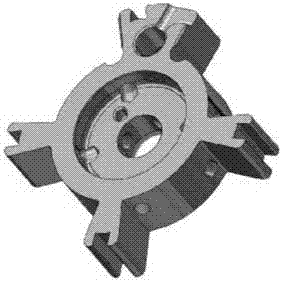

A preparation method of powder metallurgy aluminum alloy phaser rotor

A powder metallurgy and aluminum alloy technology, which is used in the preparation of powder metallurgy aluminum alloy phaser rotors and the field of engine variable valve timing systems, can solve the problem that alloy elements cannot be changed at will, easy to produce pores, shrinkage holes, and affect the mechanical properties of parts. and other problems, to achieve the effect of high utilization rate of aluminum alloy raw materials, fast pressing speed and long tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

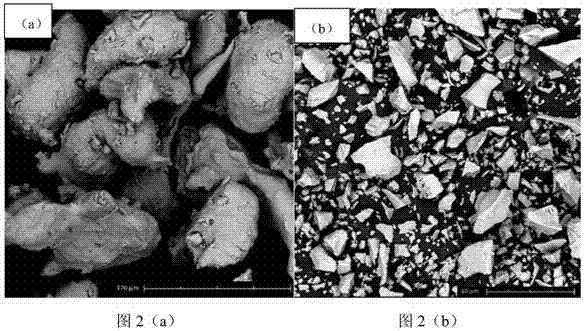

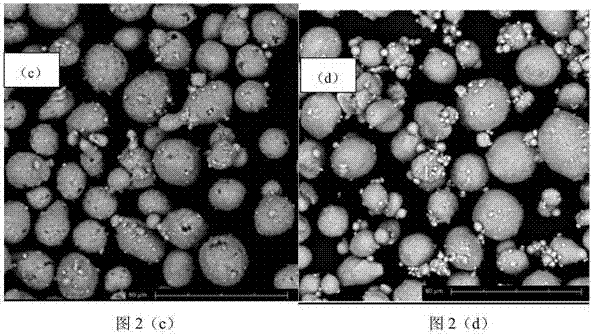

Image

Examples

Embodiment 1

[0036] 1. Mix aluminum powder, high-alloy master powder (Al-Mg alloy master powder, Al-Si alloy master powder, Al-Fe alloy master powder), copper powder, nickel powder and organic lubricant according to the following mass ratio, so that The mass percentage content of each element in the total composition is: copper 2.0%, magnesium 2.0%, iron 1.0%; nickel 1.8%, silicon 0.25%, wax lubricant: 1.0%, unavoidable impurities not exceeding 2% , and the balance is aluminum; a double-cone mixer is used for mixing, the speed of the mixer is 15rpm, and the mixing time is 30min.

[0037] 2. Press and form the uniformly mixed rotor material powder in the designed mold under a pressure of 250MPa to obtain a powder metallurgy aluminum rotor green body. The green body has a forming density of 2.60g / cm 3 .

[0038] 3. Place the pressed powder metallurgy rotor on the mesh belt of the continuous sintering furnace for sintering. The sintering temperature is 595°C, the sintering atmosphere is hig...

Embodiment 2

[0048] 1. Mix aluminum powder, high-alloy master powder (Al-Mg alloy master powder, Al-Si alloy master powder, Al-Fe alloy master powder), copper powder, nickel powder and organic lubricant according to the following mass ratio, so that The mass percentage content of each element in the total composition is: copper 3.0%, magnesium 1.8%, iron 1.2%; nickel 2.0%, silicon 0.50%, wax lubricant: 1.0%, unavoidable impurities not exceeding 2% , and the balance is aluminum; a double-cone mixer is used for mixing, the speed of the mixer is 15rpm, and the mixing time is 30min.

[0049] 2. Press the uniformly mixed rotor material powder into the designed mold under the pressure of 400MPa to obtain the powder metallurgy aluminum rotor green body. The green body has a forming density of 2.65g / cm 3 .

[0050] 3. Place the pressed powder metallurgy rotor on the mesh belt of the continuous sintering furnace for sintering. The sintering temperature is 600°C, the sintering atmosphere is high-p...

Embodiment 3

[0057] 1. Mix aluminum powder, high-alloy master powder (Al-Mg alloy master powder, Al-Si alloy master powder, Al-Fe alloy master powder), copper powder, nickel powder and organic lubricant according to the following mass ratio, so that The mass percentage content of each element in the total composition is: copper 3.0%, magnesium 1.8%, iron 1.2%; nickel 2.0%, silicon 0.50%, amide organic lubricant: 1.0%, no more than 2% unavoidable Impurities, the balance is aluminum; a double cone mixer is used for mixing, the speed of the mixer is 15rpm, and the mixing time is 30min.

[0058] 2. Press and form the uniformly mixed rotor material powder in the designed mold under a pressure of 250MPa to obtain a powder metallurgy aluminum rotor green body. The green body has a forming density of 2.60g / cm 3 .

[0059] 3. Place the pressed powder metallurgy rotor on the mesh belt of the continuous sintering furnace for sintering. The sintering temperature is 595°C, the sintering atmosphere is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com