Annular inductance element, FeSiCr soft magnetic alloy powder and preparation method of FeSiCr soft magnetic alloy powder applied to annular inductance part

A technology of toroidal inductors and soft magnetic alloys, applied in the manufacture of inductors/transformers/magnets, electrical components, metal processing equipment, etc., can solve the problems of high loss, poor rust resistance, low inductance value of toroidal inductors, etc. Low, good rust resistance, reasonable particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

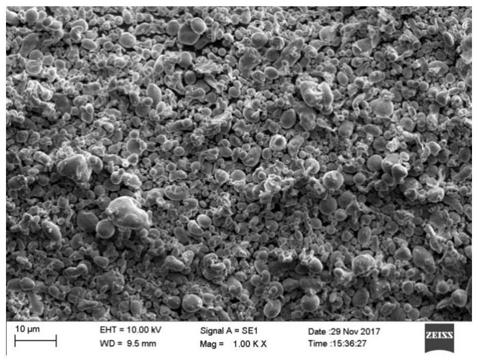

[0050] A method for preparing FeSiCr soft magnetic alloy powder suitable for ring inductors, comprising:

[0051] 1) Medium frequency induction melting: the alloy composition is (89.8wt%) Fe-3.5wt% Si-5.0wt% Cr-1.2wt% Ni-0.5wt% Mo,

[0052] According to the above alloy composition, the raw materials are fed into the corundum crucible in the order of pure iron, ferrochrome, pure nickel, pure molybdenum, and high-purity silicon for smelting. The smelting power is controlled at 200-300KW, and the smelting time is 60.0-70.0 Minutes, when the temperature of the molten steel reaches 1580-1620°C, reduce the power to 100-150KW, use appropriate amount of silicon calcium and lime to deoxidize the molten steel by slagging, the process takes 10.0 minutes, then clean the slag, start the pump and pour steel;

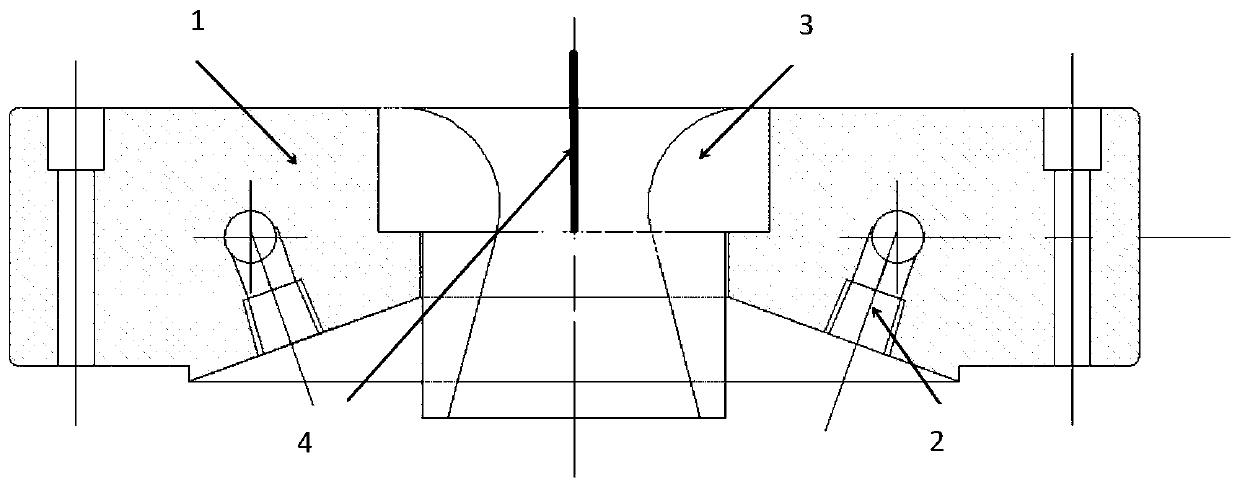

[0053] 2) Water-air combined atomization: Nitrogen is used as the process protection atmosphere, and the nitrogen flow rate is 25.0m3 / h; the atomization process adopts 40° / 30° primary...

Embodiment 2

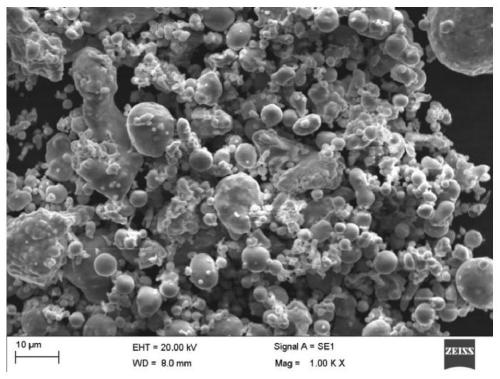

[0058] The difference between this embodiment 2 and embodiment 1 is: a kind of FeSiCr soft magnetic alloy powder composition suitable for annular inductance prepared in this embodiment 2 is adjusted, and the prepared alloy powder alloy composition is: (86.3wt%) Fe-7.0wt%Si-5.0wt%Cr-1.2wt%Ni-0.5wt%Mo, the above components are all in mass percentage.

Embodiment 3

[0060] The difference between this embodiment 3 and embodiment 1 is that: in this embodiment 3, a combined water-air atomization process suitable for FeSiCr soft magnetic alloy powder for ring inductors is prepared by adjusting. The specific atomization process is as follows: nitrogen is used as the process protection atmosphere, and the nitrogen flow rate is 25.0m3 / h; 40° / 30° primary and secondary spraying plates are used, and double V-shaped nozzles; the leakage hole size at the bottom of the molten steel tundish is 3.5mm, The atomized water pressure is 110MPa, and the atomized water flow rate is 130L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com