Method for preparing copper or nickel powder and electrolysis device based on same

A technology of copper powder and nickel powder, which is applied in the electrolysis process, electrolysis components, electrodes, etc., to achieve the effect of improving work efficiency, reducing labor intensity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

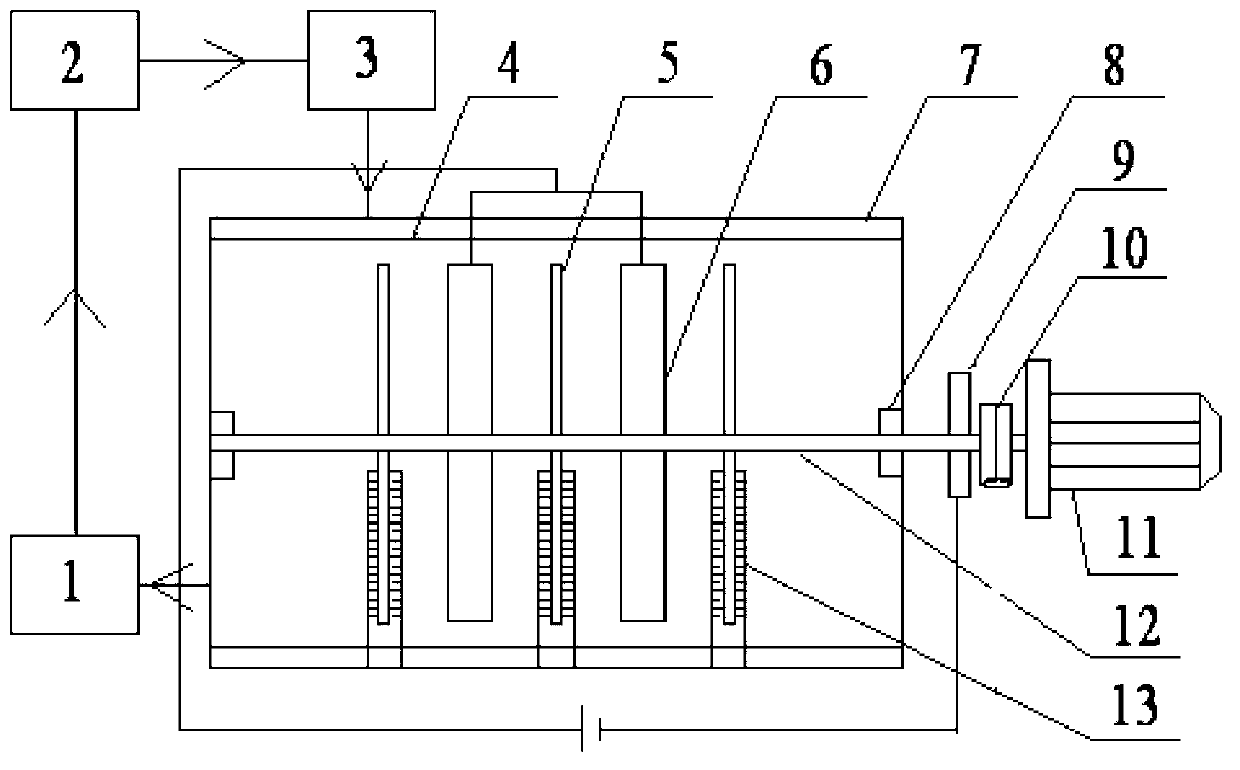

[0022] Example 1, such as figure 1 Shown, a kind of method for preparing copper powder and device thereof are as follows:

[0023] a. prepare copper sulfate electrolyte, copper ion concentration 0.08mol\L, pH=3, the dispersant sodium hexametaphosphate added accounts for 0.1% of the mass percentage concentration of copper sulfate electrolyte;

[0024] b. Inject the prepared electrolyte into the electrolytic cell 4 and the high level tank 3;

[0025] c. Clean up "copper rice" or copper turning chips, and wash with deionized water;

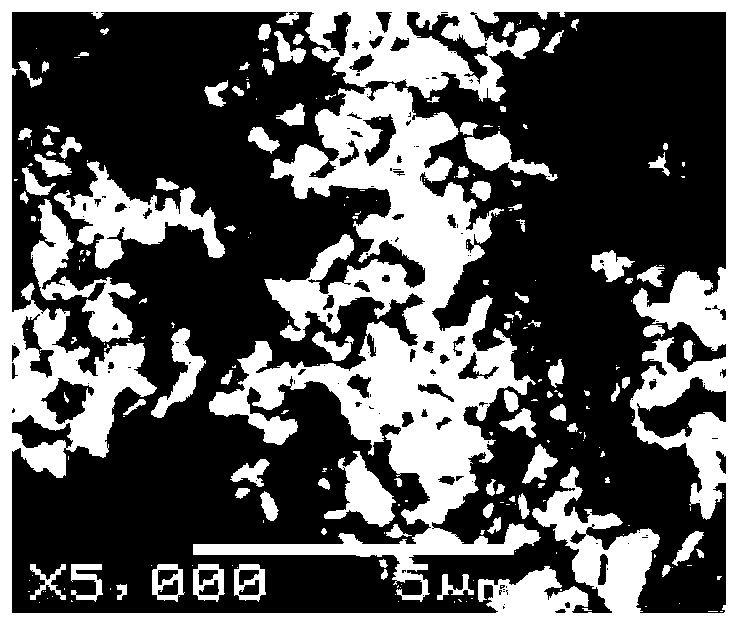

[0026] d. The cleaned copper raw material is directly loaded into the electrolysis frame 6 as a sacrificial anode, and is electrolyzed through graphite electrodes. As the electrolysis process progresses, copper raw materials are added every 1 to 1.2 hours. The electrolytic process conditions are: current density 5A\ dm 2 , the cathode group plate 5 is made of 316 stainless steel plate, the electrolysis temperature is 27-33°C, and the distance betw...

Embodiment 2

[0033] Example 2, such as figure 1 Shown, a kind of method for preparing nickel powder and electrolytic device thereof are as follows:

[0034] a. Prepare nickel chloride electrolyte, use nickel chloride hexahydrate as electrolyte, adjust acidity with hydrochloric acid and ammonia water, nickel ion concentration is 0.04mol / L, pH=4, NH 4 Cl is 10g / L, and the added dispersant polyvinylpyrrolidone accounts for 0.05% of the mass percentage concentration of the nickel chloride electrolyte;

[0035] b. Inject the prepared electrolyte into the electrolytic cell 4 and the high level tank 3;

[0036] c. Clean the nickel plate or recycled waste nickel block, and wash it with deionized water;

[0037] d. The cleaned nickel plate or recycled waste nickel block is directly loaded into the electrolysis frame 6 as a sacrificial anode, and electrolysis is carried out through graphite electrodes. As the electrolysis process progresses, nickel raw materials are added every 1 to 1.2 hours. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com