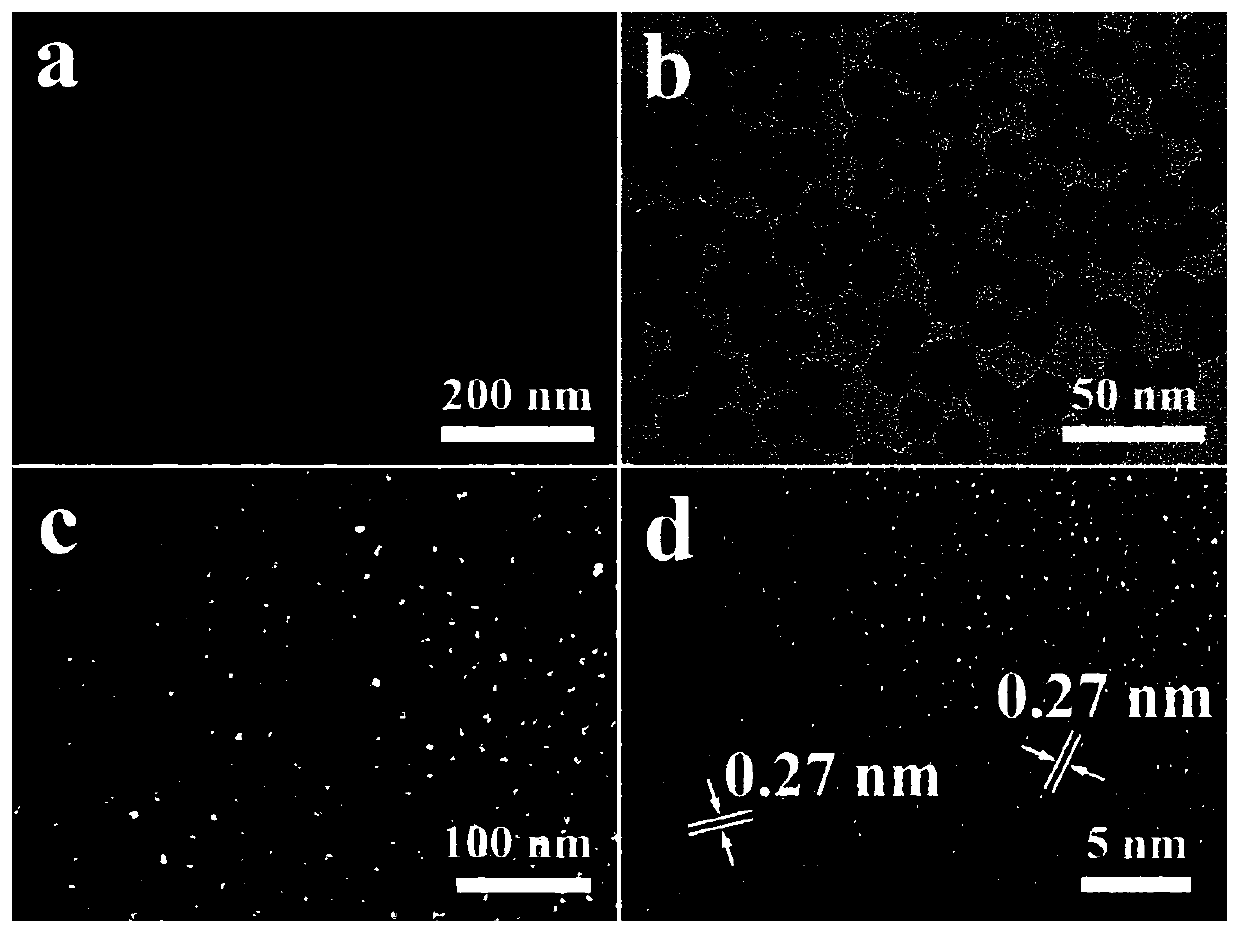

Embodiment 1

[0042] (a) Mix 30ml cyclohexane and 12ml IGEPAL CO-520 under vigorous stirring, add 2.5ml containing H 2 PtCl 6 (0.0021M), Ce(NO 3 ) 3 (0.05M) and Cu(NO 3 ) 2 (0.05M) aqueous solution, stirred for 1h to form the first microemulsion system;

[0043] (b) Mix 20ml cyclohexane and 8ml IGEPAL CO-520 under vigorous stirring, add 4ml containing NaOH (0.25M) and NaBH 4 (0.033M) aqueous solution, stir 1h, form the second microemulsion system;

[0044] (c) Mix the two microemulsion systems obtained in step a and step b, add 1.08ml of concentrated ammonia water after stirring for 6 hours, add 1.25ml tetraethyl orthosilicate after stirring for 2 hours, continue to stir for 2 days, after the reaction ends Add ethanol, centrifuge, wash, and dry to obtain a solid sample;

[0045] (d) Disperse the solid sample obtained in step c in 10ml HNO 3 (1M) solution and stirred for 2 days to remove CuO. The suspension was then centrifuged and washed with a large amount of water and dried to ob...

Embodiment 2

[0047] (a) Mix 30ml cyclohexane and 12ml IGEPAL CO-520 under vigorous stirring, add 2.5ml containing H 2 PtCl 6 (0.0021M), Ce(NO 3 ) 3 (0.05M) and Cu(NO 3 ) 2 (0.03M) aqueous solution, stirred for 1h to form the first microemulsion system;

[0048] (b) Mix 20ml cyclohexane and 8ml IGEPAL CO-520 under vigorous stirring, add 4ml containing NaOH (0.25M) and NaBH 4 (0.033M) aqueous solution, stir 1h, form the second microemulsion system;

[0049] (c) Mix the two microemulsion systems obtained in step a and step b, add 1.08ml of concentrated ammonia water after stirring for 6 hours, add 1.25ml tetraethyl orthosilicate after stirring for 2 hours, continue to stir for 2 days, after the reaction ends Add ethanol, centrifuge, wash, and dry to obtain a solid sample;

[0050] (d) Disperse the solid sample obtained in step c in 10ml HNO 3 (2M) solution and stirred for 2 days to remove CuO. The suspension was then centrifuged and washed with a large amount of water and dried to ob...

Embodiment 3

[0052] (a) Mix 30ml cyclohexane and 12ml IGEPAL CO-520 under vigorous stirring, add 2.5ml containing H 2 PtCl 6 (0.0021M), Ce(NO 3 ) 3 (0.05M) and Cu(NO 3 ) 2 (0.05M) aqueous solution, stirred for 1h to form the first microemulsion system;

[0053] (b) Mix 20ml cyclohexane and 8ml IGEPAL CO-520 under vigorous stirring, add 4ml containing NaOH (0.25M) and NaBH 4 (0.033M) aqueous solution, stir 1h, form the second microemulsion system;

[0054] (c) Mix the two microemulsion systems obtained in step a and step b, add 1.08ml of concentrated ammonia water after stirring for 6 hours, add 1.25ml tetraethyl orthosilicate after stirring for 2 hours, continue to stir for 2 days, after the reaction ends Add ethanol, centrifuge, wash, and dry to obtain a solid sample;

[0055] (d) Disperse the solid sample obtained in step c in 10ml H 2 SO 4 (1M) solution and stirred for 3 days to remove CuO. The suspension was then centrifuged and washed with a large amount of water and dried t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com