Mixed powder for powder metallurgy, sintered body and method for producing sintered body

A technology of powder metallurgy and mixed powder, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems such as not easy to oxidize, and achieve the effect of excellent compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

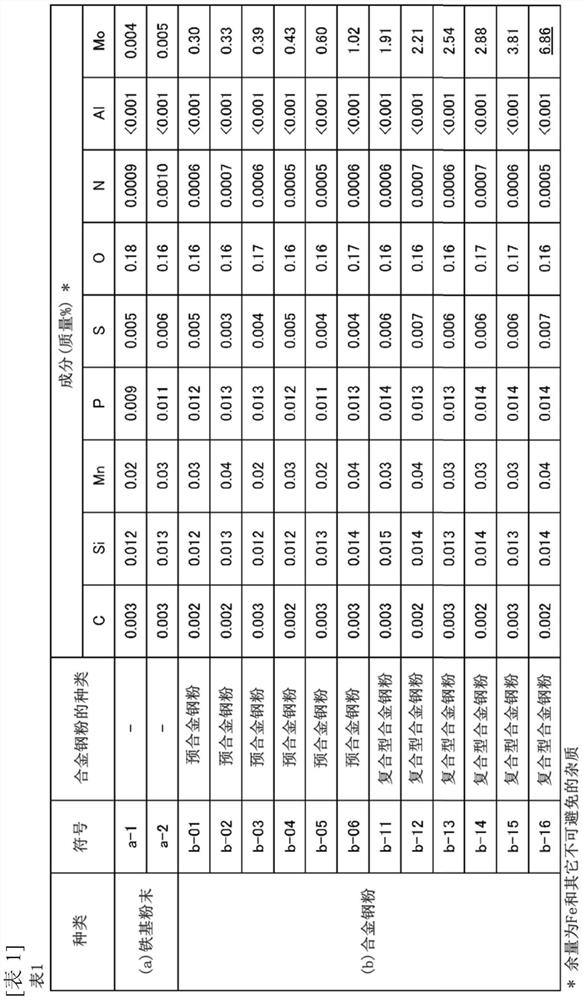

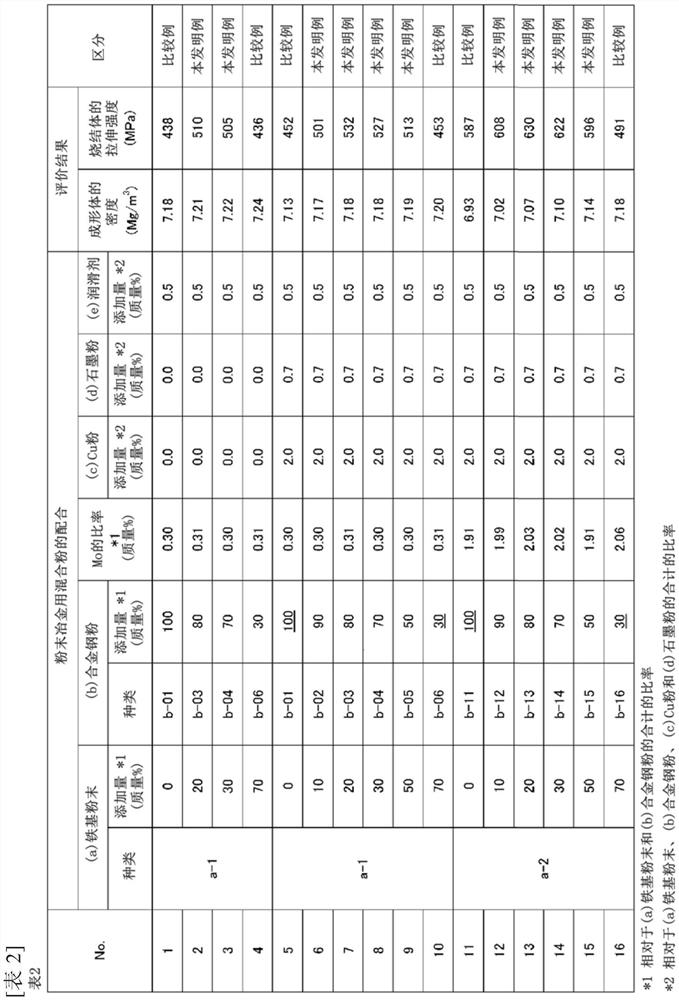

[0088] Mixed powders for powder metallurgy were produced using iron-based powders and alloy steel powders containing only Si and Mn as unavoidable impurities, and their properties were evaluated. The specific steps are as follows.

