MVR evaporative concentration and crystallization process for extracting lithium from salt lake brine

A technology of evaporative concentration and salt lake brine, which is applied in the field of MVR evaporative concentration and crystallization process, can solve the problems of high operating cost and high energy consumption in the evaporative concentration section, and achieve the effect of stable system, low operating cost and good controllability of output concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0050] The MVR evaporation concentration crystallization process for extracting lithium from salt lake brine according to the present invention provides several salt lake brine concentration crystallization methods, which can crystallize part of sodium chloride, reduce energy consumption, and reduce operating costs.

[0051] In order to achieve the above object, the MVR evaporation and concentration process of salt lake brine according to the present invention includes three parts: stock solution preheating, MVR evaporation concentration crystallization and MVR vapor compression. The specific implementation method is as follows:

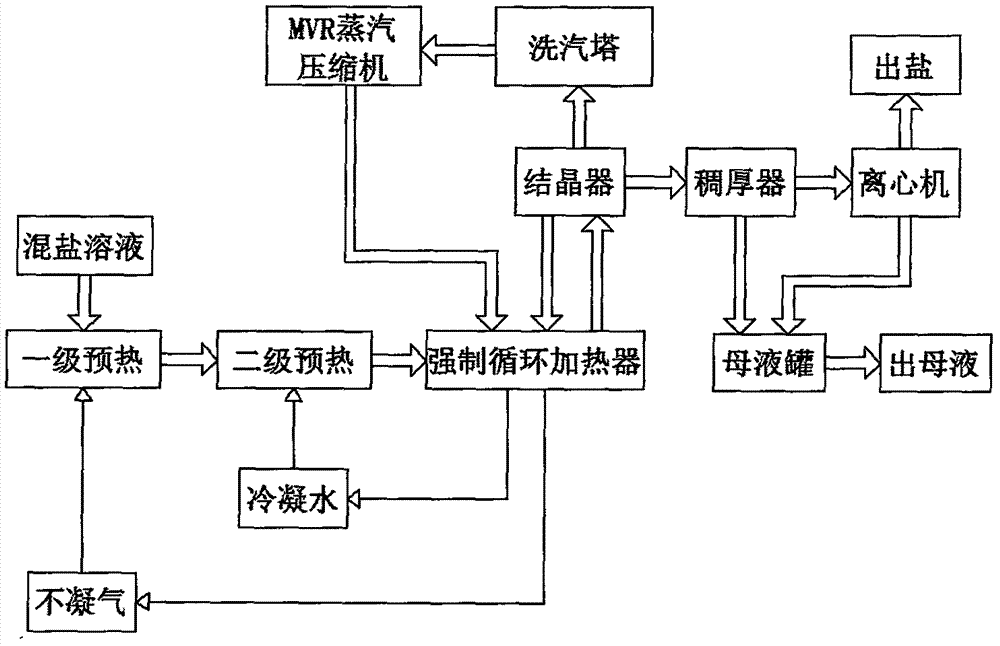

[0052] figure 1 It is a flow chart of the one-stage forced circulation MVR evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com