Hot-bending forming machine for mobile phone glass and watch surface covers

A molding machine and glass technology, applied in glass molding, glass remolding, glass manufacturing equipment, etc., can solve the problems affecting the quality and service life of mobile phone glass, destroying the chemical structure of glass, discontinuous production interval, etc. Good uniform heating effect, high degree of automation, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

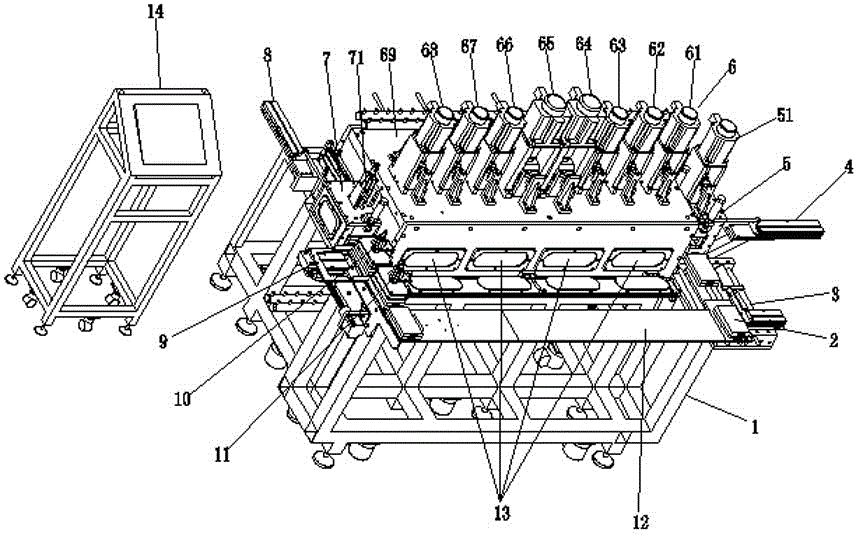

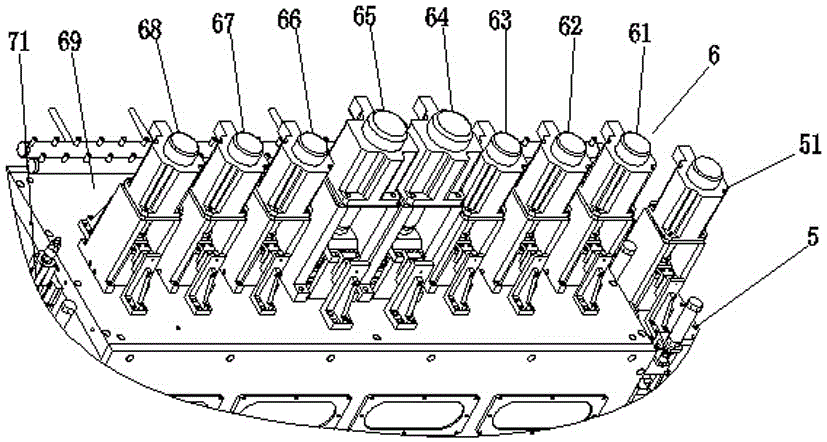

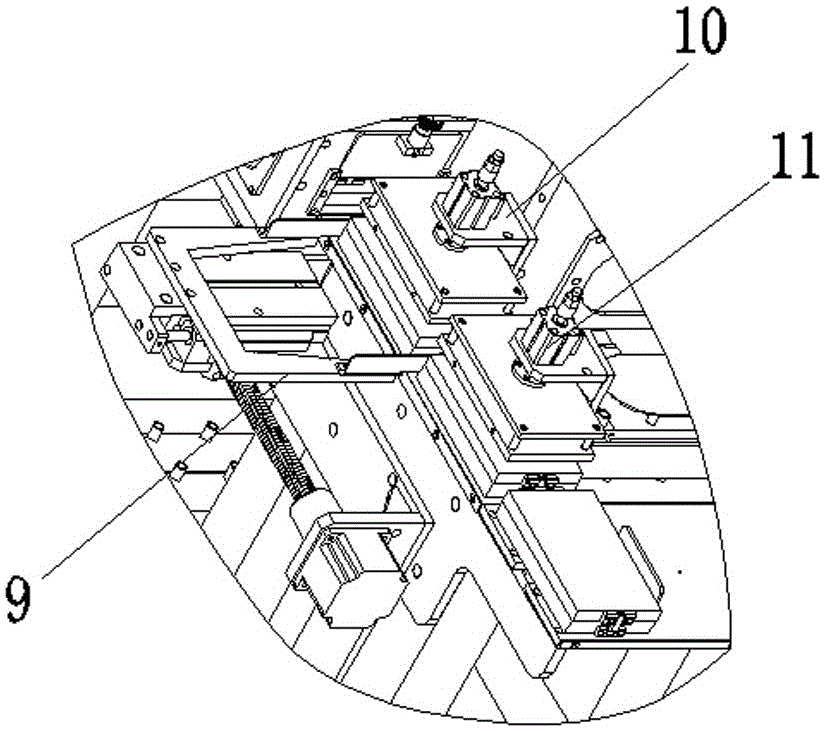

[0027] Such as Figure 1 to Figure 5 As shown, a mobile phone glass and watch cover thermal bending forming machine includes a frame 1 and an operation console 14, the operation console 14 and the frame 1 are independently arranged, and the frame 1 is provided with a forming part 7 and a mold placement platform 12, the mold placement platform 12 is located in front of the molding part 7, the molding part 7 includes a molding bin 69, one end of the molding bin 69 is an inlet end, and the other end is an outlet end, the molding The warehouse 69 is provided with mold preheating mechanism 61-63, forming mechanism 64, shaping mechanism 65, mold precooling mechanism 66-67 and mold first cooling mechanism 68 successively fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com