A production method and system for high billet strength tungsten powder

A production method and technology for high-pressure blanks, applied in the field of powder metallurgy, can solve the problems of low compaction strength and poor forming performance of tungsten powder, and achieve the effects of good pressing performance, simple preparation steps, and easy control of process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

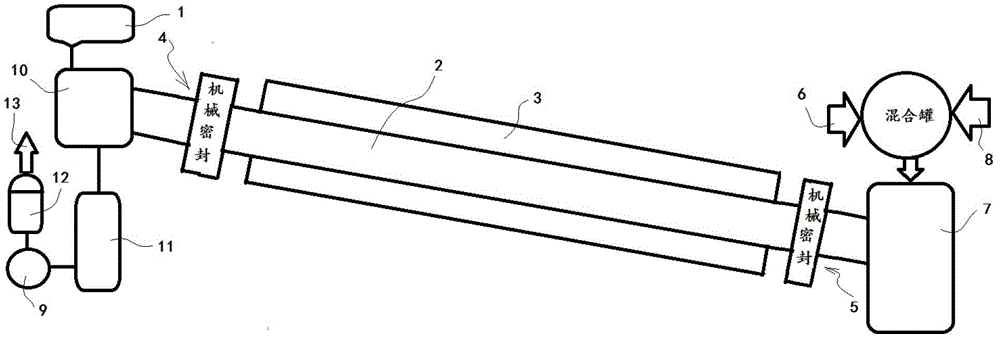

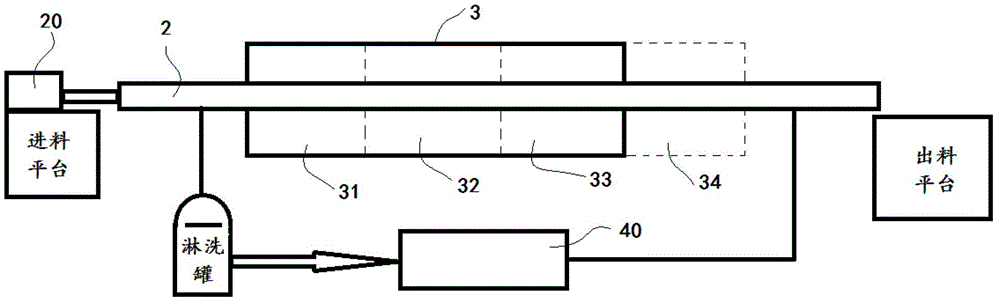

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix industrially pure ammonium paratungstate and purple tungsten oxide at a ratio of 3:7, and place them in a stainless steel boat, with a powder layer thickness of 10mm;

[0030] (2) Place the mixed powder in the step (1) of Example 1 in the high temperature zone of the reduction furnace, raise the temperature at a rate of 10°C / min, keep it at 900°C for 2 hours, and the hydrogen dew point is -45°C ;

[0031] (3) Pass the reduced powder through a 160-mesh sieve to obtain high compacted strength tungsten powder with an average Fsss particle size of 3 μm, and the compacted strength reaches 3.6 MPa.

Embodiment 2

[0033] (1) Place commercially pure ammonium paratungstate powder in a stainless steel boat, and the thickness of the powder layer is 8mm;

[0034] (2) Place the powder in the step (1) of Example 2 in the high temperature area of the reduction furnace, raise the temperature at a rate of 10°C / min, keep it at 950°C for 2 hours, and the hydrogen dew point is -45°C ;

[0035] (3) the powder after reduction in the step (2) of embodiment 2 is crossed 160 mesh sieves, and is recorded as 1# tungsten powder;

[0036] (4) Put commercially pure purple tungsten oxide powder in a stainless steel boat, and the thickness of the powder layer is 10mm;

[0037] (5) Place the powder in the step (4) of Example 2 in the high temperature zone of the reduction furnace, raise the temperature at a rate of 10°C / min, keep it at 850°C for 2 hours, and the hydrogen dew point is -45°C;

[0038] (6) the powder after reduction in the step (5) of embodiment 2 is crossed 160 mesh sieves, is recorded as 2# t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com