[0089] (a) Iron-based powders were produced by performing a final reduction treatment at 900°C for 60 minutes in a hydrogen atmosphere to decarburize and deoxidize iron powders produced by the water atomization method, and crushing the resulting lumps , from which it is produced. Table 1 shows the component composition of the obtained iron-based powder. In addition, each element shown in Table 1 is an element contained as an unavoidable impurity in iron-based powder.

[0090] As (b) alloy steel powder, two types of pre-alloyed steel powder and composite alloy steel powder were used. The pre-alloyed steel powder is produced by the same method as the iron-based powder described above except that a raw material containing Mo is used as the melt for...

Embodiment 2

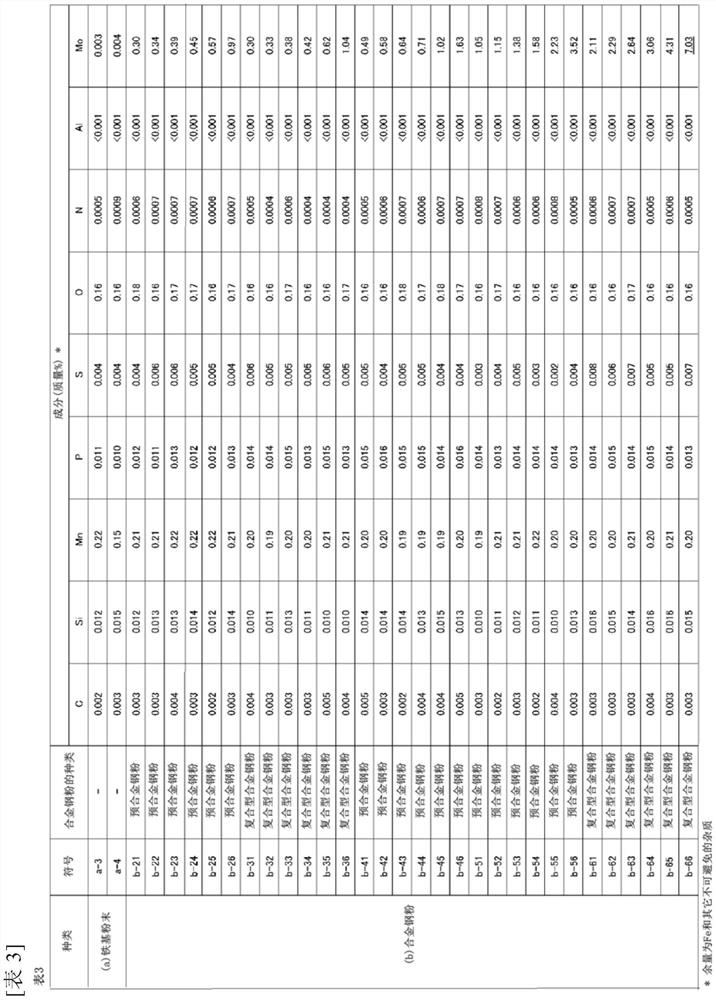

[0103] Mixed powders for powder metallurgy were produced in the same manner as in Example 1 except for using Mn-containing iron-based powders and alloy steel powders, and their performances were evaluated. Table 3 shows the composition of the iron-based powder and alloy steel powder used, and Table 4 shows the compounding ratio of each component and the evaluation results.

[0104] From the results shown in Table 4, it can be seen that, similar to the case of Example 1, as the mixing ratio of the iron-based powder increases, the molding density increases, and the tensile strength first increases and then decreases. In addition, in the examples satisfying the conditions of the present invention, 7.00 Mg / m was obtained 3 Above molding density and above 500MPa tensile strength.

[0105]

[0106]

Embodiment 3

[0108] Mixed powders for powder metallurgy were produced by the same method as in Example 1 except for using iron-based powders and alloy steel powders containing Si and Mn, and their performances were evaluated. Table 5 shows the composition of the iron-based powder and alloy steel powder used, and Table 6 shows the compounding ratio of each component and the evaluation results.

[0109] From the results shown in Table 6, it can be seen that, as in Examples 1 and 2, as the mixing ratio of the iron-based powder increases, the molding density increases, and the tensile strength first increases and then decreases. In addition, in the examples satisfying the conditions of the present invention, 7.00 Mg / m was obtained 3 Above molding density and above 500MPa tensile strength. In addition, it can be seen that, in Examples 2 and 3 using raw material powders containing one or both of Si and Mn, the sintered body compared with Example 1 while maintaining a high density of the molded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com