Novel isotropic nuclear-grade graphite material and preparation method thereof

A technology of isotropic and graphite materials, applied in the field of graphite materials, can solve problems such as structural stability, different bonding methods, unfavorable nuclear-grade graphite, etc., and achieve the effect of sufficient sources, excellent isotropy, and favorable heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

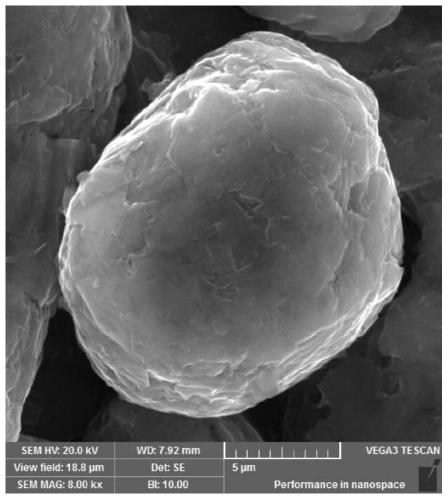

[0053] In this implementation, the mass ratio of binder to aggregate is 0.3:1, and the aggregate is 100% spheroidized natural flake graphite, and the spheroidized natural flake graphite is a purified nuclear pure grade raw material, The fixed carbon content is 99.99%, the D50 particle size is 21.0μm, and the spheroidization degree is 0.85. The SEM image is as follows figure 1 As shown, it shows that the shape of natural flake graphite has been successfully transformed from flake to spherical after spheroidization treatment. The binder is modified asphalt with a softening point of 115°C.

[0054] The preparation method comprises the following steps:

[0055] (1) Spheroidization treatment: place natural flake graphite with a carbon content of 97% in a spheroidization classifier, and obtain a spheroidized graphite with a D50 of 21.0 μm and an average spheroidization degree of 0.85 after crushing, classification and spheroidization treatment. Natural flake graphite;

[0056] (2...

Embodiment 2

[0065] In this implementation, the mass ratio of binder to aggregate is 0.3:1, and the aggregate is a mixture of spheroidized natural flake graphite and petroleum coke, and the mass of spheroidized natural flake graphite and petroleum coke in the mixture The ratio is 1:1. The spheroidized natural flake graphite is a purified nuclear-grade raw material with a fixed carbon content of 99.99%, a D50 particle size of 20.0 μm, and a degree of spheroidization of 0.85. The fixed carbon content of the petroleum coke is 99.95%, boron (B) and gadolinium (Gd) are less than 1ppm, moisture ≤ 0.1%, sulfur ≤ 0.05%, particle size 15μm. The binder is modified asphalt with a softening point of 110°C.

[0066] The preparation method comprises the following steps:

[0067] (1) Spheroidization treatment: put natural flake graphite with a carbon content of 97% in a spheroidization classifier, and after crushing, grading and spheroidization treatment, obtain spheroidized natural flakes with a D50 of...

Embodiment 3

[0077] In this implementation, the mass ratio of binder to aggregate is 0.3:1, and the aggregate is a mixture of spheroidized natural flake graphite and natural microcrystalline graphite, and the spheroidized natural flake graphite and natural microcrystalline graphite in the mixture The mass ratio of crystalline graphite is 3:1, and the spheroidized natural flake graphite is a purified nuclear-grade raw material with a fixed carbon content of 99.99%, a D50 particle size of 15.0 μm, and a spheroidization degree of 0.7. The natural microcrystalline The fixed carbon content in graphite is 99.99%, and the particle size is 20 μm. The binder is modified asphalt with a softening point of 120°C.

[0078] The preparation method comprises the following steps:

[0079] (1) Purification: The raw material is natural flake graphite with a carbon content of 97%, which is purified by a continuous graphitization furnace at a high temperature, with a maximum temperature of 3000°C, and purifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com