Method for preparing nickel-coated powder by carbonyl vapor deposition

A technology of vapor deposition and nickel coating, applied in the field of nickel coating powder, can solve the problems of incomplete powder coating, low decomposition rate of nickel carbonyl, unstable product quality, etc., and achieve uniform particles, good dispersion and large surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

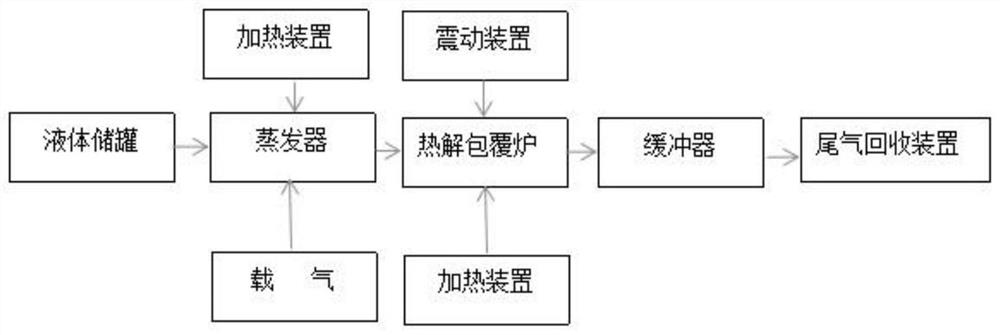

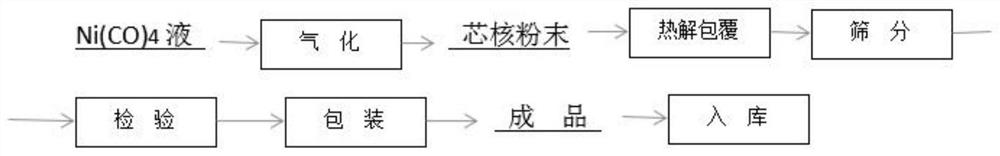

[0029] A method for preparing nickel-coated powder by carbonyl vapor deposition, the method being applied to a nickel coating process, comprising the following steps:

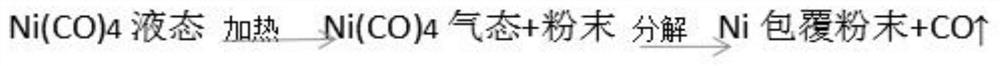

[0030] 1) In the preparation stage, the coated material is placed in a vibrating pyrolysis coating furnace, the coated material is the coated material, and the coated material can be metal or non-metallic material, carbon monoxide and metal nickel are placed in the normal pressure And under the condition of 40 ℃, the obtained nickel carbonyl liquid is stored in the liquid storage tank for subsequent use;

[0031] 2) Put the nickel carbonyl liquid prepared in step (1) into the evaporator, and heat it to 150° C. through the heating device, the nickel carbonyl liquid is vaporized into nickel carbonyl gas, and at the same time, put the carrier gas into the evaporator;

[0032] 3) The carrier gas and nickel carbonyl gas enter the vibration pyrolysis coating furnace from the evaporator. The temperature of the nickel ...

Embodiment 2

[0036] A method for preparing nickel-coated powder by carbonyl vapor deposition, the method being applied to a nickel coating process, comprising the following steps:

[0037] 1) In the preparation stage, the coated material is placed in a vibrating pyrolysis coating furnace, the coated material is the coated material, and the coated material can be metal or non-metallic material, carbon monoxide and metal nickel are placed in the normal pressure And under the condition of 100 ℃, the obtained nickel carbonyl liquid is stored in the liquid storage tank for subsequent use;

[0038] 2) Put the nickel carbonyl liquid prepared in step (1) into the evaporator, and heat it to 300° C. through the heating device, the nickel carbonyl liquid is vaporized into nickel carbonyl gas, and at the same time, put the carrier gas into the evaporator;

[0039] 3) The carrier gas and nickel carbonyl gas enter the vibration pyrolysis coating furnace from the evaporator. The temperature of the nickel...

Embodiment 3

[0043] A method for preparing nickel-coated powder by carbonyl vapor deposition, the method being applied to a nickel coating process, comprising the following steps:

[0044] 1) In the preparation stage, the coated material is placed in a vibrating pyrolysis coating furnace, the coated material is the coated material, and the coated material can be metal or non-metallic material, carbon monoxide and metal nickel are placed in the normal pressure And under the condition of 70 ℃, the obtained nickel carbonyl liquid is stored in the liquid storage tank for subsequent use;

[0045] 2) Put the nickel carbonyl liquid prepared in step (1) into the evaporator, heat it to 225° C. through the heating device, the nickel carbonyl liquid is vaporized into nickel carbonyl gas, and simultaneously put the carrier gas into the evaporator;

[0046] 3) The carrier gas and nickel carbonyl gas enter the vibration pyrolysis coating furnace from the evaporator. The temperature of the nickel carbony...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com