Mixture preparation process

A preparation process and a technology for mixing materials, applied in the field of powder metallurgy, can solve problems such as uneconomical, and achieve the effects of brittle logistics, uniform metallographic structure, prevention of oxidation and/or excellent mixing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

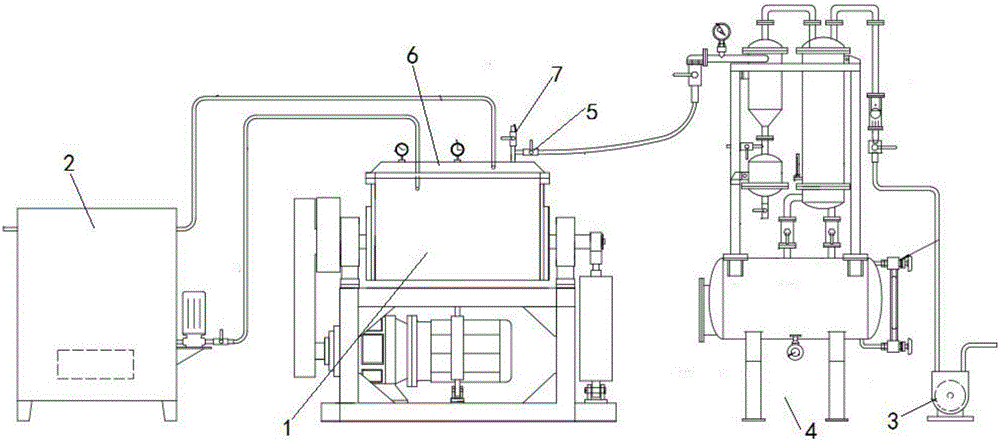

[0074] Such as figure 1 Shown device, the specific embodiment of the present invention is as follows:

[0075] Step a, mixing 5 microns of tungsten carbide and cobalt powder into a mixture, wherein the weight of 5 microns of tungsten carbide accounts for 92% of the total mixture weight, and the weight of cobalt powder accounts for 8% of the total mixture weight. The weight of the material is 280Kg; the PEG forming agent and the WC raw material are mixed in such a way that the PEG forming agent accounts for 1.5% to 2.5% of the total weight of the mixture to form a mixture. After mixing, add it to a ball mill for wet grinding for 15 to 20 hours. Alcohol is added to improve the wet grinding efficiency and the fineness of the mixture after wet grinding is uniform; specifically, the PEG forming agent can be set to account for 1.5% or 2.5% or 2% of the weight of the mixture according to actual needs, and the wet grinding The time is set according to the state of the mixture after g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com