Winding core and coil component

A wire winding and core technology, which is applied to transformer/inductor components, transformer/inductor coils/windings/connections, electrical components, etc., and can solve problems such as the deviation of the shape of the winding core 5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

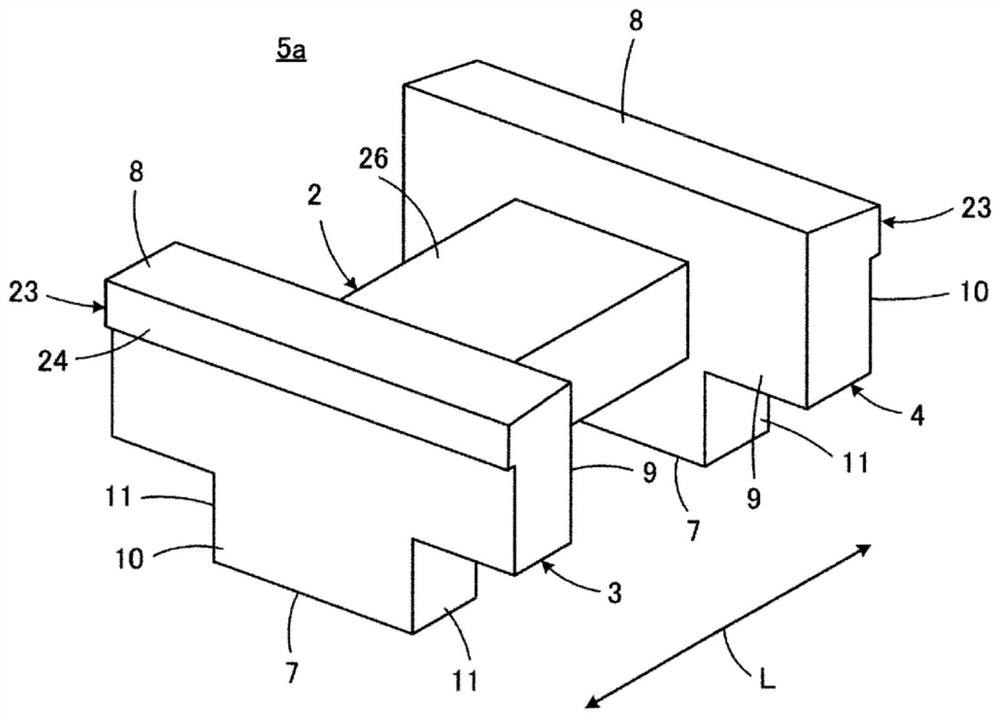

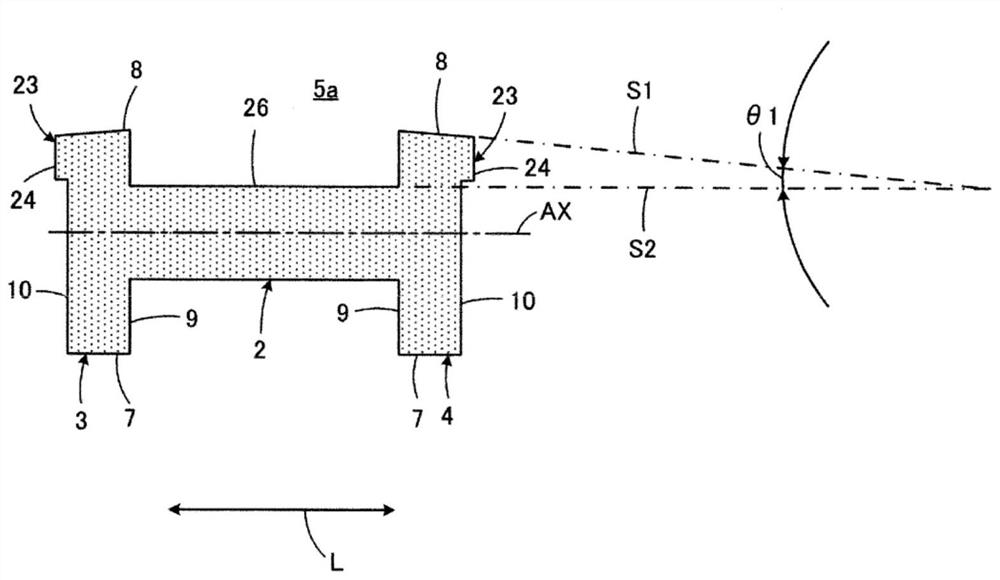

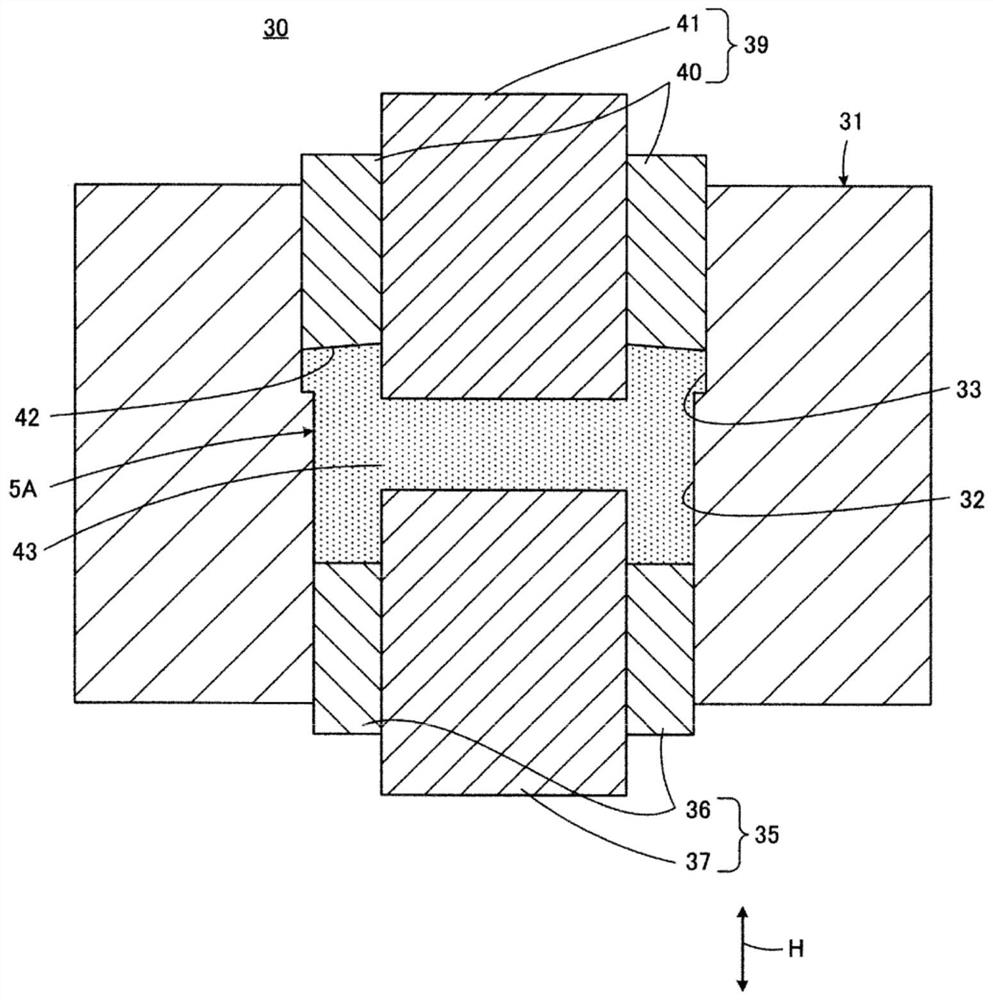

[0030] As mentioned above, Figure 5 It is a figure which shows the coil component 1 described in patent document 1, and in Figure 5 In the coil component 1 shown, the winding core 5 is replaced by figure 1 The shown member of the winding core 5a is a coil member according to one embodiment of the present invention. Thus, in figure 1 and figure 2 on the basis of the Figure 5 Next, the winding core 5a according to the first embodiment of the present invention and the coil component provided therewith will be described. In addition, in the following description, for the Figure 5 elements equivalent to those shown, use the same Figure 5 The reference numbers shown have the same reference numbers.

[0031] In the first embodiment of the present invention, the coil component also constitutes, for example, a common mode choke coil, and also includes the winding core 5a. The winding core 5a has: a winding core portion 2 extending along the longitudinal direction L; 1st end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com